Diode clamping hybrid MMC circuit with self-voltage-sharing capability

A diode clamping and self-balancing technology, applied in electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve the problems of large capacitance voltage difference, unfavorable recovery, and high cost. The effect of voltage equalization and device cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

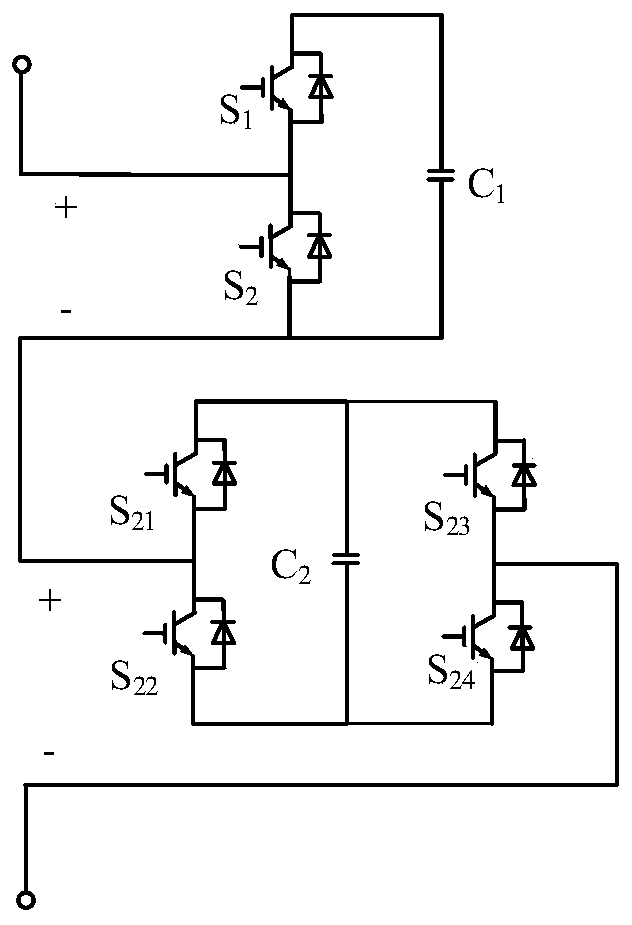

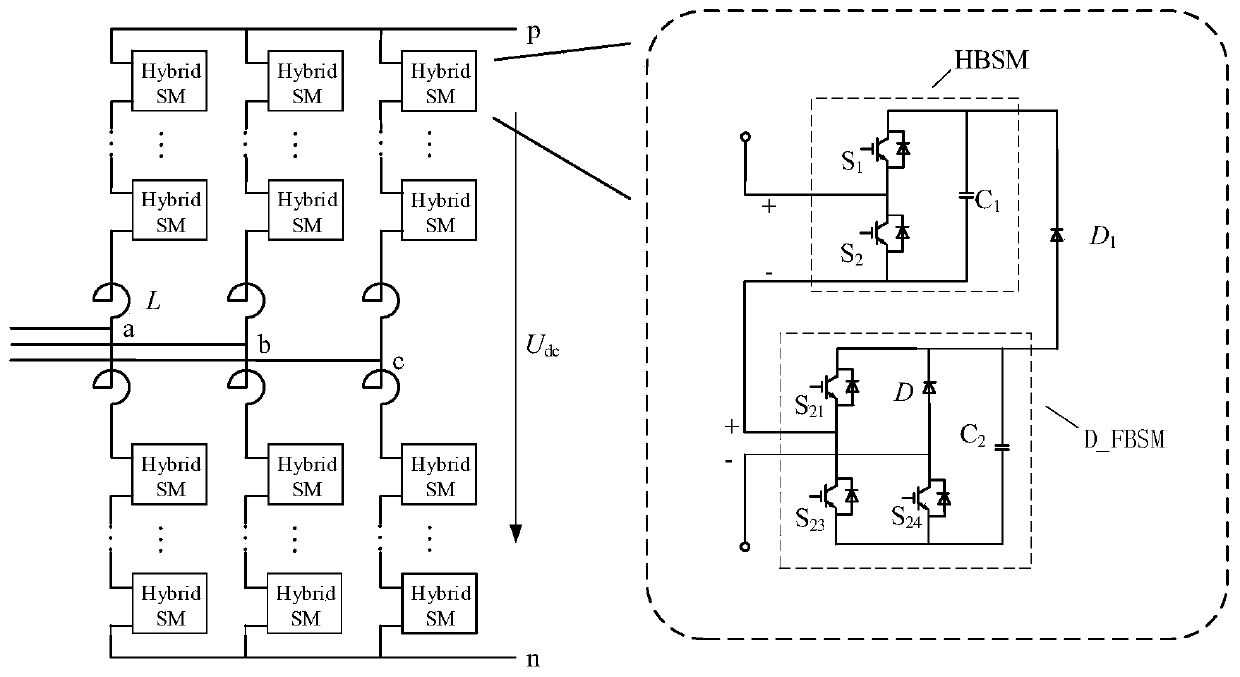

[0023] The present invention proposes a diode-clamp hybrid MMC circuit with self-equalizing capability, such as figure 2 As shown, multiple hybrid sub-modules Hybrid SM are connected in series on the bridge arm of the MMC circuit, and each hybrid sub-module Hybrid SM consists of a half-bridge sub-module HBSM, a full-bridge sub-module D-FBSM and a clamping diode D1 , where the negative pole of the clamping diode D1 is connected to the positive pole of the capacitor C1 of the half-bridge sub-module HBSM, the positive pole of the clamping diode D1 is connected to the positive pole of the capacitor C2 of the full-bridge sub-module D-FBSM, the negative pole of the half-bridge sub-module HBSM and the full-bridge The positive pole of the sub-module D-FBSM is connected.

[0024] The MMC circuit includes three upper bridge arms and three lower bridge arms symmetrically arranged, the upper nodes of the three upper bridge arms are connected, and the lower nodes are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com