Industrial lens

A lens, industrial technology, applied in the field of optical lenses, can solve the problems of aberration, distortion, image black, etc., achieve high image quality, reduce processing and assembly costs, and widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

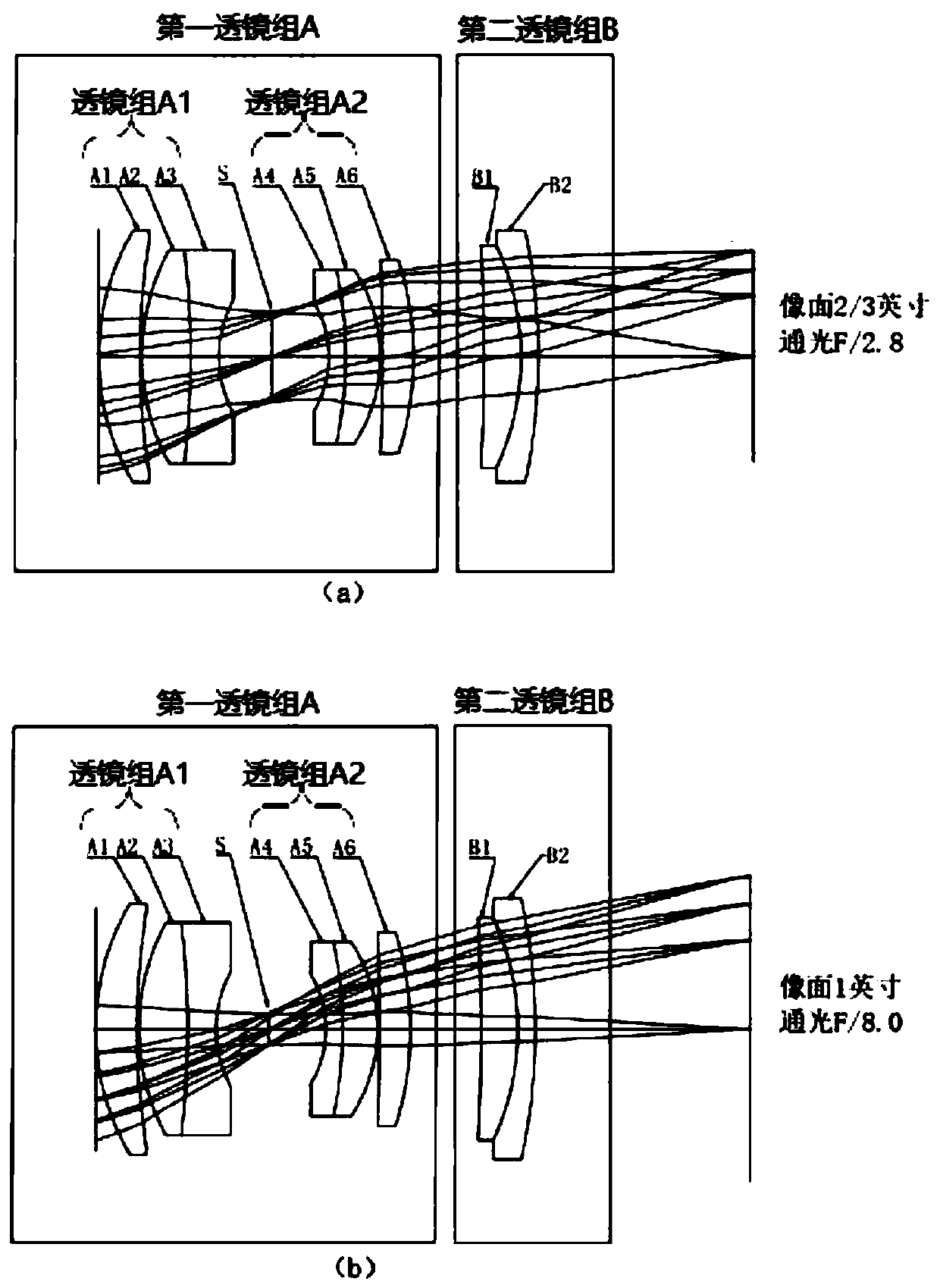

[0043] In this embodiment, the first lens group A is sequentially provided with a lens group A1, a variable diaphragm S and a lens group A2 along the light incident direction;

[0044] Wherein, the lens group A1 is provided with a meniscus positive lens A1, a biconvex positive lens A2 and a biconcave negative lens A3 sequentially along the light incident direction, wherein the meniscus positive lens A2 and the meniscus negative lens A3 form a doublet lens.

[0045] The lens group A2 is sequentially provided with a meniscus negative lens A4, a meniscus positive lens A5 and a plano-convex positive lens A6 along the light incident direction, wherein the meniscus negative lens A4 and the meniscus positive lens A5 form a doublet lens.

[0046] The second lens group B is provided with a biconvex positive lens B1 and a meniscus negative lens B2, which are cemented to form a doublet lens.

[0047] Combined focal length f of the first lens group A A is 25.1mm, the combined focal lengt...

Embodiment 2

[0059] In this embodiment, the first lens group A is sequentially provided with a lens group A1, a variable diaphragm S and a lens group A2 along the light incident direction;

[0060] Wherein, the lens group A1 is provided with a meniscus positive lens A1, a biconvex positive lens A2 and a biconcave negative lens A3 sequentially along the light incident direction, wherein the meniscus positive lens A2 and the meniscus negative lens A3 form a doublet lens.

[0061] The lens group A2 is sequentially provided with a meniscus negative lens A4, a meniscus positive lens A5 and a plano-convex positive lens A6 along the light incident direction, wherein the meniscus negative lens A4 and the meniscus positive lens A5 form a doublet lens.

[0062] The second lens group B is provided with a biconvex positive lens B1 and a meniscus negative lens B2, which are cemented to form a doublet lens.

[0063] Combined focal length f of the first lens group A A is 24.1mm, the combined focal lengt...

Embodiment 3

[0070] In this embodiment, the first lens group A is sequentially provided with a lens group A1, a variable diaphragm S and a lens group A2 along the light incident direction;

[0071] Wherein, the lens group A1 is provided with a meniscus positive lens A1, a biconvex positive lens A2 and a biconcave negative lens A3 sequentially along the light incident direction, wherein the meniscus positive lens A2 and the meniscus negative lens A3 form a doublet lens.

[0072] The lens group A2 is sequentially provided with a meniscus negative lens A4, a meniscus positive lens A5 and a plano-convex positive lens A6 along the light incident direction, wherein the meniscus negative lens A4 and the meniscus positive lens A5 form a doublet lens.

[0073] The second lens group B is provided with a biconvex positive lens B1 and a meniscus negative lens B2, which are cemented to form a doublet lens.

[0074] Combined focal length f of the first lens group A A is 23.0mm, the combined focal lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com