Freeze-drying processing method of figwort root

A processing method, vacuum freeze-drying technology, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of unsafety, limited use range, and inability to effectively retain the active ingredient harpaside of Scrophulariaceae , to achieve the effect of avoiding damage and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

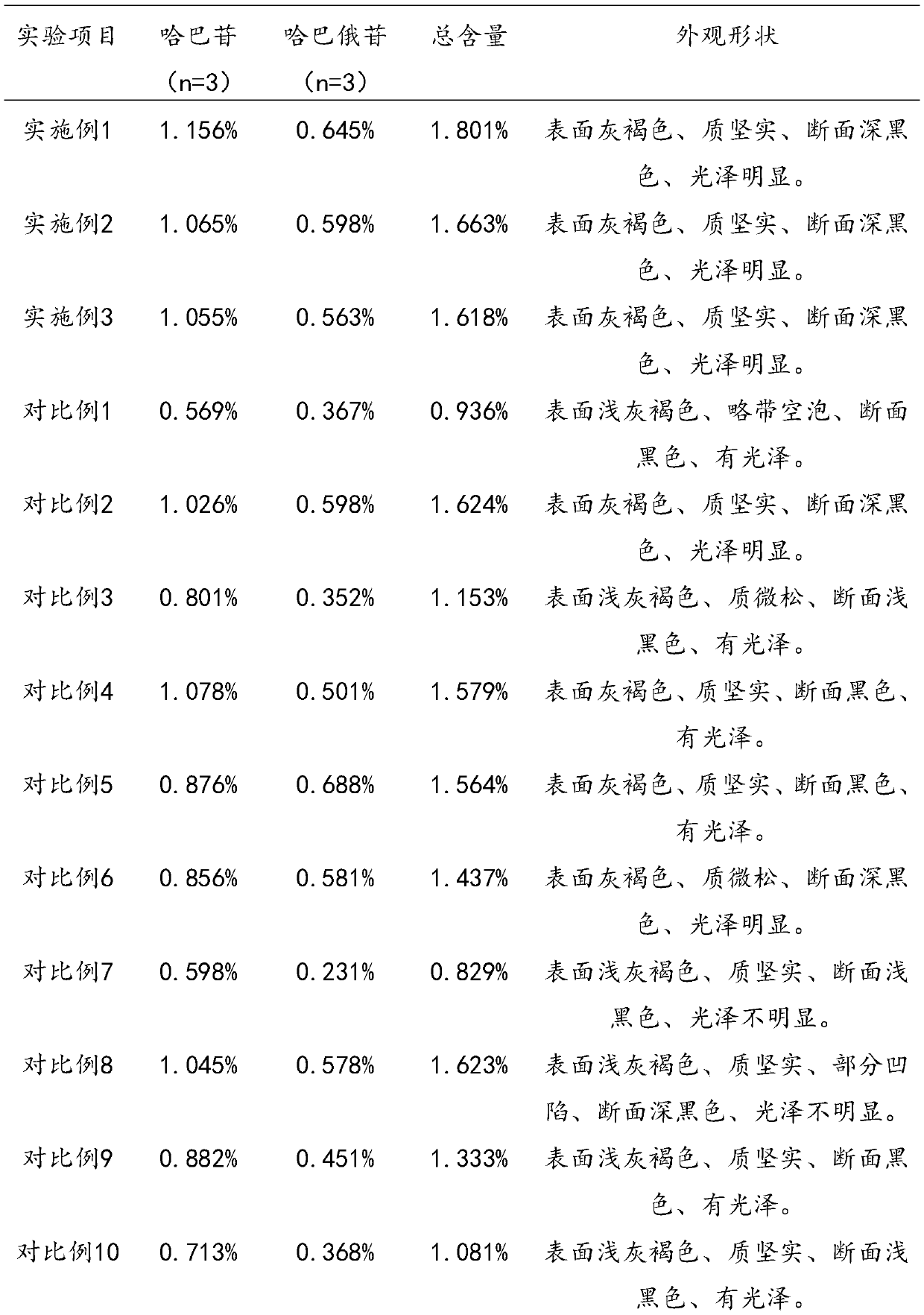

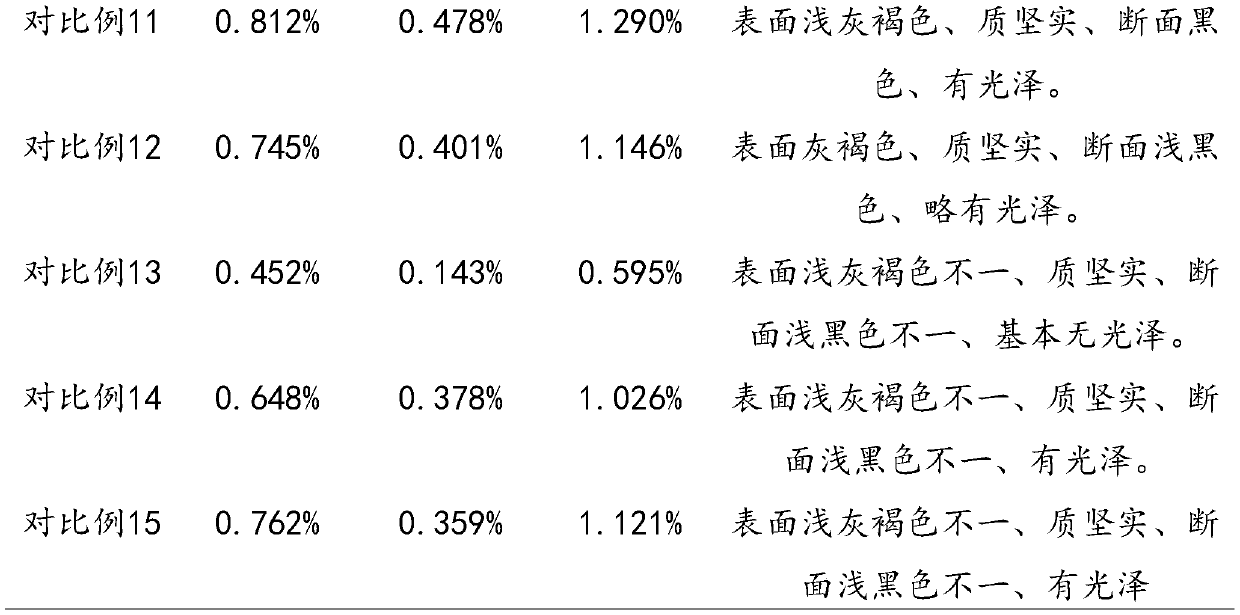

Examples

Embodiment 1

[0033] (1) Material selection: Fresh Scrophulariaceae excavated when the stems and leaves wither in winter, remove the rhizomes, young shoots, fibrous roots and sediment, clean, drain, and cut into thin slices with a thickness of 1-3mm while fresh.

[0034] (2) Pre-freezing: put clean Scrophulariaceae into a vacuum freeze dryer for pre-freezing at -10°C for 3 hours to obtain pre-frozen Scrophulariaceae.

[0035] (3) Step-by-step freezing: The pre-frozen Scrophulariaceae is subjected to step-by-step freezing in three stages: the first stage, from -15°C to -25°C, cooling at a rate of 0.7°C / min for 3 hours; the second stage, From -25°C to -35°C, cool down at a rate of 0.7°C / min for 3 hours; in the third stage, from -35°C to -40°C, cool down at a rate of 1.5°C / min for 1.5h.

[0036] (4) Heating and drying: the vacuum degree is 60±5Pa, and it is carried out in three stages: the first stage, from -45°C to -20°C, the temperature is raised at a rate of 0.7°C / min, and lasts for 4h; the...

Embodiment 2

[0039] (1) Material selection: Fresh Scrophulariaceae excavated when the stems and leaves wither in winter, remove the rhizomes, young shoots, fibrous roots and sediment, clean, drain, and cut into thin slices with a thickness of 1-3mm while fresh.

