Heat exchanger applied to gas water heater

A gas-fired water heater and heat exchanger technology, applied in heat exchange equipment, water heaters, fluid heaters, etc., can solve the problems of rising shell surface temperature, occupying space, and high heat loss, so as to improve the heat exchange rate, The effect of reducing the occupied space and reducing the surface temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

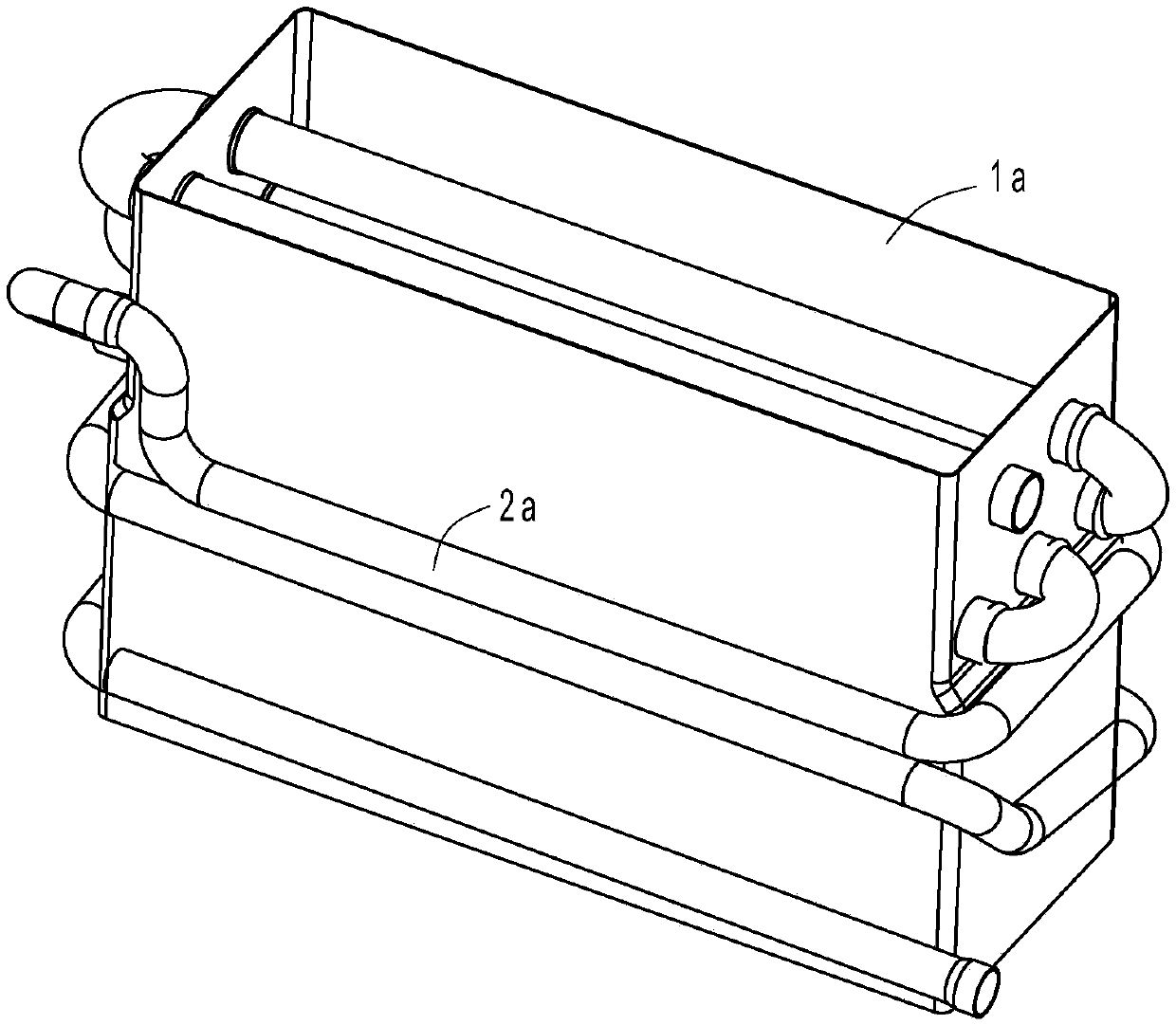

