Thrust vector control system and method based on plasma synthetic jet exciter

A thrust vector control and plasma technology, which is applied in aircraft control, flight direction control, transportation and packaging, etc., can solve the problems of increasing the complexity of the device and unfavorable maintenance, and achieve the effects of simple structure, stable operation and fast response frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

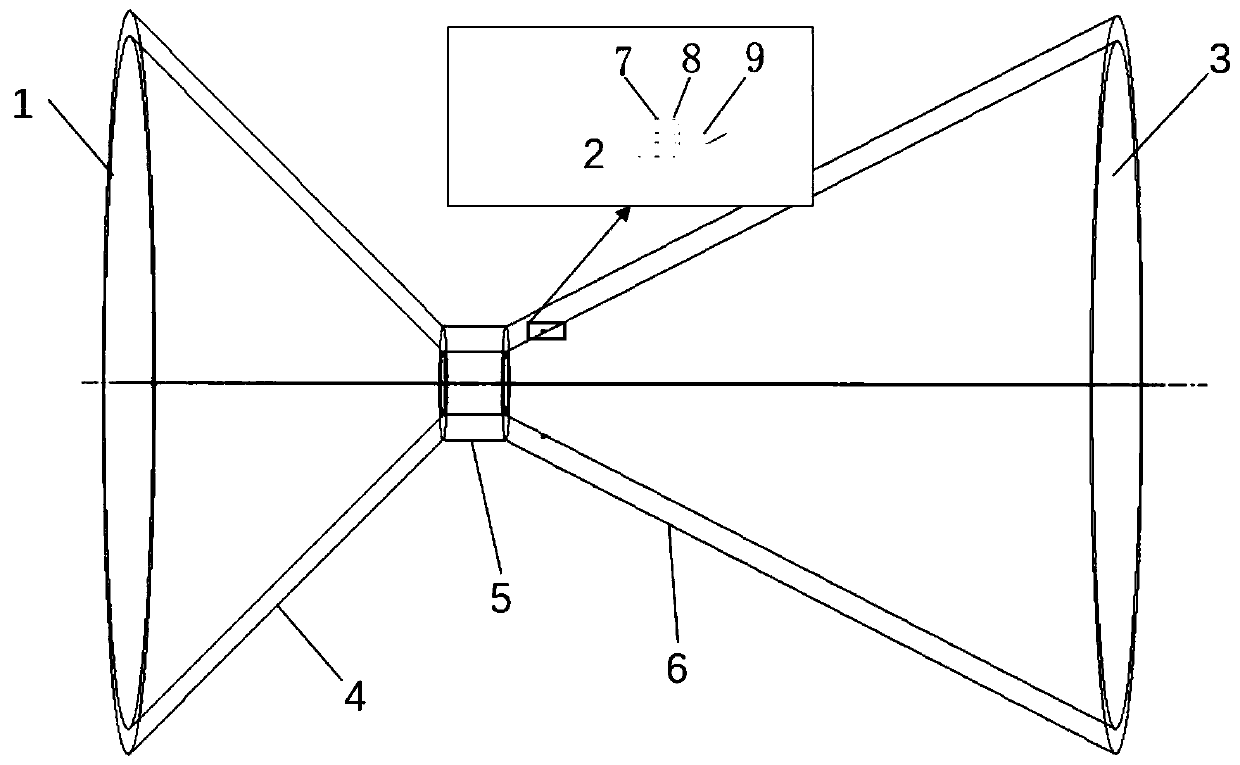

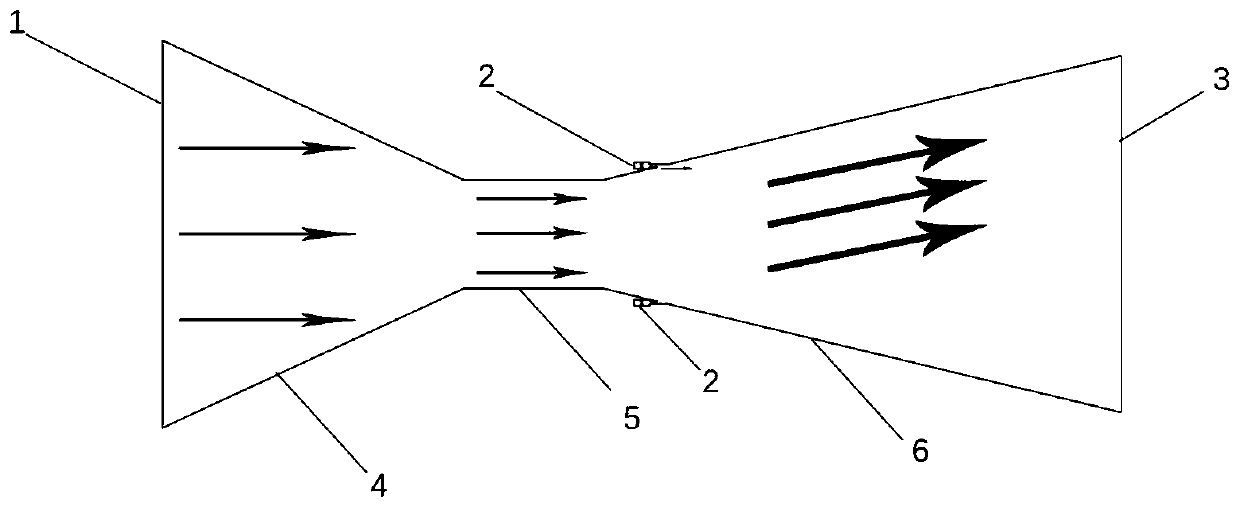

[0024] A thrust vector control system based on a plasma synthetic jet actuator, comprising a nozzle 1 and a plurality of two-electrode plasma jet actuators 2 arranged between the inner and outer