A cryogenically treated aluminum matrix composite material reinforced by high-entropy alloy particles and its preparation method

A technology of aluminum-based composite materials and high-entropy alloys, which is applied in the field of cryogenically treated aluminum-based composite materials reinforced by high-entropy alloy particles and its preparation, can solve the problems of small size, poor performance of alloy materials, and high cost, and achieve grain boundaries Smooth, reliable coercive force, high energy product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

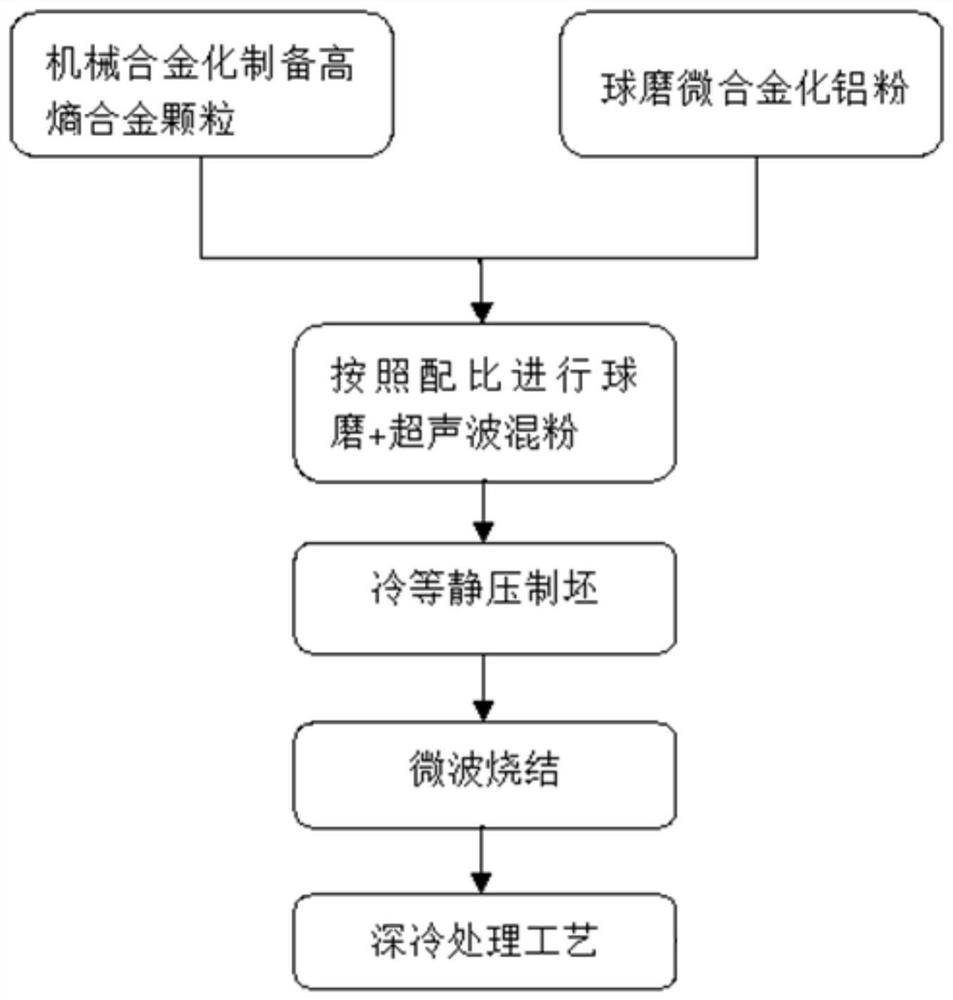

[0036] According to this embodiment figure 1 The process shown in the preparation of aluminum matrix composites, specifically:

[0037] (1) Raw material selection, the purity of the prepared high-entropy alloy metal powder is 99.9% and above, the particle size of the powder is not greater than 45 μm, and the high-entropy alloy components are compounded according to the molar ratio; the purity of the prepared pure aluminum powder is 99.9wt% and above , The particle size of pure aluminum powder is not more than 300μm, and the metal powder is weighed by an electronic balance with an accuracy of 0.01g. The high-entropy alloy particles are reinforcements, and the atomic ratio expression of the selected high-entropy alloy components is FeCoNi 1.5 CrCuM, M is Nd and B;

[0038] The aluminum matrix is an aluminum alloy added with microalloying elements Ti, La, Sc and Sm. The microalloying elements added to pure aluminum are Ti, La, Sc and Sm; the microalloying elements are weighe...