[0040] (2) Pre-freezing: put clean Scrophulariaceae into a vacuum freeze dryer for pre-freezing at -5°C for 2 hours to obtain pre-frozen Scrophulariaceae.

[0041] (3) Step-by-step freezing: The pre-frozen Scrophulariaceae is subjected to step-by-step freezing in three stages: the first stage, from -15°C to -25°C, cooling at a rate of 0.5°C / min for 2 hours; the second stage, From -25°C to -35°C, cool down at a rate of 0.5°C / min for 2 hours; in the third stage, from -35°C to -40°C, cool down at a rate of 1°C / min for 1 hour.

[0042] (4) Heating and drying: the vacuum degree is 60±5Pa, and it is carried out in three stages: the first stage, from -45°C to -20°C, the temperature is raised at a rate of 0.5°C / min for 3 hours; the second...

Embodiment 3

[0045] (1) Material selection: Fresh Scrophulariaceae excavated when the stems and leaves wither in winter, remove the rhizomes, young shoots, fibrous roots and sediment, clean, drain, and cut into thin slices with a thickness of 1-3mm while fresh.

[0046] (2) Pre-freezing: put clean Scrophulariaceae into a vacuum freeze dryer for pre-freezing at -15°C for 4 hours to obtain pre-frozen Scrophulariaceae.

[0047] (3) Step-by-step freezing: The pre-frozen Scrophulariaceae is subjected to step-by-step freezing in three stages: the first stage, from -15°C to -25°C, cooling at a rate of 1°C / min for 4 hours; the second stage, From -25°C to -35°C, cool down at a rate of 1°C / min for 4 hours; in the third stage, from -35°C to -40°C, cool down at a rate of 2°C / min for 2 hours.

[0048] (4) Heating and drying: the vacuum degree is 60±5Pa, and it is carried out in three stages: the first stage, from -45°C to -20°C, the temperature is raised at a rate of 1°C / min, and lasts for 6h; the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com