Carriage sealing device and muck vehicle

A technology for sealing devices and compartments, which is applied to motor vehicles, transportation and packaging, and vehicles used for freight transportation, etc. It can solve problems such as urban environmental pollution, low vehicle attendance, and resettlement of shed poles, achieving good airtight effects and convenient operation , the effect of smooth opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

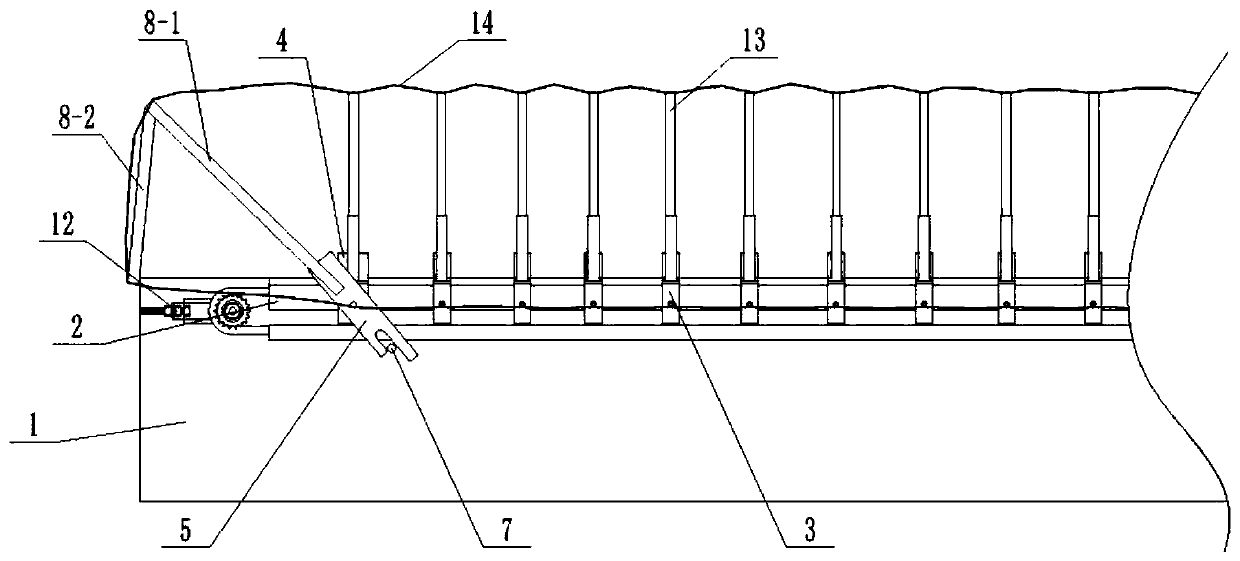

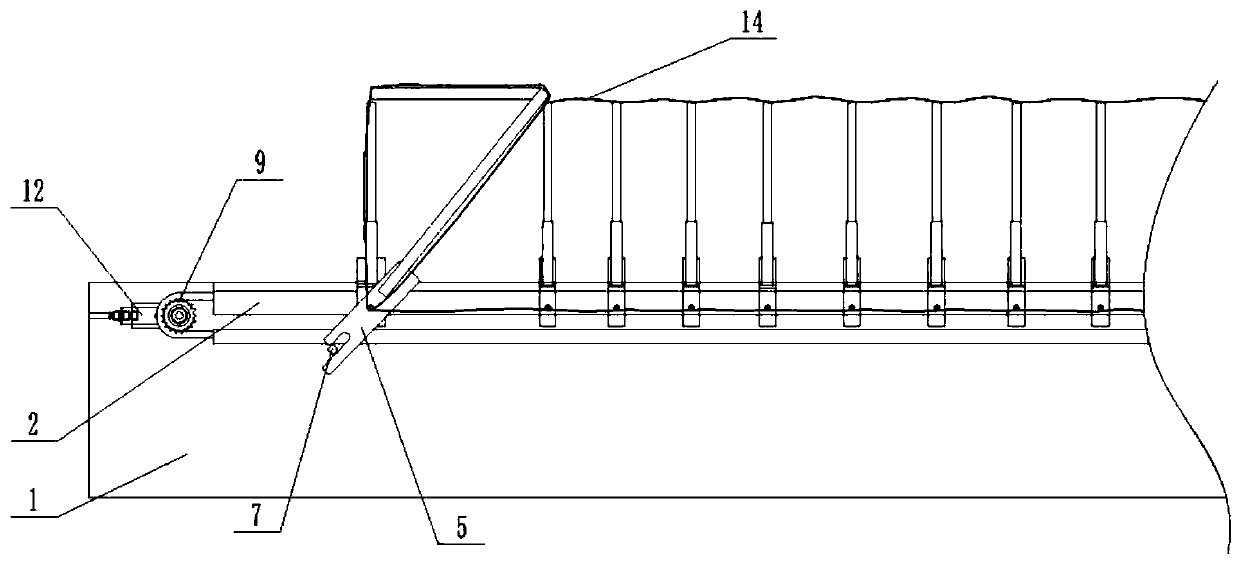

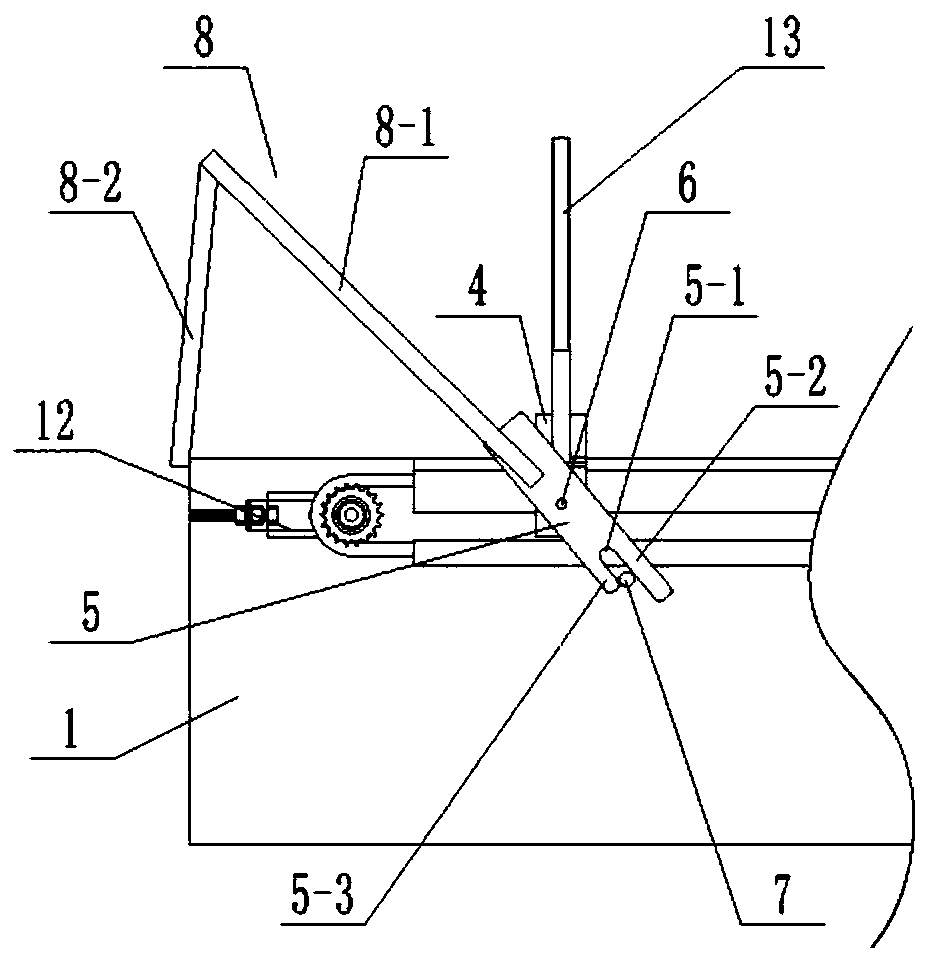

[0045] Such as figure 1 with Picture 11 As shown, a compartment sealing device includes a compartment body 1, a sliding assembly and a transmission assembly arranged on the compartment body 1, the sliding assembly comprising a guide rail 2 and a guide rail 2 A plurality of trolleys 3, the trolley 3 includes a tail trolley 4 near the tail of the carriage body 1, and is characterized in that it also includes a tail buckle assembly, the tail buckle assembly includes a shift fork 5, a tail scaffold 8 and a fork pin 6 arranged on the outside of the tail block 4, the fork 5 is rotatably sleeved on the fork pin 6, the upper end of the fork 5 and the tail scaffold 8 For connection, a U-shaped fork 5-1 is provided at the lower end, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com