Heating furnace body and semiconductor device

A heating furnace and heating zone technology, which is applied in the field of heating furnace body and semiconductor equipment, can solve the problems of reduced production capacity, increased process cost, and poor uniformity of film thickness, so as to improve heating efficiency, shorten heating time, and improve process uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order for those skilled in the art to better understand the technical solution of the present invention, the heating furnace body and semiconductor equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

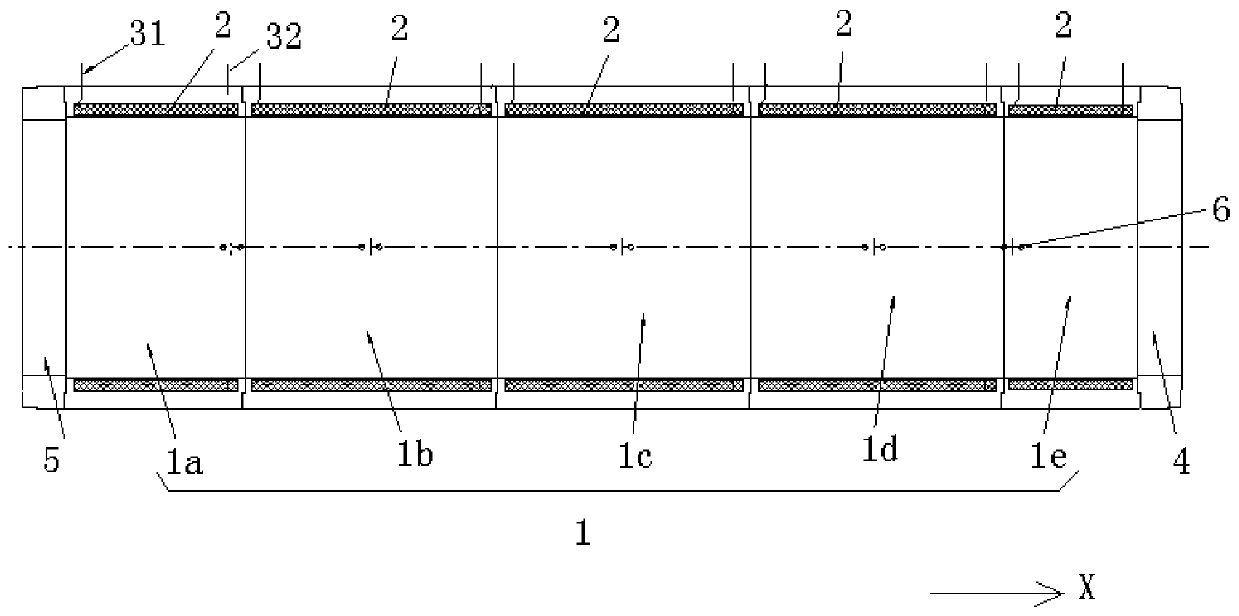

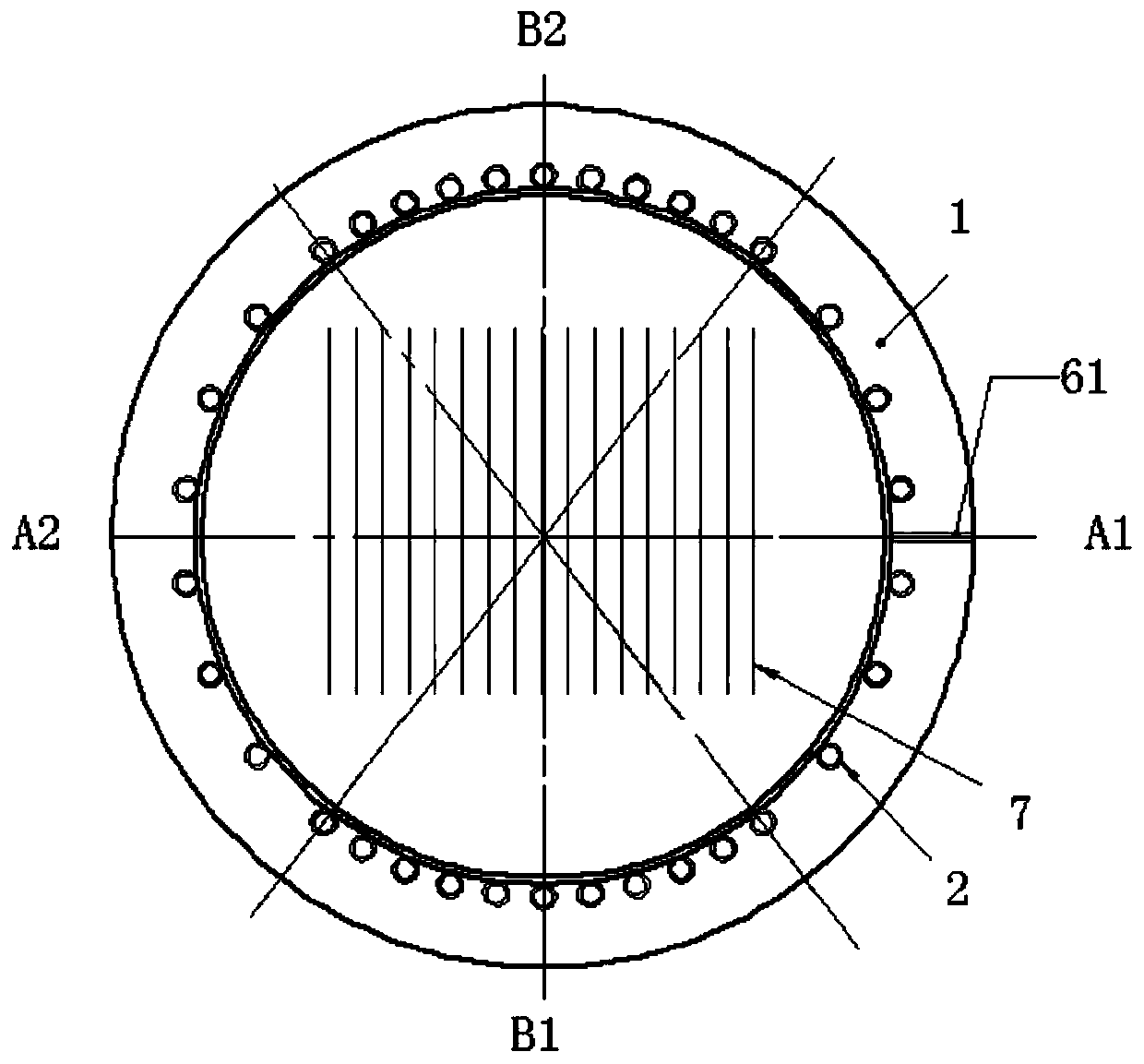

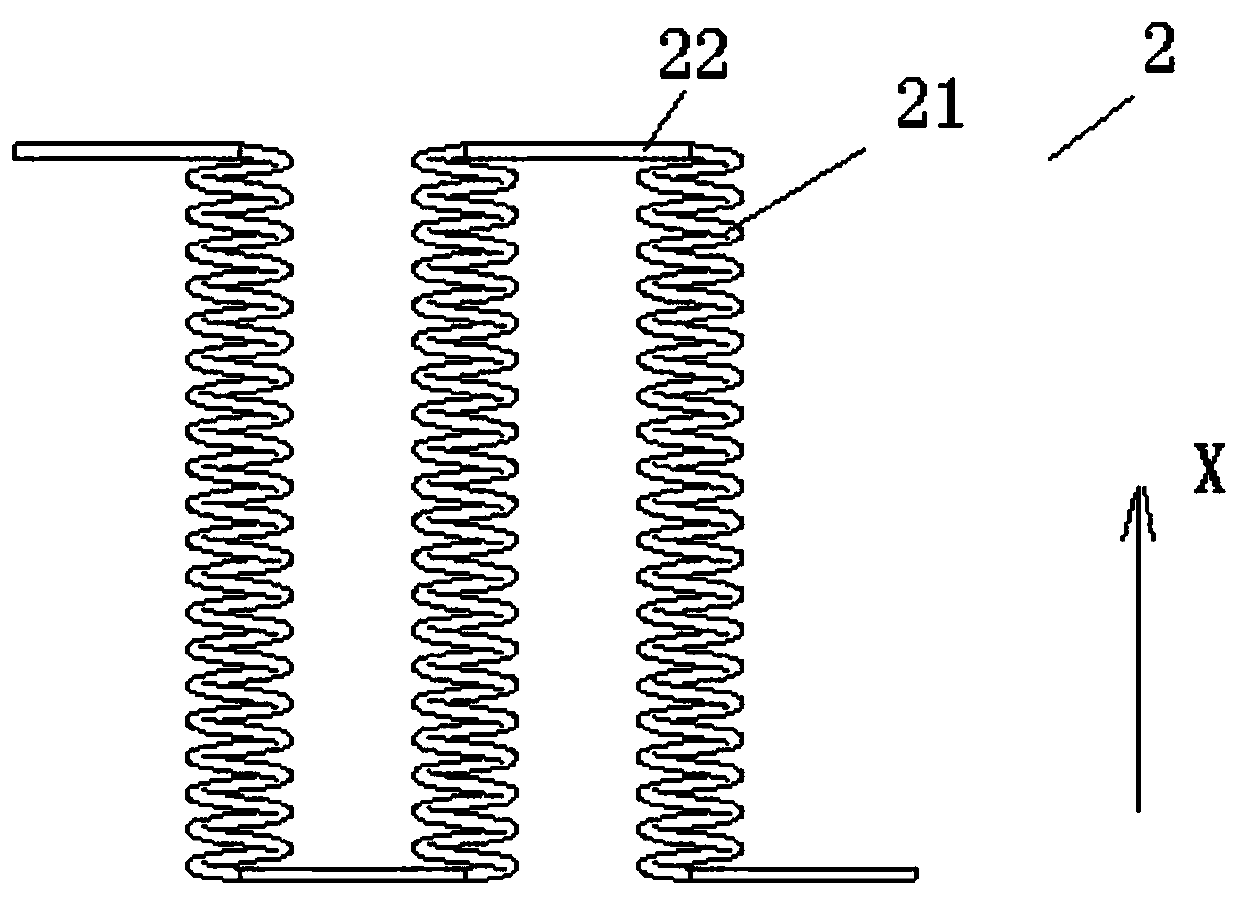

[0039] Please also refer to Figure 1 to Figure 6 , the heating furnace body provided by the embodiment of the present invention includes a plurality of annular heat insulating bodies 1 and a plurality of heating structures 2, wherein the annular insulating body 1 includes a plurality of annular split bodies, and along its axial direction (that is, figure 1 in the X direction) are sequentially connected to form a continuous ring, for example, figure 1 Five ring splits (1a-1e) are shown. The number of heating structures 2 is the same as that of the annular split bodies, and each heating structure 2 is arranged on the inner side of each annular split body in a one-to-one correspondence.

[0040] Opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com