Construction method for curing concrete in winter by all-automatic electric steam generator

A technology of electric heating steam and concrete, which is applied in basic structure engineering, architecture, building construction, etc., to achieve the effects of convenient movement, high social benefits, and high maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

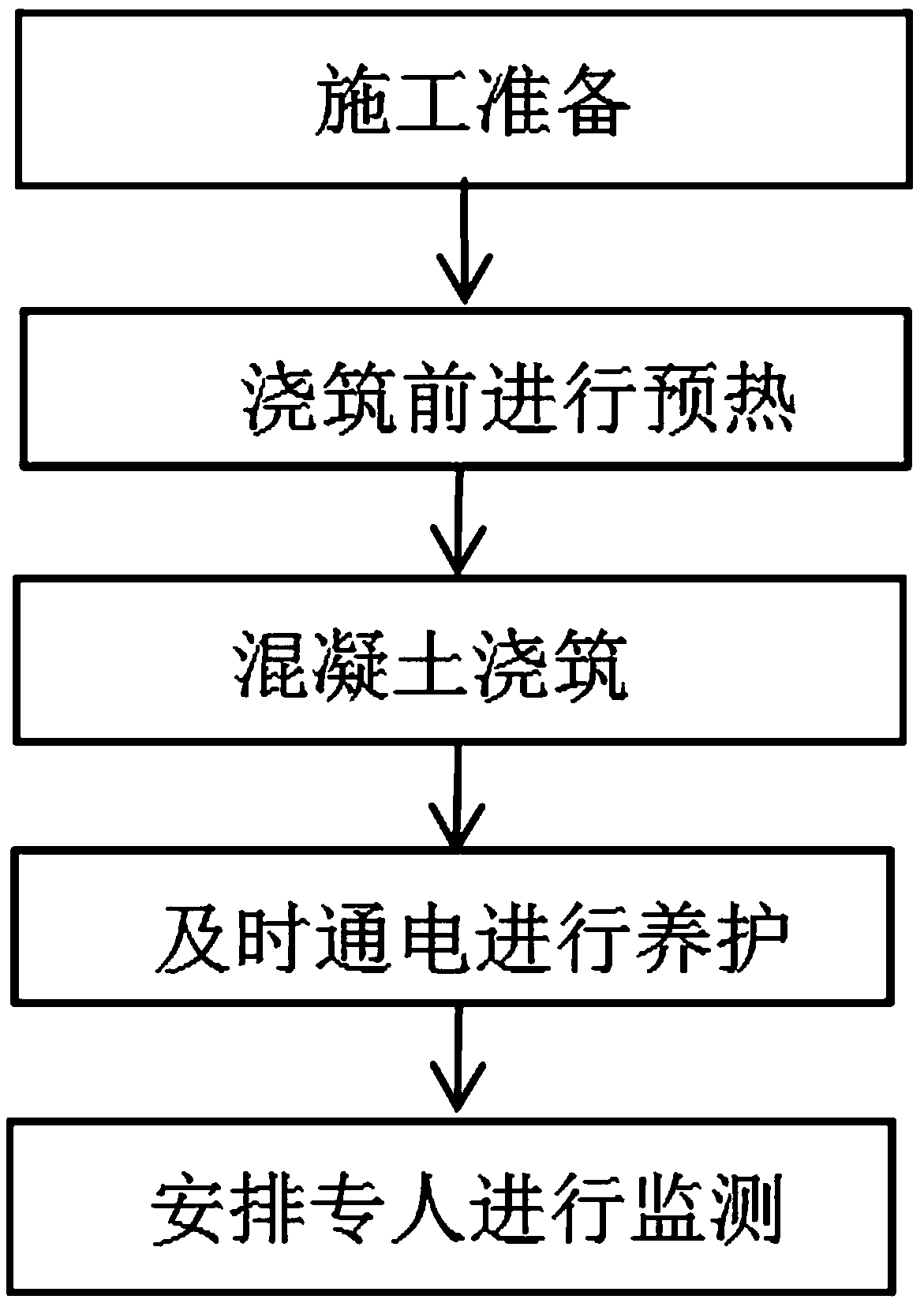

[0031] The construction process flow chart and key points of operation of the present invention are described in detail.

[0032] Operation points:

[0033] Construction preparation:

[0034] 1. Install the greenhouse: the size of the greenhouse depends on the volume of the curing concrete, and scaffolding is used to build the skeleton and reinforce it. Use plastic sheets and tarpaulins for covering and reinforcement (use plastic sheets on the inside and tarpaulins on the outside), so that a closed space is formed inside the tarpaulin, and maintenance is carried out in the closed space, and the liquefied water and hot steam will not be lost.

[0035] 2. Distribution of steam pipes in the greenhouse: The curing effect directly depends on the distribution of steam pipes in the greenhouse, and the steam pipes are laid vertically in the air. It can effectively make the steam circulate in the closed space, so as to quickly increase the temperature in the space. The steam pipe is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com