Collimating apparatus capable of performing segmented and stepless adjustment on slits

A collimator, stepless technology, applied in the field of collimator, can solve the problems of high processing cost, low dose utilization rate, and non-stepless adjustment of arc-shaped gates, so as to meet the needs of different layer thicknesses and improve dose utilization Ratio, the effect of reducing the seam area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention is described in further detail.

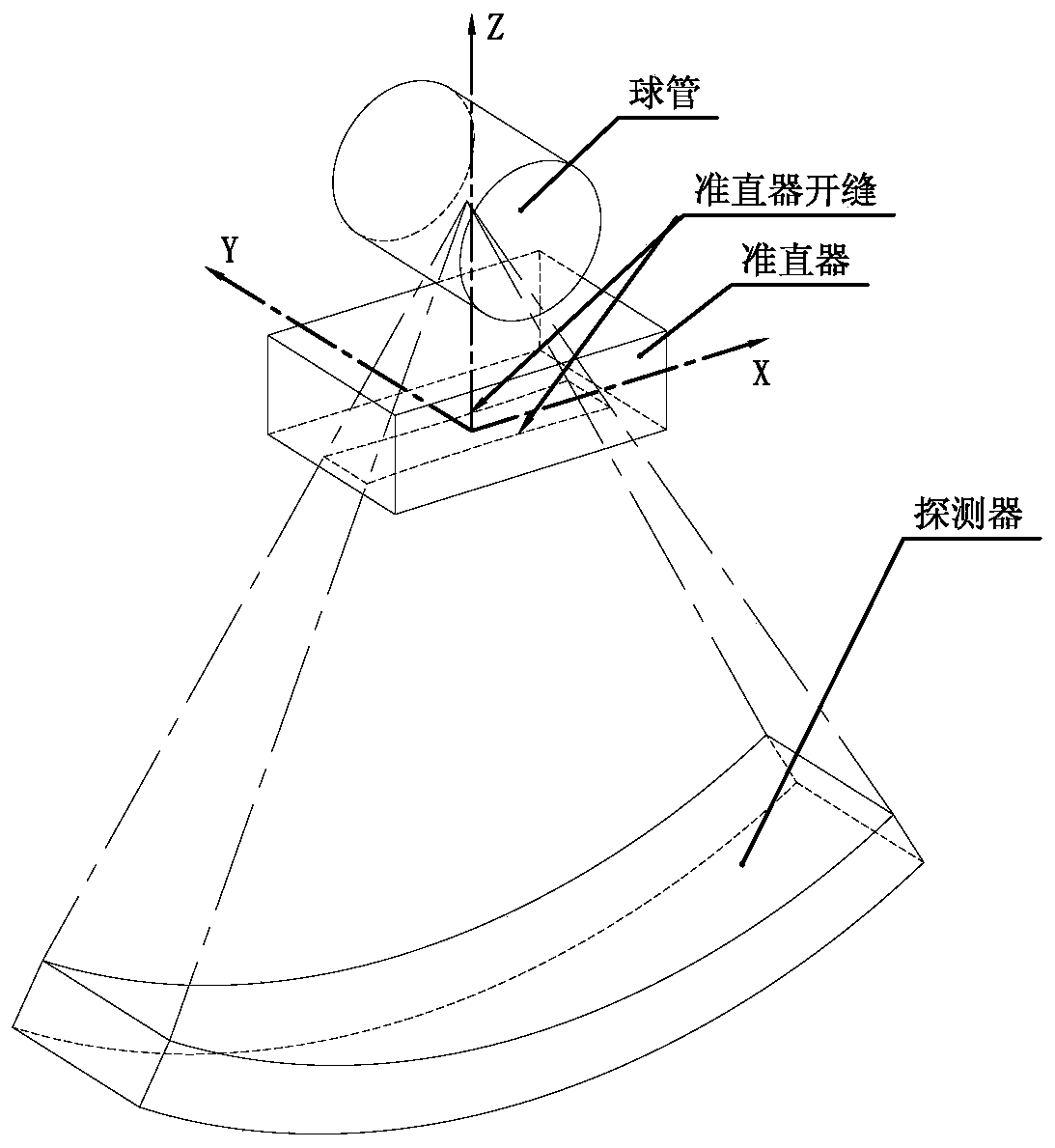

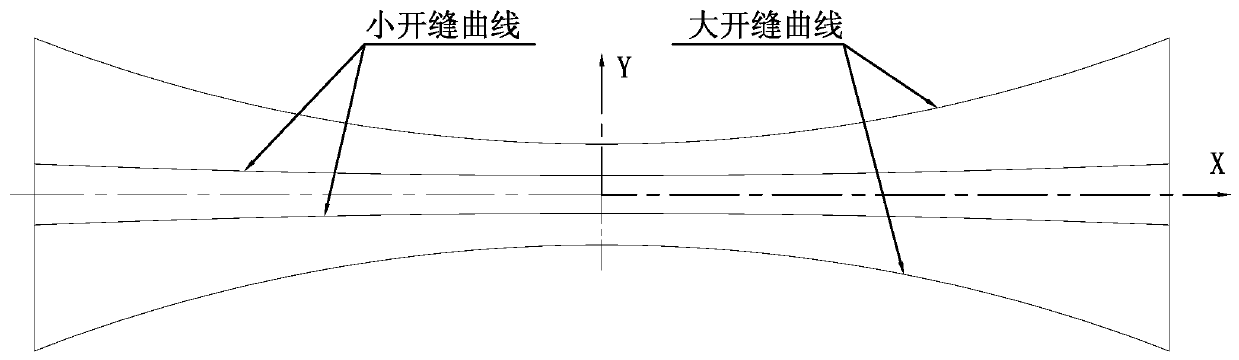

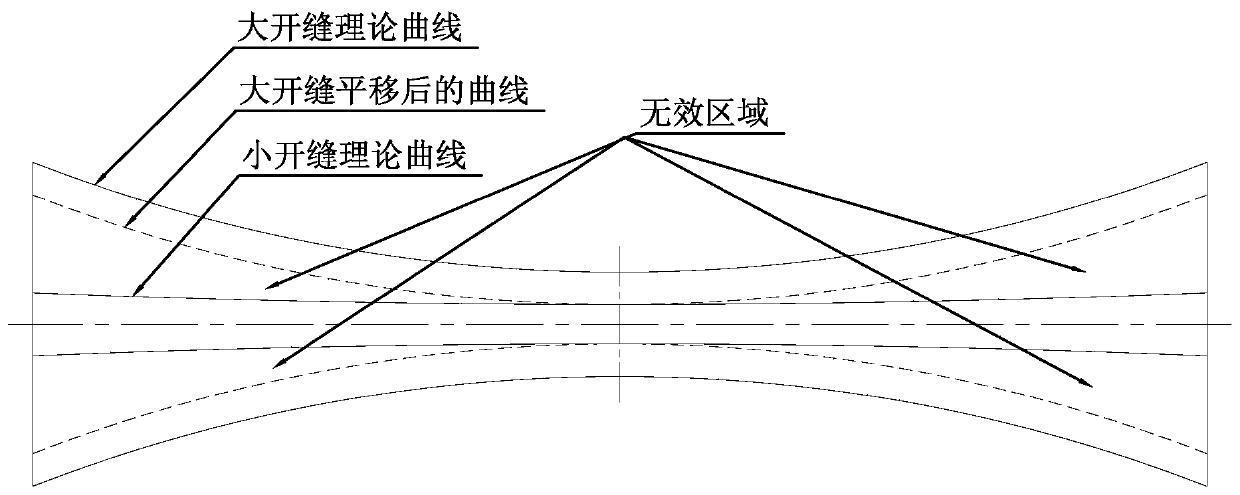

[0025] This embodiment proposes a slit segmented stepless adjustable collimator, such as Figures 5 to 7 As shown, the base 1 is included, and the base 1 is slidably connected with two opposite supports 2, and the support 2 is provided with a plurality of gates distributed along the length direction of the support 2, and the adjacent two gates and the support 2 are connected by a pin shaft, and a slit is formed between the gate plates on the two supports 2; a connecting plate 10 is connected to the gate plate, and a follower 7 is connected to the connecting plate 10, and both sides of the base 1 A fixed plate 11 is connected, and a spring 13 is connected between the connecting plate 10 and the fixed plate 11. The side of the support 2 away from the gap is provided with an eccentric shaft 4 that is rotatably connected with the base 1. The eccentric shaft 4 is provided with a The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com