Direct-writing photoetching machine splicing method

A direct-writing, lithography machine technology, applied in semiconductor lithography machine graphics image processing, graphics splicing, and computer graphics development, can solve problems such as unsatisfactory customers, slow production capacity, etc., to improve splicing accuracy and reduce self-precision needs, the effect of improving graphics quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

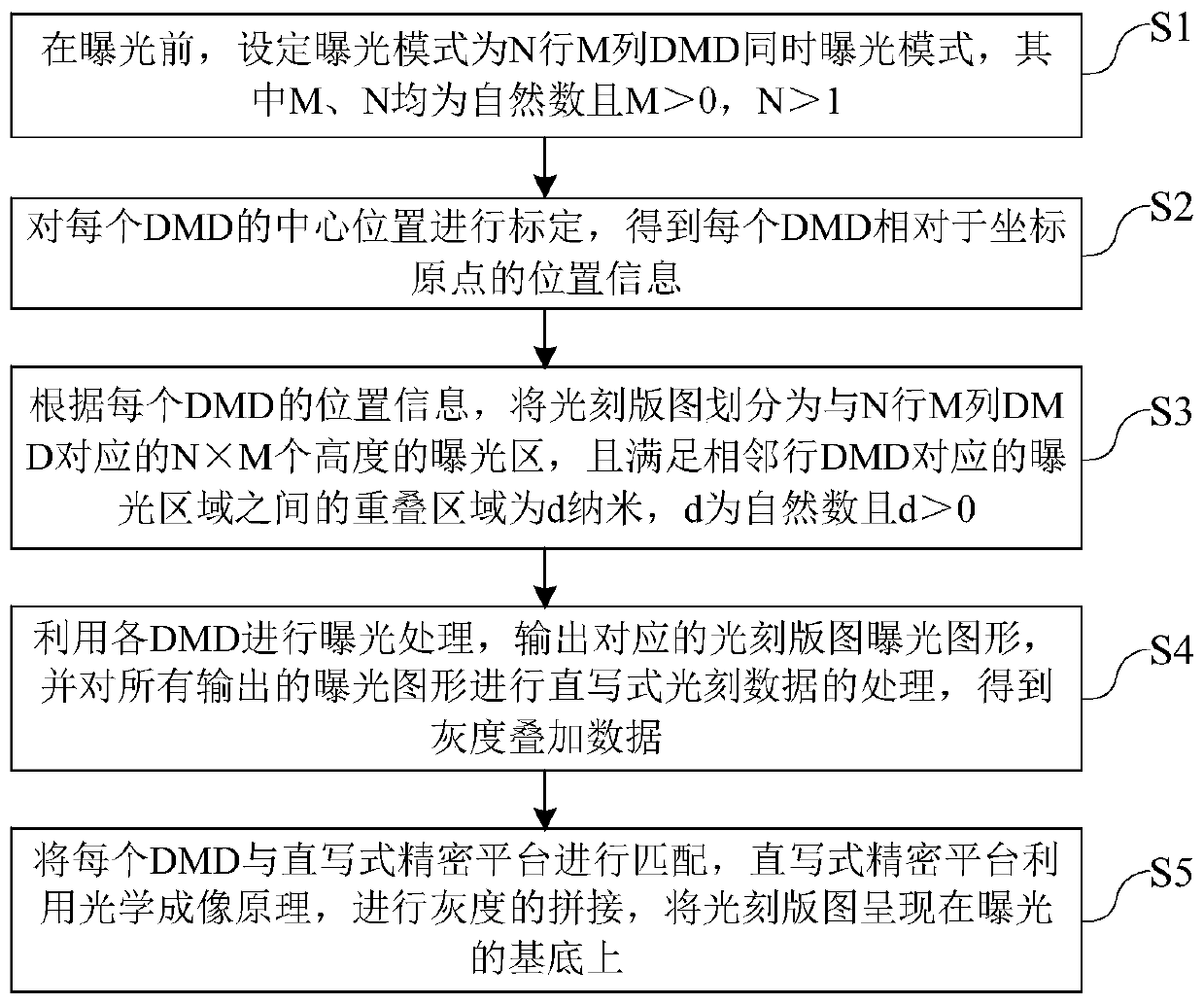

[0031] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a splicing method for a direct-writing lithography machine, including the following steps S1-S5:

[0032] S1. Before exposure, set the exposure mode to N rows and M columns DMD simultaneous exposure mode, where M and N are natural numbers and M>0, N>1;

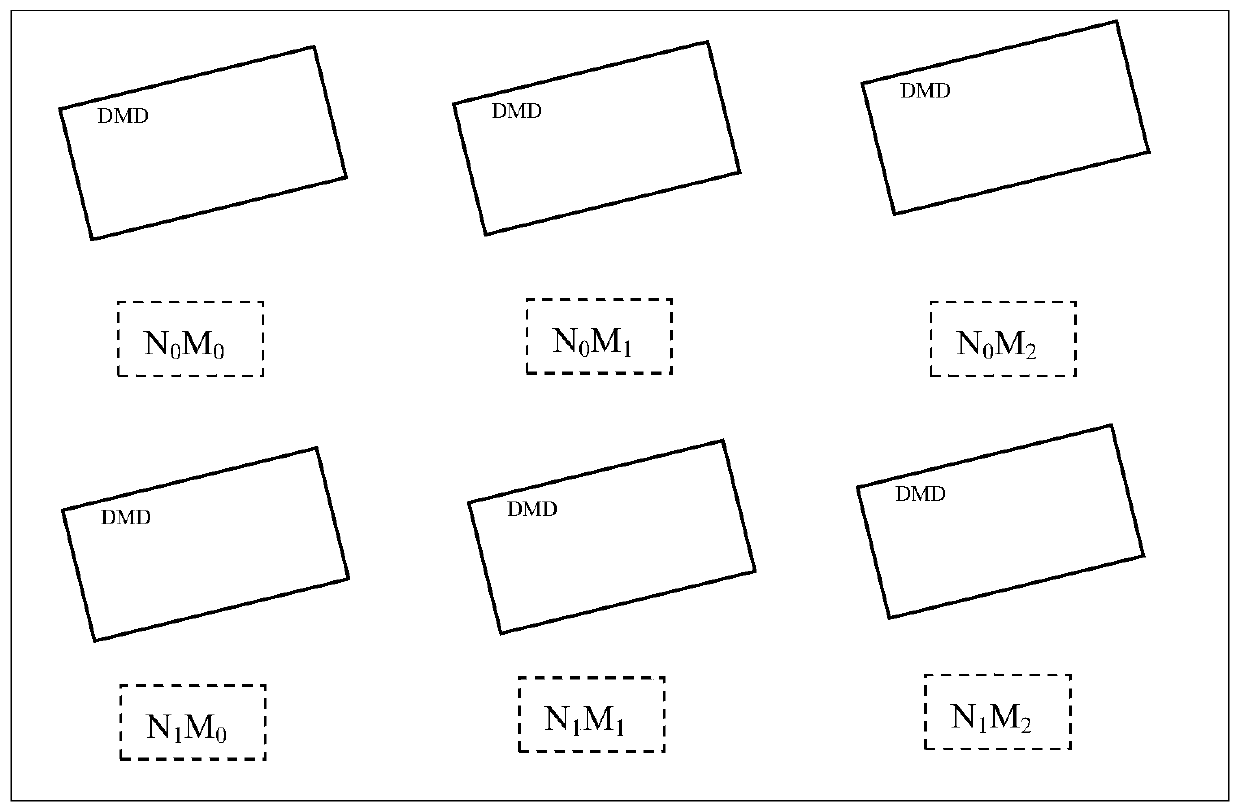

[0033] S2. Calibrate the center position of each DMD to obtain the position information of each DMD relative to the coordinate origin;