Embodiment 2

[0051] Preparation of high-entropy alloy powder: the mass content of high-entropy alloy powder was 40wt% and the mass content of aluminum matrix alloy powder was 60wt% when the experimental design was mixed; the rest of the preparation method was the same as that of Example 1.

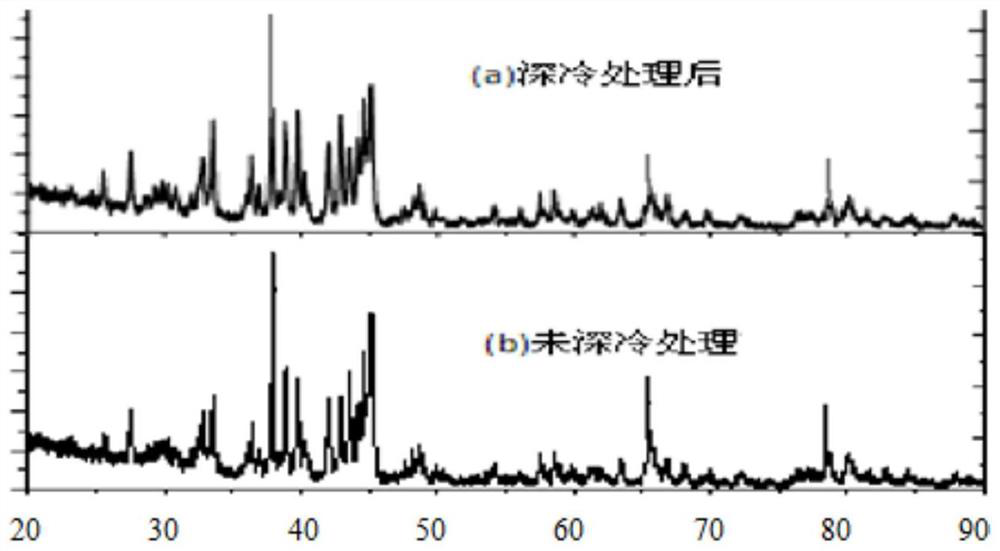

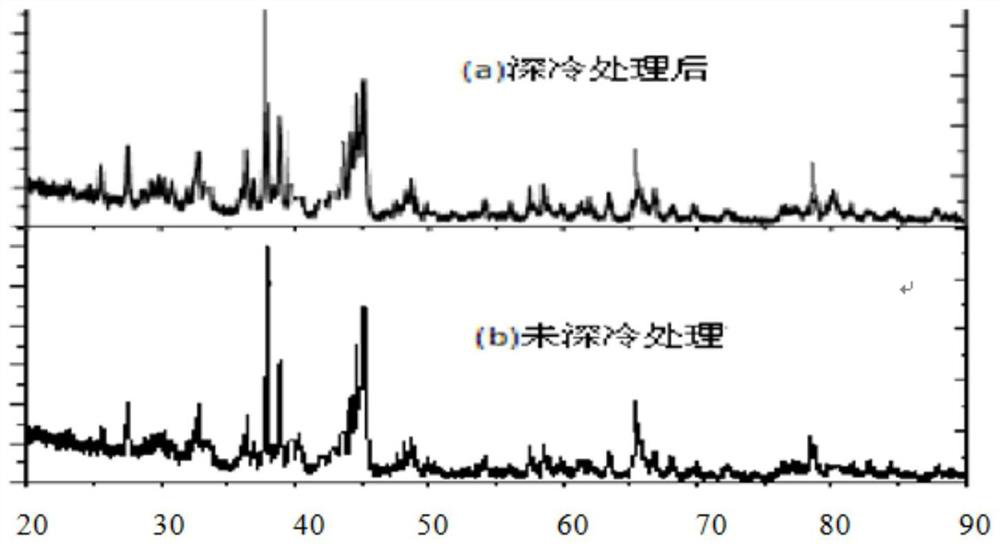

[0052] a. From the microstructure diagram Figure 5 It can be seen that the cryogenically treated aluminum-based composite material with a mass content of 40wt% high-entropy alloy reinforced according to the preparation method of Example 1 is compared with the sample in Example 1, and the content of high-entropy alloy phase in the aluminum-based composite material is obviously increased. . image 3 Shown is the XRD before and after cryogenic treatment in the present embodiment, and XRD analysis finds, marked the main magnetic phase Nd that some diffraction peaks change 2 Fe 14 B and the non-main magnetic phase, by comparing the PDF cards, it can be found that the main magnetic phase Nd 2 Fe 14 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com