Full-automatic flushing device and flushing method for gilled radiator of transformer

A flushing device and transformer technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of extended construction period, difficult monitoring, manual work, etc., and achieve the goal of shortening flushing time and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

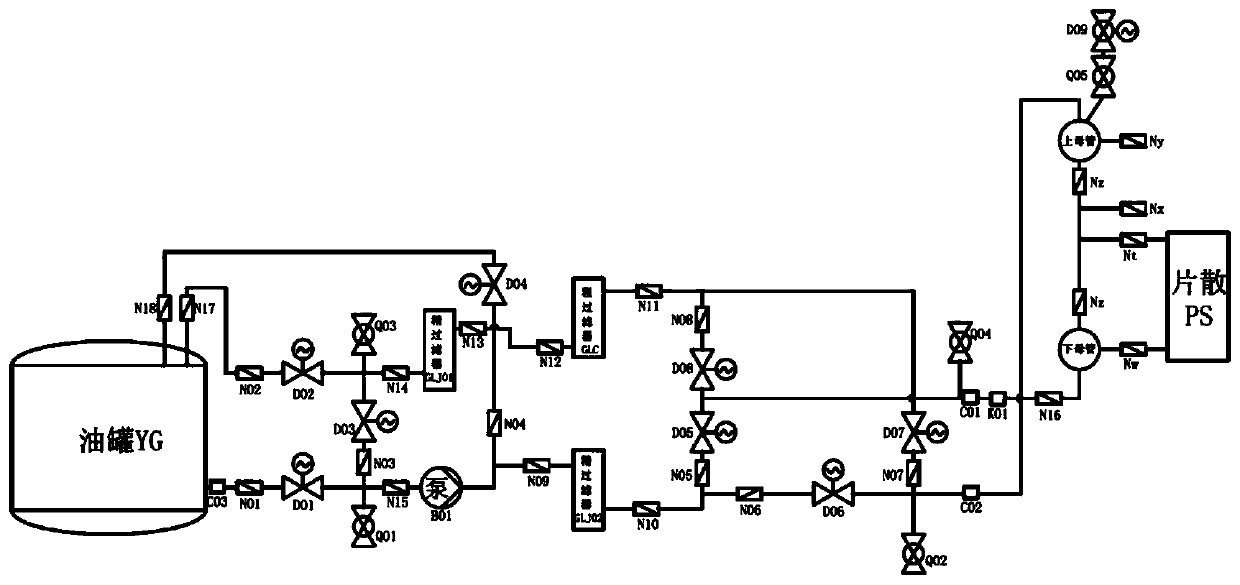

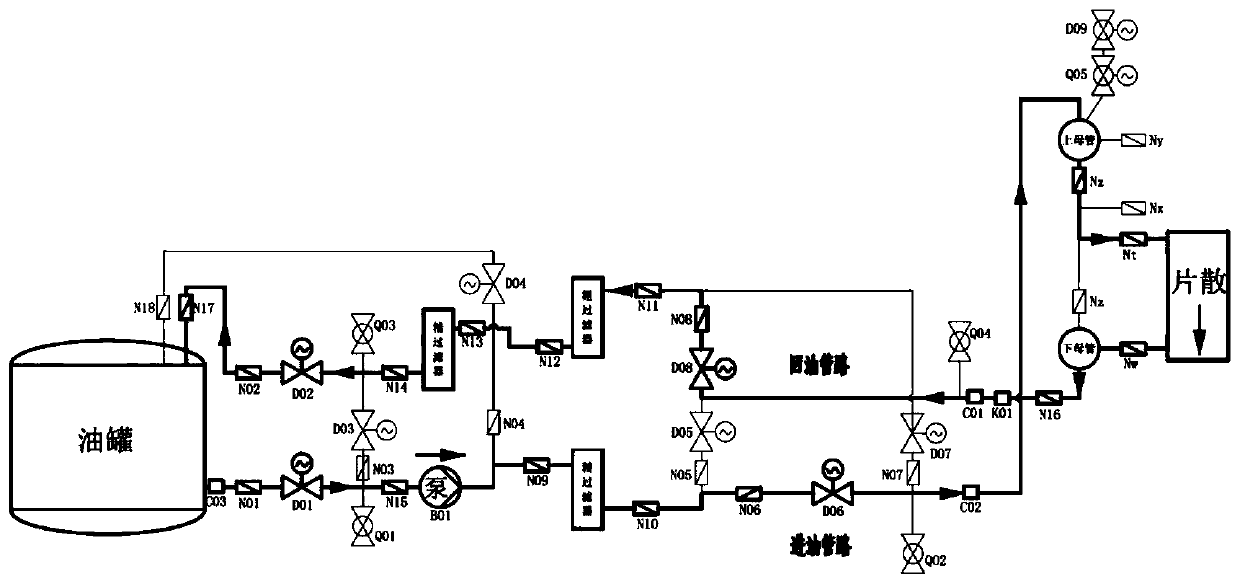

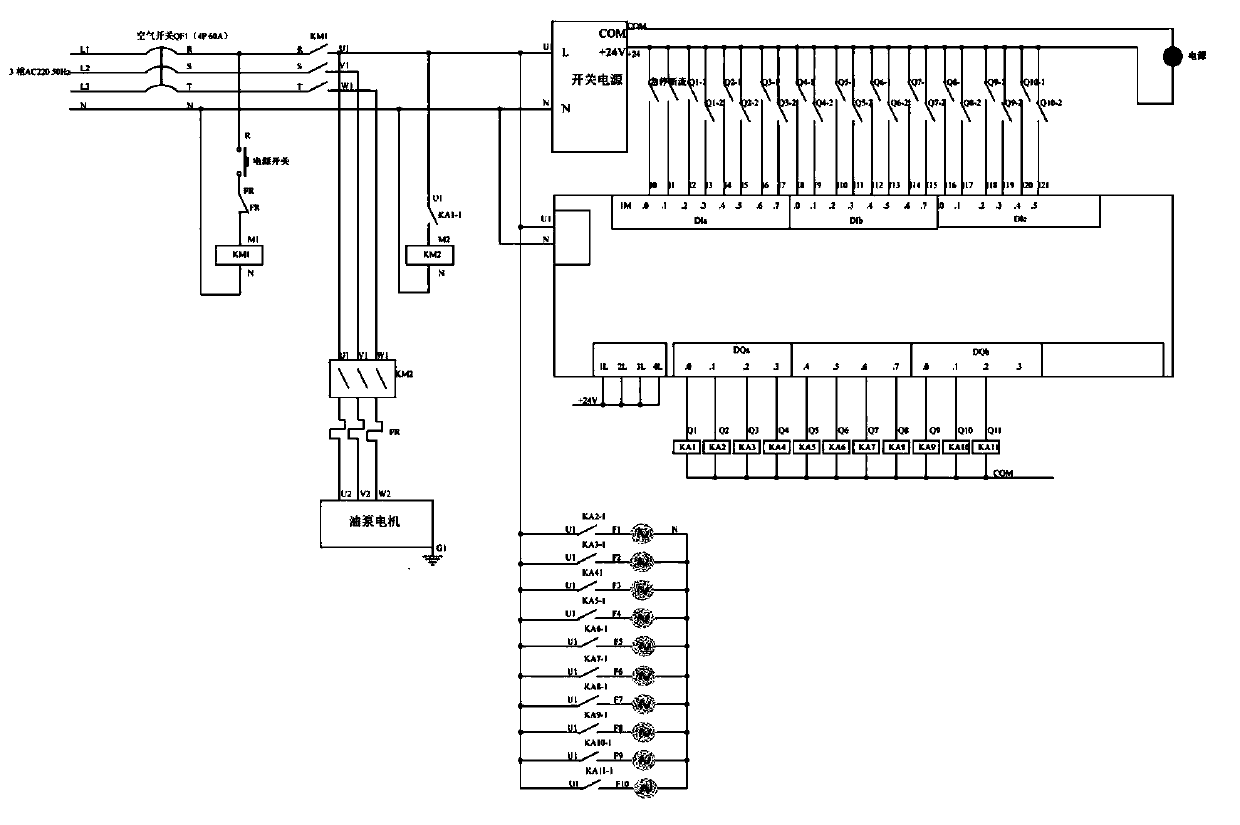

[0031] A fully automatic flushing device for transformer chips, comprising: an integrated control cabinet equipped with a touch screen and a PLC control device, and a flushing pipeline for connecting an oil storage tank and the chips, and the flushing pipeline drives oil to flow in the pipeline It consists of an oil pump, electric valve, electric ball valve, manual ball valve, manual butterfly valve, coarse filter and fine filter. The flushing pipeline includes: the first pipeline - chip flushing oil inlet pipeline, the second pipeline - chip flushing return The oil pipeline, the third pipeline-chip oil drain pipeline, the fourth pipeline-external oil filter flushing pipeline; the electric valve and electric ball valve are electrically connected with the PLC control device through cable accessories; the PLC The control device is provided with a control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com