Pouring cup model for investment casting and using method thereof

A technology of investment casting and sprue cups, which is applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of substandard product quality, casting slag inclusions, pores, etc., to control costs and improve casting slag inclusions , The effect of reducing the probability of air inclusion in castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

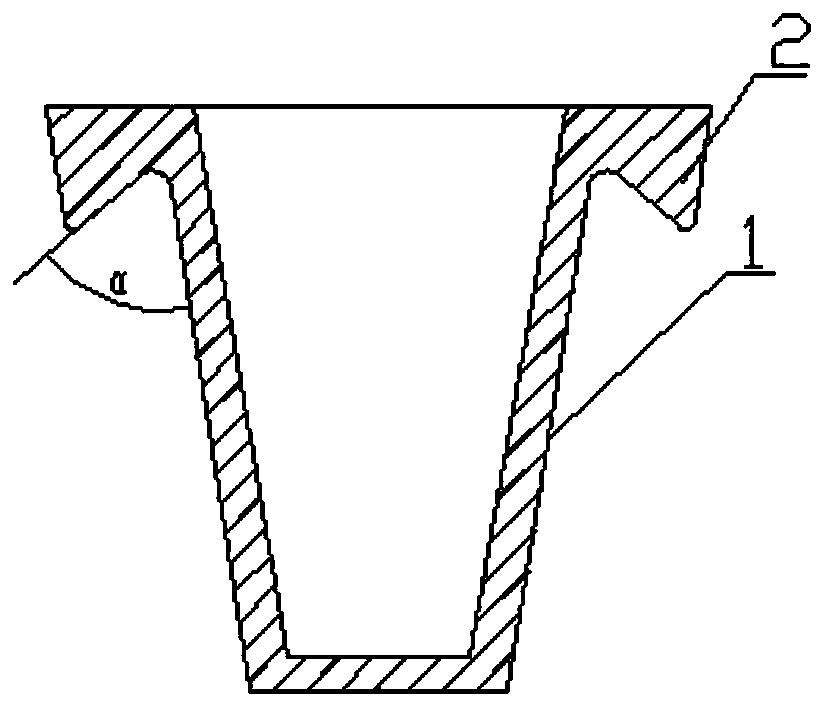

Embodiment 1

[0024] In the sprue cup model used for investment casting in this embodiment, the material of the model body 1 and the flanging 2 are both zirconium sound sand, and the angle α between the flanging 2 and the outer surface of the model body 1 is 30°, and the model body The wall thickness of 1 is T=10㎜, the model body 1 is a hollow circular platform, and the section is made along the longitudinal direction of the circular platform. The inner surface and outer surface of the model body 1 respectively form the first inverted trapezoid and the second inverted trapezoid in the longitudinal section , the upper side length L of the second inverted trapezoid 1 50㎜, bottom length L 2 90㎜, height H 1 is 150mm, the length of the upper side of the first inverted trapezoid is L 3 38㎜, bottom length L 4 68.4㎜, height H 2 is 140㎜; the longitudinal section of the flange 2 is a triangle, the length l of the base of the triangle is 25㎜, and the height h is 30㎜. There is a circular arc trans...

Embodiment 2

[0031] The difference from Example 1 is that the sprue cup model used for investment casting in this example has an angle α between the flanging 2 and the outer surface of the model body 1 = 20°, and the wall thickness of the model body 1 is T = 10°. ㎜, the model body 1 is a hollow circular platform, and the section is made along the longitudinal direction of the circular platform. The inner surface and the outer surface of the model body 1 respectively form the first inverted trapezoid and the second inverted trapezoid in the longitudinal section, and the second inverted trapezoid Length of upper side L 1 60㎜, bottom length L 2 108㎜, height H 1 is 180mm, the length of the upper side of the first inverted trapezoid is L 3 45㎜, bottom length L 4 81㎜, height H 2 is 170㎜; the longitudinal section of the flange 2 is a triangle, the length l of the base of the triangle is 30㎜, and the height h is 40㎜. There is a circular arc transition section with a radius R of 5 mm. All the...

Embodiment 3

[0033] What is different from Example 1 is that the sprue cup model used for investment casting in this example has an angle α between the flanging 2 and the outer surface of the model body 1 = 80°, and the wall thickness of the model body 1 is T = 8 ㎜, the model body 1 is a hollow quadrangular prism with a large upper opening and a small lower opening. The section is made along the longitudinal direction of the quadrangular prism. The inner and outer surfaces of the model body 1 respectively form the first inverted trapezoid and The second inverted trapezoid, the length of the upper side of the second inverted trapezoid is L 1 40㎜, bottom length L 2 72㎜, height H 1 is 120mm, the length of the upper side of the first inverted trapezoid is L 3 35㎜, bottom length L 4 63㎜, height H 2 is 112㎜; the longitudinal section of the flange 2 is a triangle, the length l of the base of the triangle is 20㎜, and the height h is 20㎜. There is a circular arc transition section with a radiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com