Lossless anti-blocking drainer for compressed gas condensate

A technology for compressing gas and drains, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems affecting reliability, waste of manpower, limited water storage in drains, etc., to reduce the number of actions, reduce Maintenance cost, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further clarified below in conjunction with specific drawings.

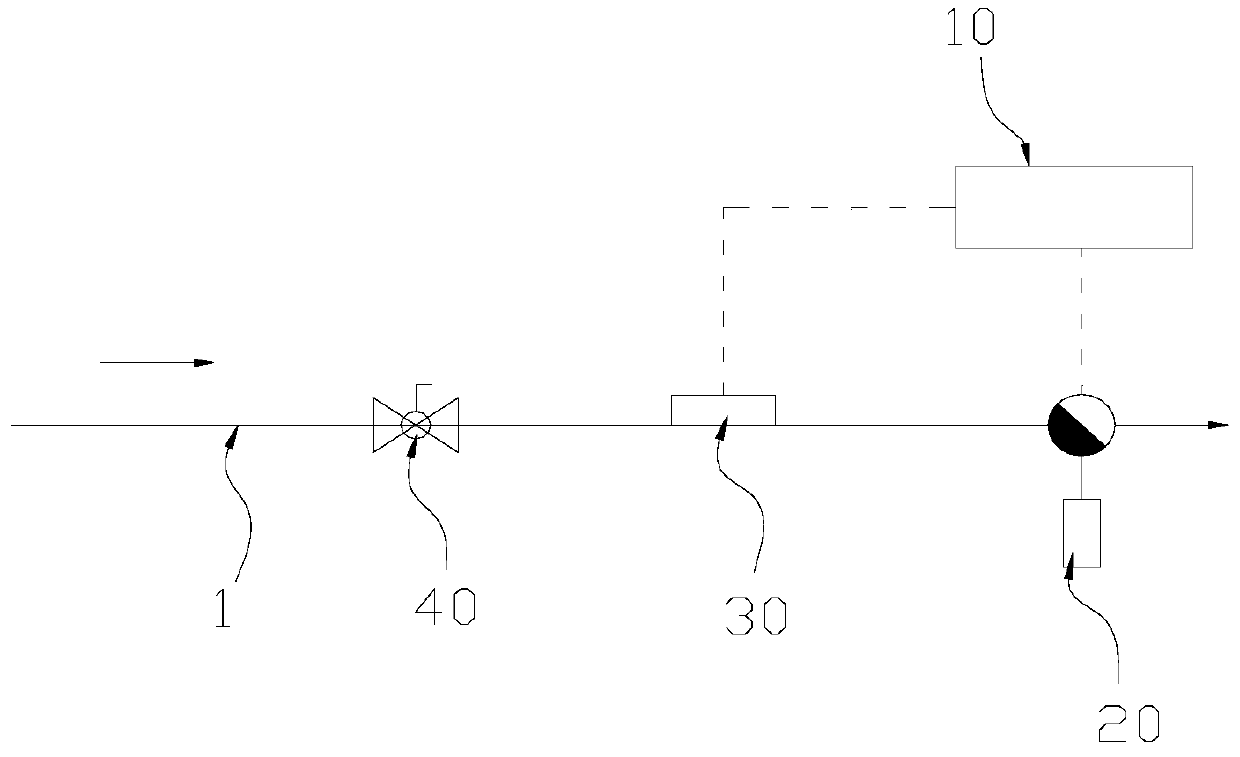

[0029] combine figure 1 As shown, the present invention provides a non-destructive anti-blocking drain for compressed gas condensate, which is used for drainage of gas-liquid separators. The non-destructive anti-blocking drain includes a controller 10, an electromagnetic drain valve 20 and a non-contact liquid level Sensor 30; the electromagnetic drain valve 20 is connected to the drain pipe 1 of the gas-liquid separator for controlling drainage; the non-contact liquid level sensor 30 is arranged on the drain pipe 1 for monitoring whether there is water;

