A drop hammer compaction machine

A drop-weight, mechanical technology, applied in the field of mechanical equipment, can solve the problems of unsuitable joints of two bridge piers and limited application scope of the roller car, so as to improve the practicability, the movement direction and the force direction are consistent, and the applicability is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

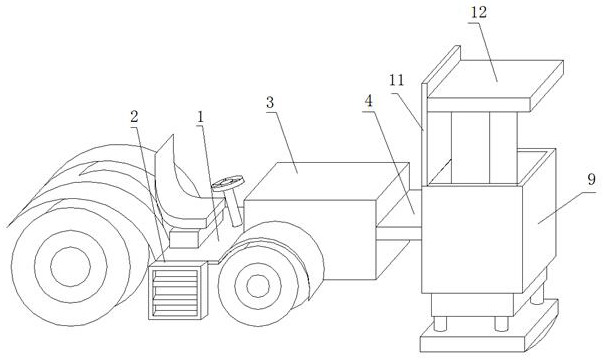

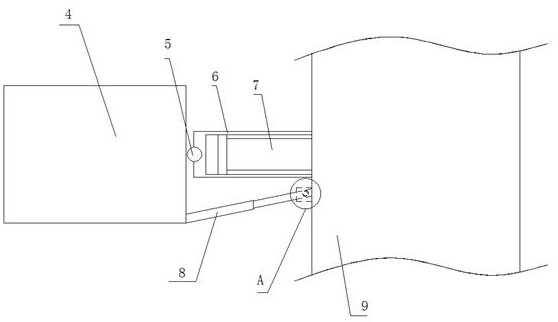

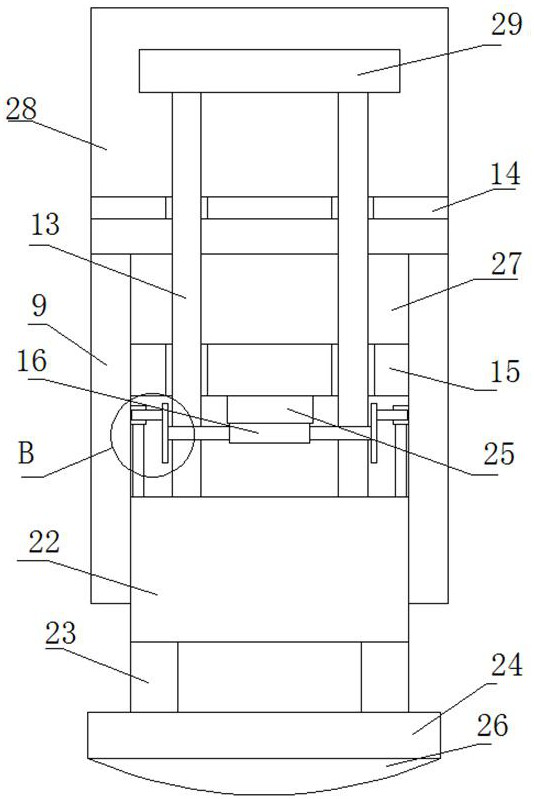

[0024] refer to Figure 1-5 In this embodiment, a drop hammer type compaction machine is proposed, which includes a body 1, a chassis 3 is arranged on the body 1, a horizontal bar 4 is fixedly installed on one side of the chassis 3, and a horizontal bar 4 is rotatably installed on one side Support 6, a support rod 7 is slidably installed on the side away from the chassis 3, and a mounting plate 9 is fixedly installed on one side of the support rod 7, and a hydraulic cylinder 8 is fixedly installed on one side of the bar 4, and the hydraulic cylinder 8 is inclined, one end of the output shaft of the hydraulic cylinder 8 is flexibly connected to one side of the mounting plate 9, the top of the mounting plate 9 is provided with a through groove 27, and the top of the mounting plate 9 is fixedly installed with a mounting block 28, and one of the mounting blocks 28 Slide plate 29 is installed on the side slidingly, and the bottom of slide plate 29 is fixedly installed with two slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com