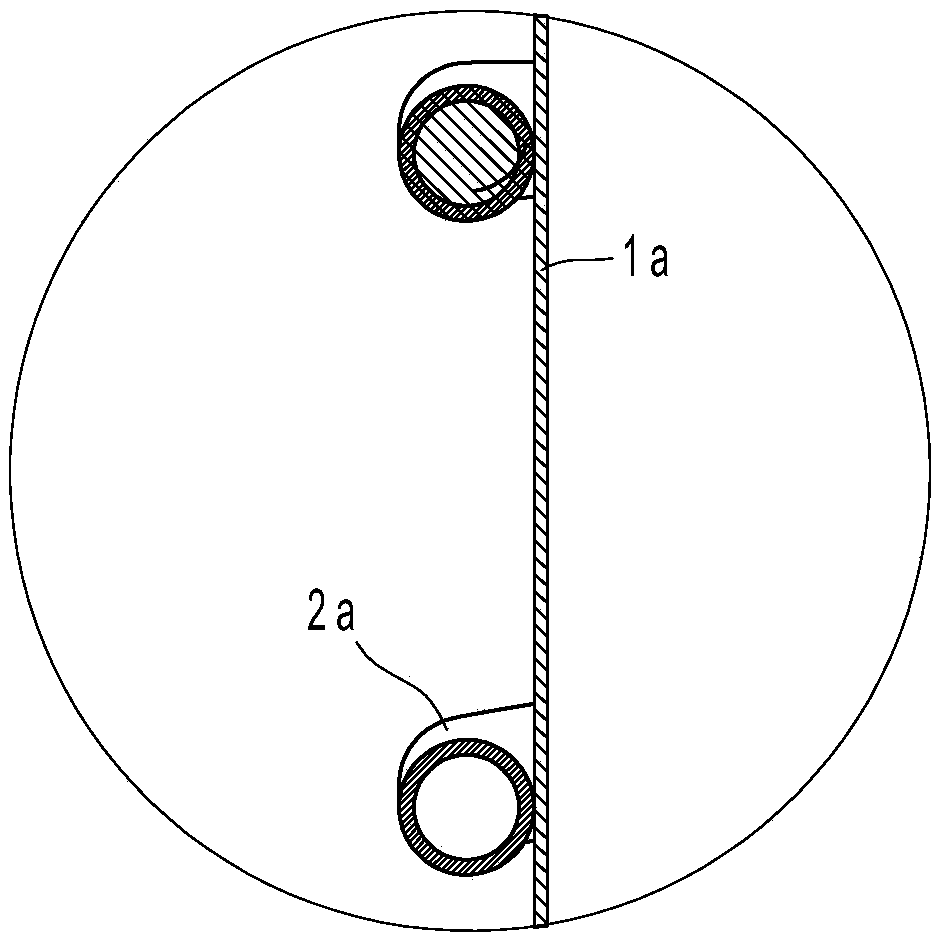

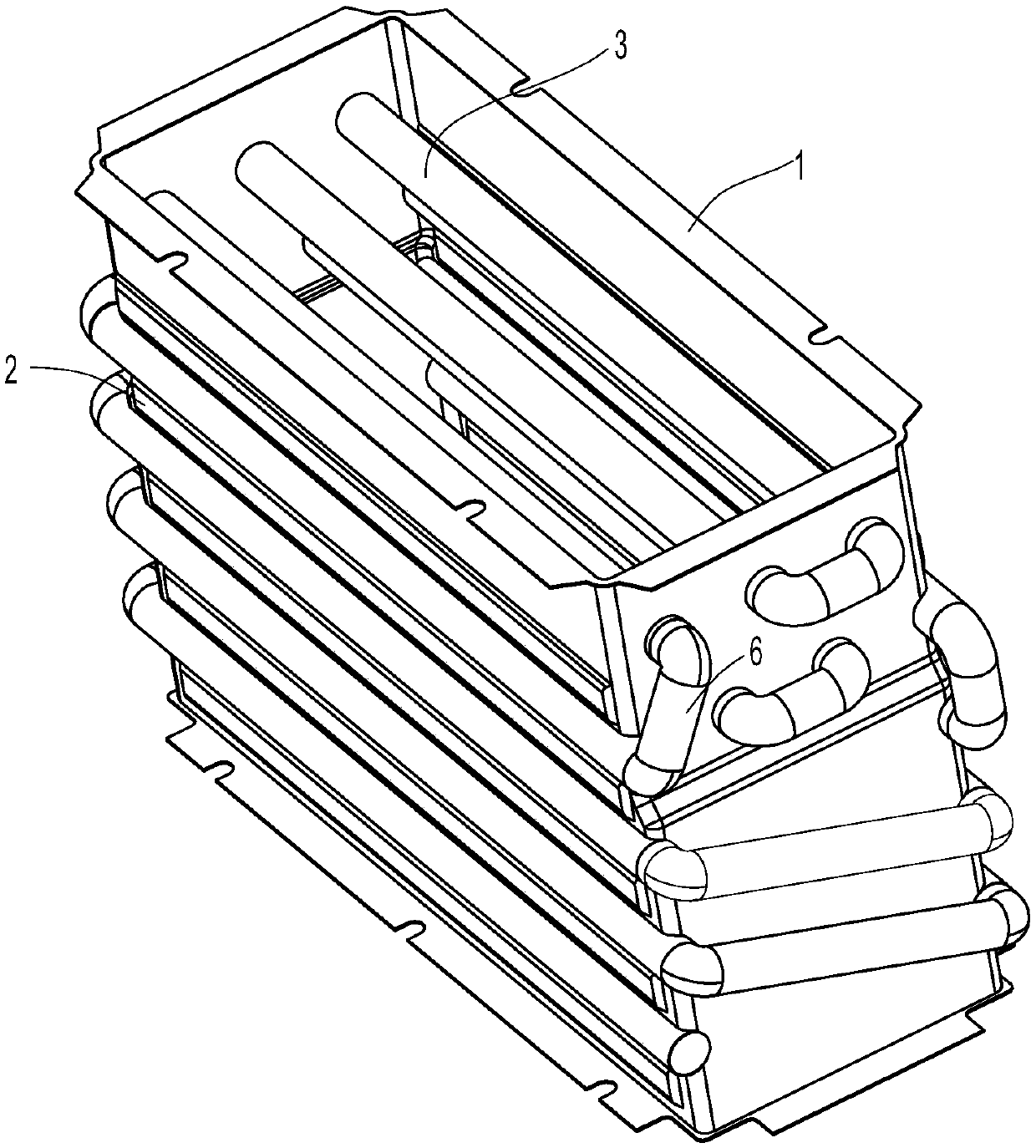

[0016] Such as image 3 , Figure 4 with Figure 5 As shown, the heat exchanger in this embodiment is applied to a gas water heater, and specifically includes a shell 1, a coil tube arranged on the outer wall of the shell 1, and an inner tube arranged in the shell. The outer wall of the shell 1 has a strip shape The first groove 11, the outer wall of the housing 1 is provided with a bonding plate 2 that is closely attached to it, and a strip-shaped second groove 21 is formed on the bonding plate 2, and the second groove 21 is butted with the first groove 11 Join together to form a water pipe channel 4.

[0017] The first grooves 11 are multiple and arranged up and down at intervals. Correspondingly, the second grooves 21 are also multiple and arranged up and down at intervals. A strip-shaped third groove 22 is formed between the first grooves 11, and corre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap