Gas sealing device for continuous carbonization furnace

A carbonization furnace and gas sealing technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of oxidation, affecting the performance of mesophase pitch-based carbon fibers, and the high cost of carbon fibers, and achieve the effect of avoiding eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

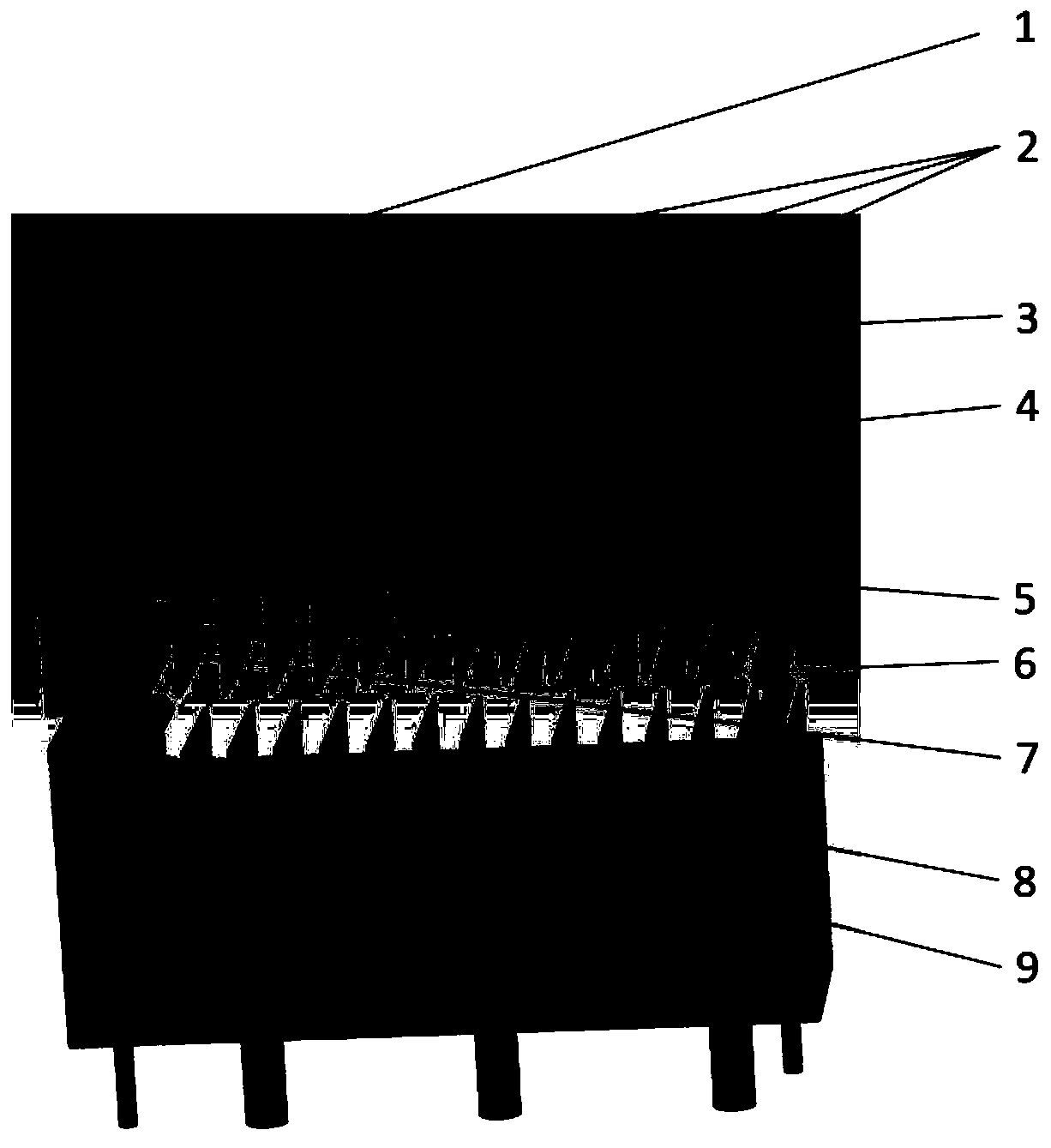

[0013] Such as figure 1 As shown, a gas seal structure of a continuous carbonization furnace, including a front inlet pipe 1, a middle inlet pipe 2, a rear inlet pipe 3, a gas seal chamber 4, a gas distribution plate 5, a furnace port 9, and a material outlet 6 , insulation interlayer 7 and air-tight partition 8. A gas sealing device for a continuous carbonization furnace. The gas sealing device is divided into two parts, which are symmetrical up and down. The middle of the two parts is the material channel from the furnace port 9 to the material outlet 6, and the upper end from the furnace port 9 to the material outlet 6 is arranged in sequence. The front air intake pipe 1, the middle air intake pipe 2 and the rear air intake pipe 3 have the front air outlet pipe, the middle air outlet pipe and the rear air outlet pipe in turn at the lower end. The front air inlet pipe 1 is equipped with a branch pipe, which is located in the insulation interlayer 7. The insulation interlaye...

Embodiment 2

[0016] A gas seal structure of a continuous carbonization furnace, comprising a front intake pipe 1, a middle intake pipe 2, a rear intake pipe 3, a gas seal chamber 4, a gas distribution plate 5, a furnace port 9, a material outlet 6, and an insulating interlayer 7 and air-tight partition 8. It is characterized in that: the whole air seal is an open through type, the furnace port 9 is connected with the inside of the carbonization furnace, and the material outlet 6 is connected with the outside; the opening can be 10cm. The front inlet pipe controls the position and size of the air curtain through the size, arrangement and angle of the air holes. The diameter of the air holes is 3mm, the interval between adjacent air holes is 3mm, and the angle between the direction of the air holes and the vertical direction is 30°; The branch pipe of the inlet pipe is accompanied by auxiliary heating in the insulation interlayer, and the heating temperature is 600ºC. The central air pipe f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com