Production management and control system and method based on industrial Internet of Things

A technology of industrial internet of things, management and control system, applied in the field of production management and control system based on industrial internet of things, can solve the problems of cumbersome operation, delayed production, unable to continue production, etc., to simplify the process and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0023] The material backup of production-oriented enterprises often sets up a transfer warehouse and a same-day warehouse. The same-day warehouse is used to meet the production needs of the day, and the transfer warehouse is a warehouse for storage and transfer. In order to achieve fast and reliable realization of material distribution request deployment , realize the data allocation request and related request records of the two warehouses based on the industrial Internet of Things, so as to improve the distribution efficiency. The specific principles are as follows:

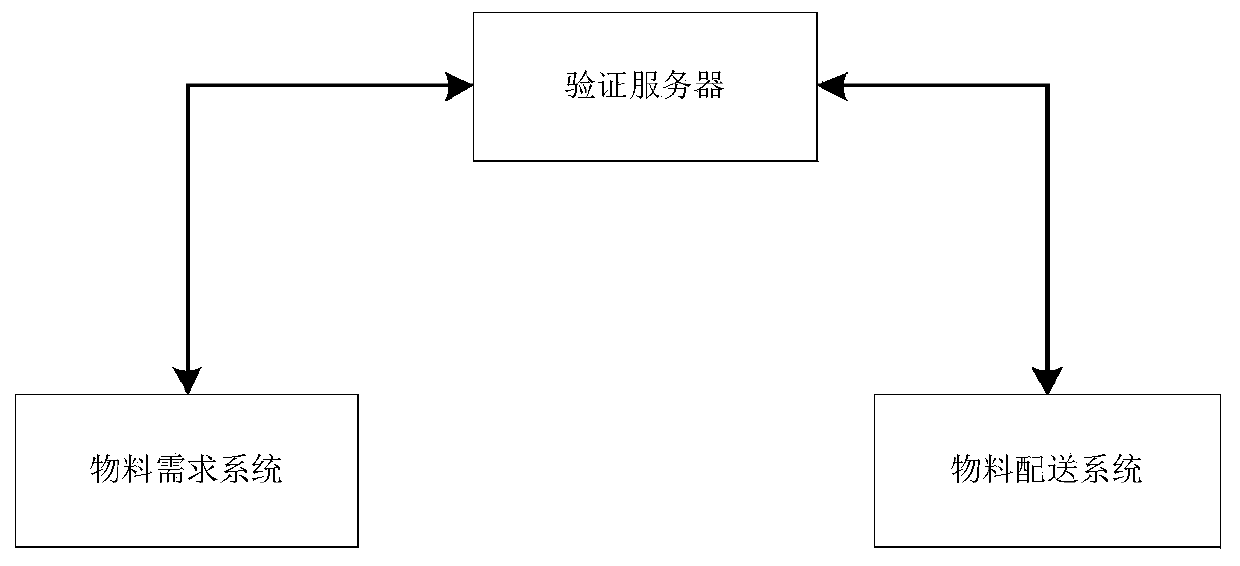

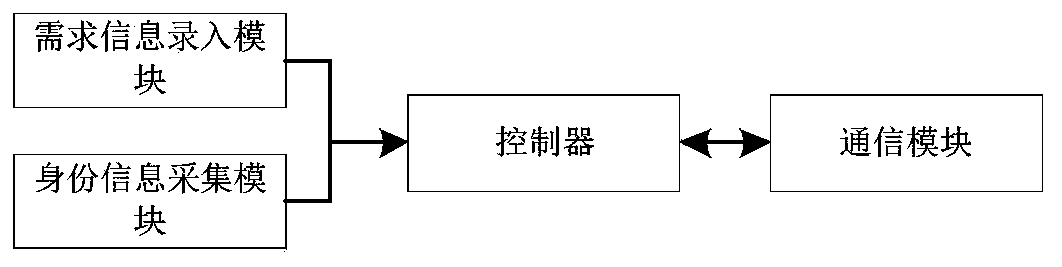

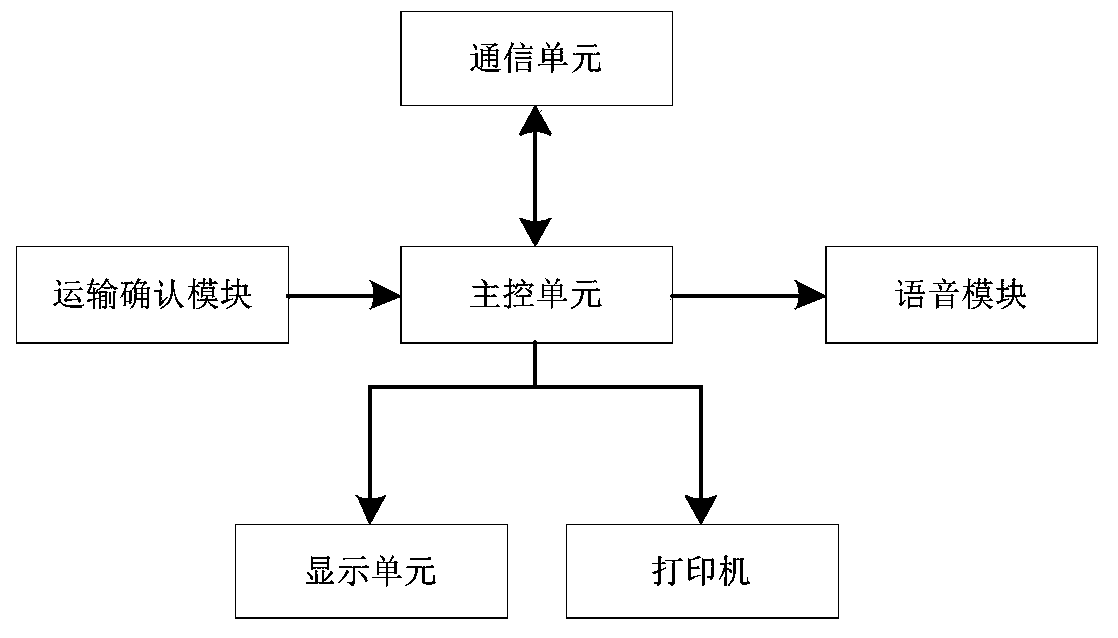

[0024] Such as figure 1 As shown, a production control system based on the Industrial Internet of Things includes a material demand system set in the daily warehouse and a material distribution system set in the transit war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com