Loading control method for dynamic offset directional rotary steering drill tool test bed

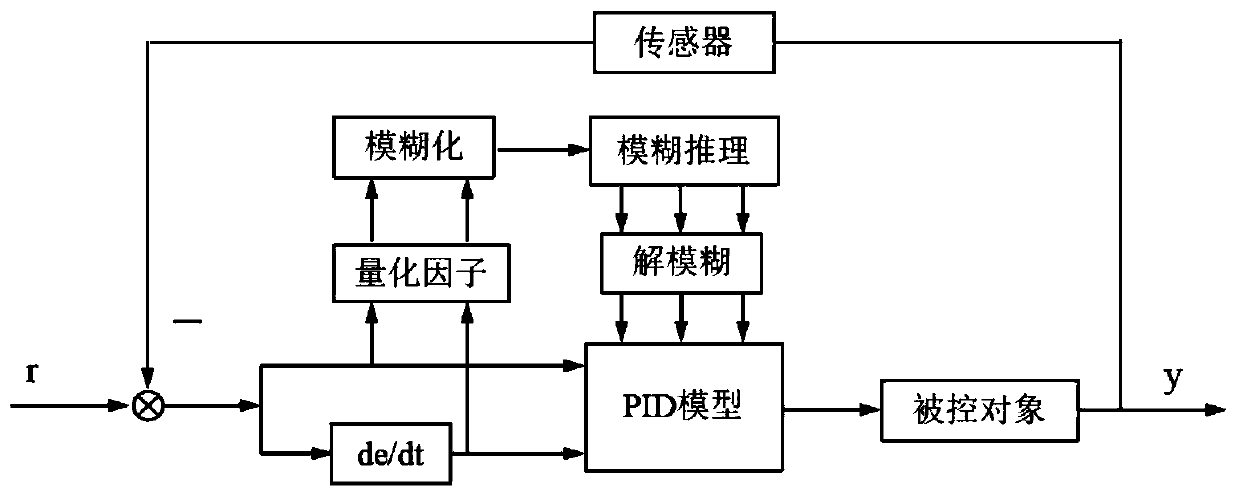

A technology for rotary steerable drilling and tool testing, which is used in directional drilling, reasoning methods, special data processing applications, etc., and can solve problems such as modeling difficulties and mathematical model uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below in conjunction with accompanying drawing.

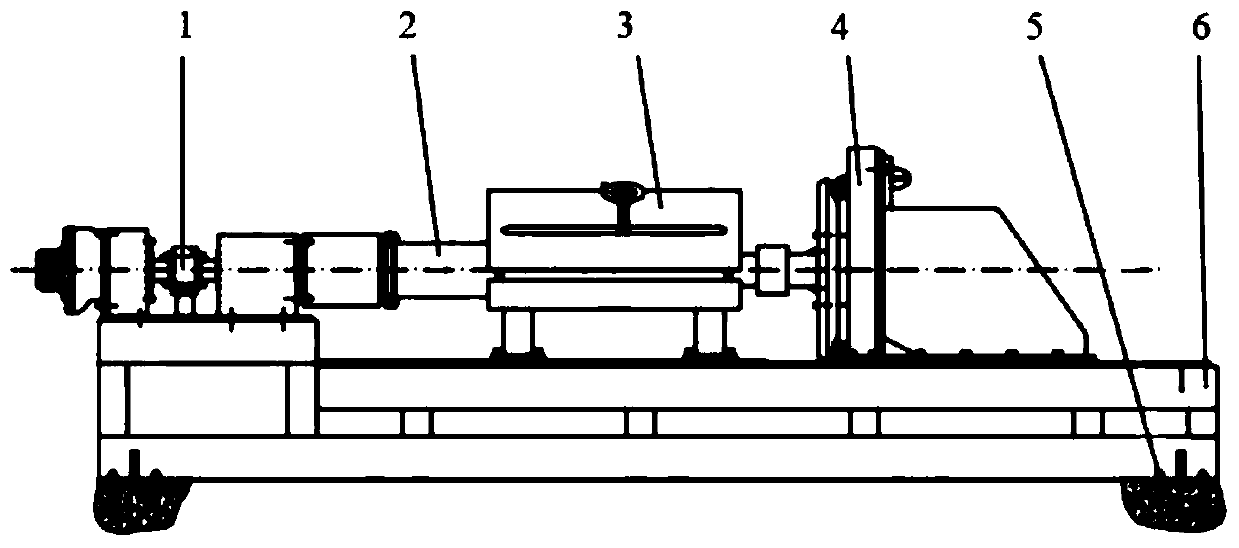

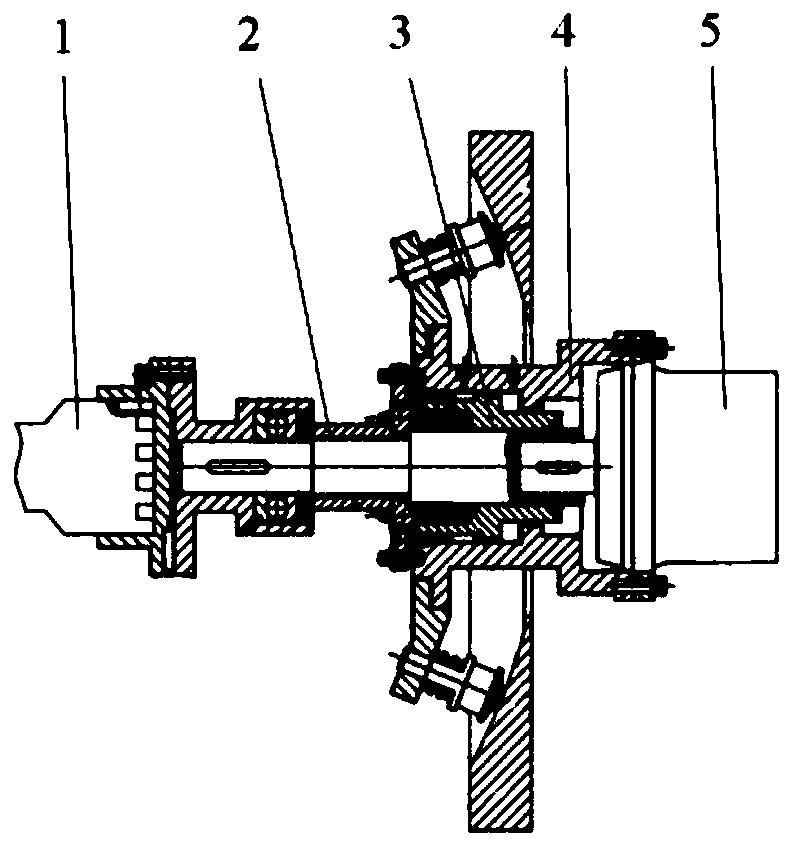

[0047] refer to figure 1 , Patent No. CN107219084A discloses a dynamic pointing rotary steering drilling tool performance test bench, the steering drilling tool test bench includes a rotating device 1, a pointing rotary steering drilling tool 2, a drilling tool clamping device 3, The simulated loading device 4, the expansion bolt 5, and the frame body 6; wherein the structure of the simulated loading device is as follows figure 2 shown. It mainly includes a drill bit 1, an axial pressure sensor 2, an oil cylinder hollow shaft 3, an oil cylinder body 4, and a magnetic powder brake 5. The method for loading control based on the dynamic bias pointing type rotary steerable drilling tool test bed includes the following steps:

[0048] Step 1: Establish the mathematical model of the simulating loading system of the steerable drilling tool test bench

[0049] 1. Establish the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com