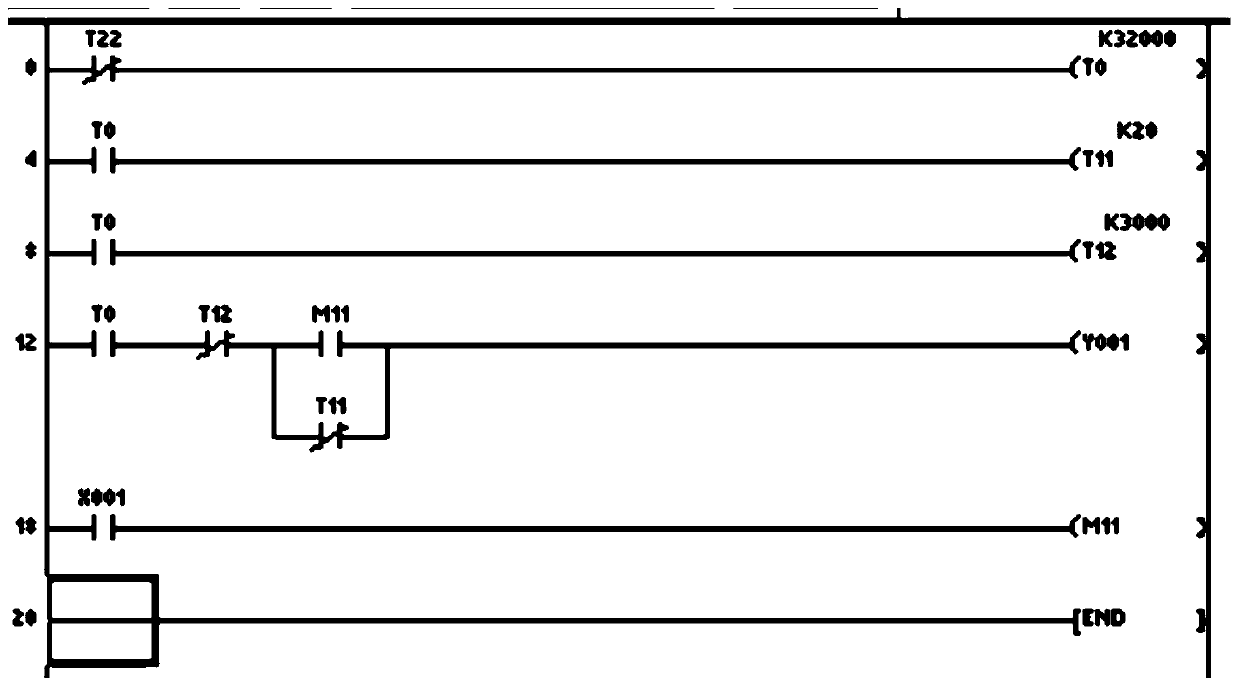

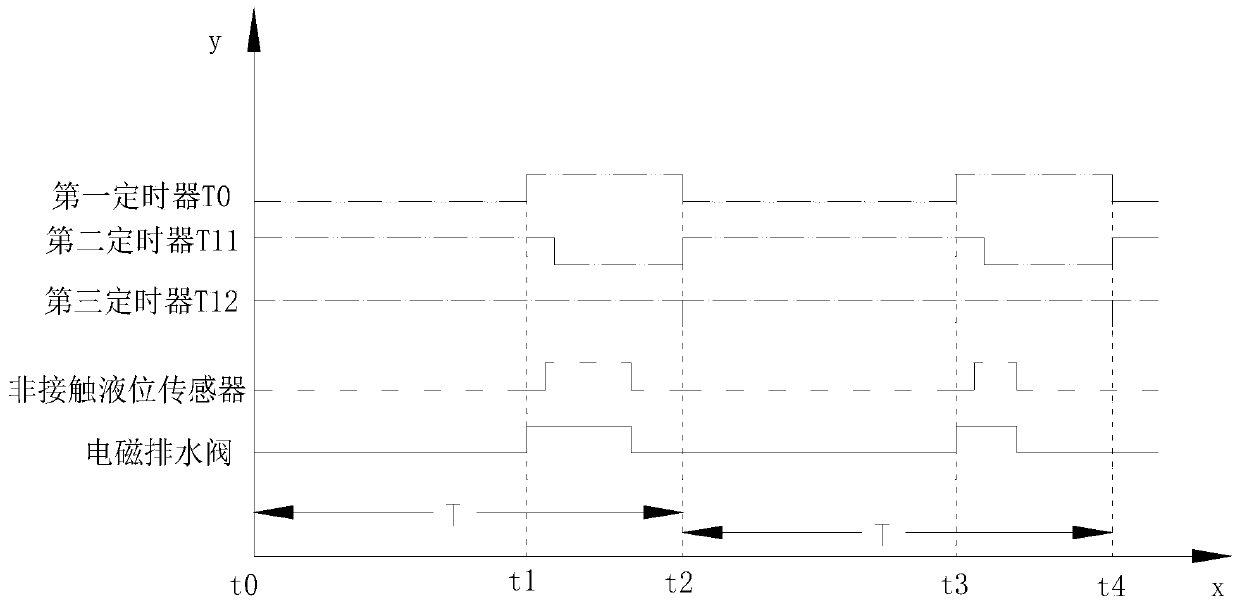

[0030] Wherein, the controller 10 is equipped with a first timer T0, a second timer T11 and a third timer T12; the first timer T0 is used to set the working cycle of the electromagnetic drain valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com