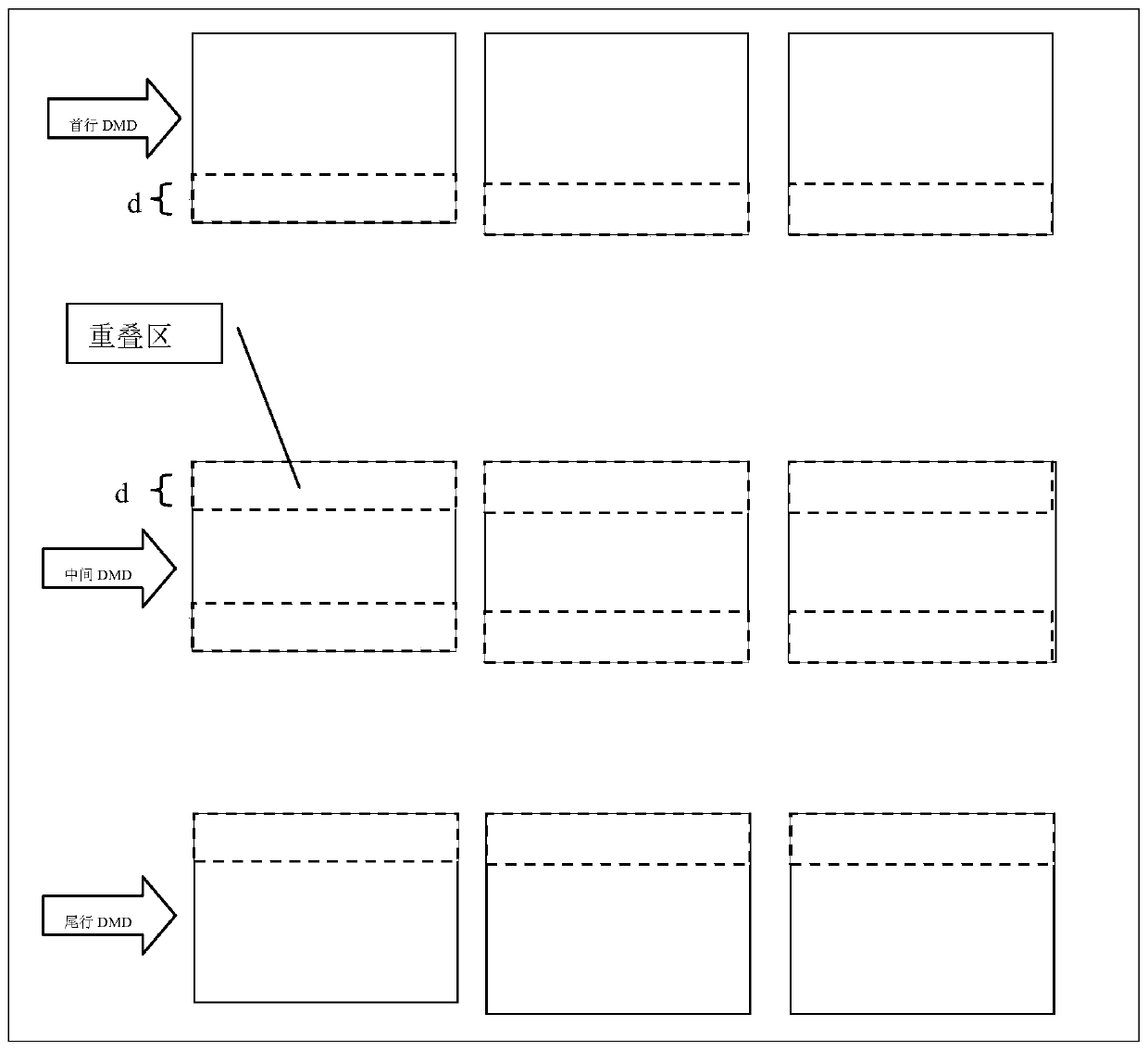

[0034] S3. According to the position information of each DMD, divide the lithography layout into exposure areas of N×M heights corresponding to N rows and M columns of DMDs, and satisfy the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com