walls of the expansion section 6 of the nozzle 1, the two-electrode plasma Jet exciter 2 comprises two electrodes 7, exciter cavity 8, power supply and throat nozzle 9, and described two electrodes 7 are arranged in exciter cavity 8, and described power supply is connected with two electrodes 7, so The outlet of the exciter cavity 8 communicates with the inner wall of the expansion section 6 through the throat nozzle 9 .

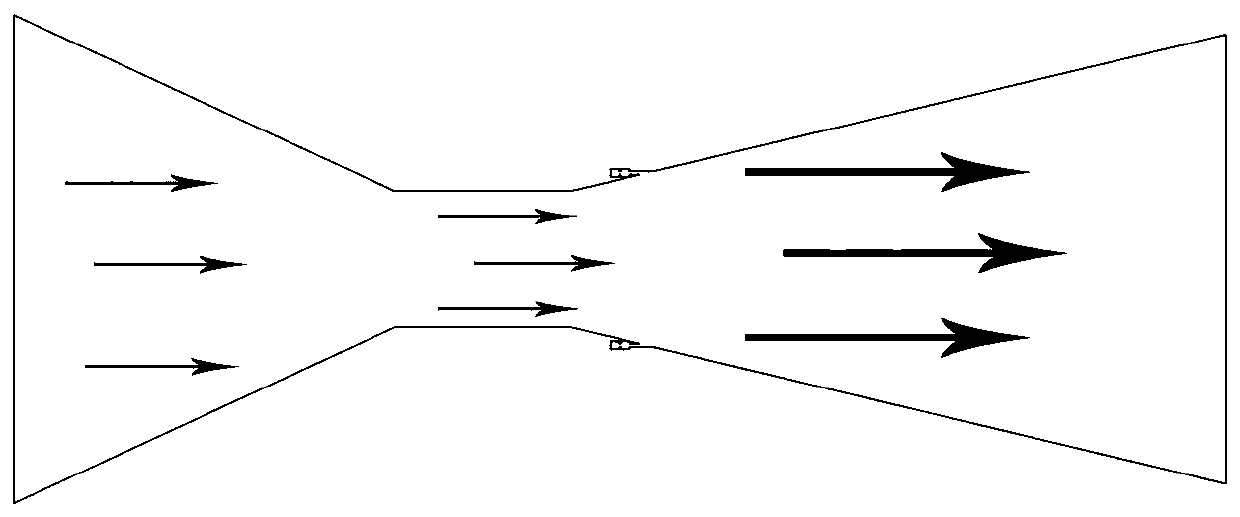

[0025] Further, the nozzle 1 is a Laval nozzle, including a constriction section 4 , a throat transition section 5 and an expansion section 6 , and a plurality of two-electrode plasma jet actuators 2 are arranged symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com