Construction method for dredging backward by cutter suction vessel

A construction method and technology of cutter suction ship, which are applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Dig deep and dig for accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

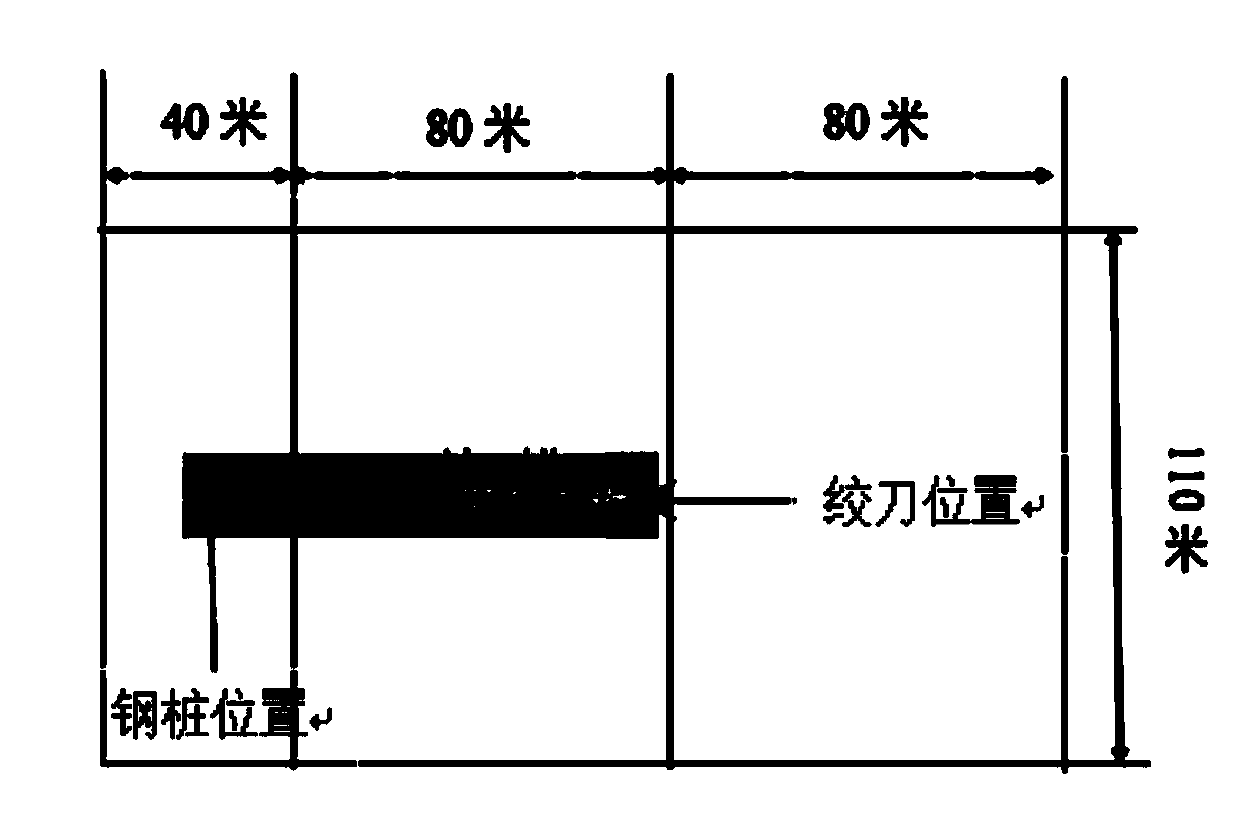

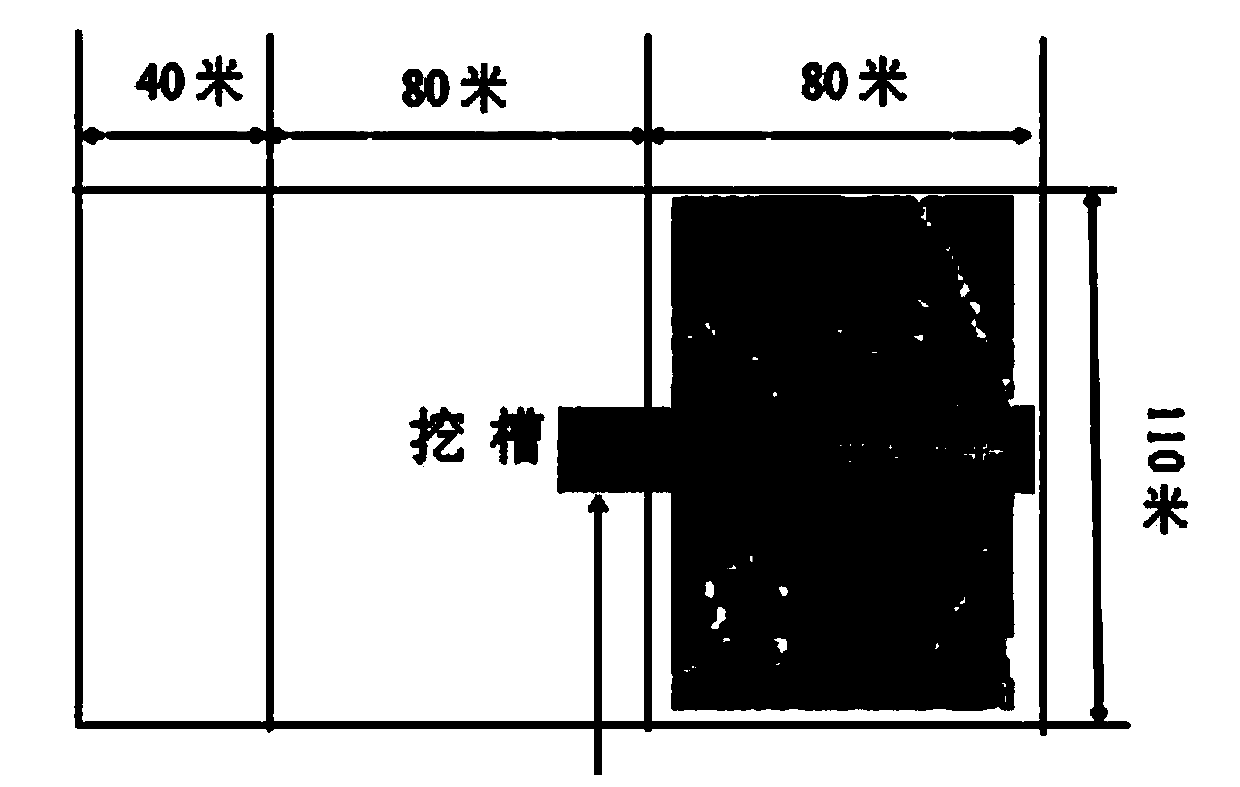

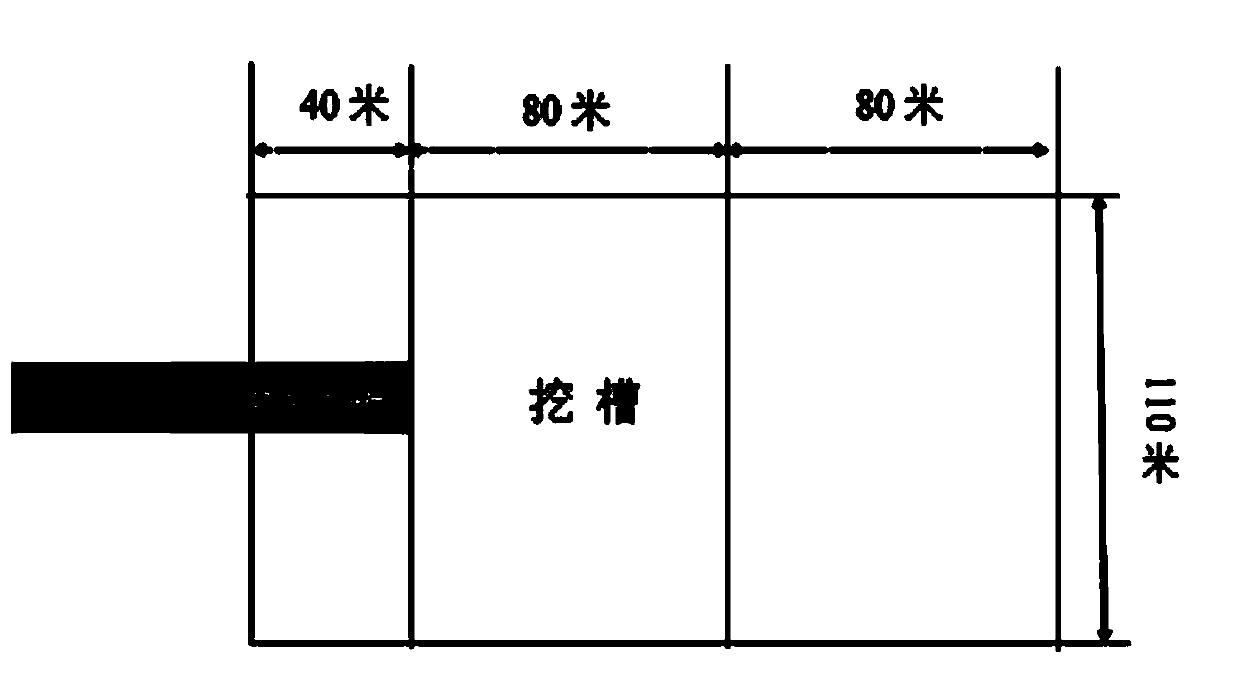

[0035] Such as Figure 1-Figure 8 As shown, according to an embodiment of the construction method of the cutter suction ship stepping back and dredging provided by the present invention, the length of the construction hull is 108 meters in this embodiment, the width of the construction ship is 18.2 meters, and the depth of the mold is 5.2 meters. According to the engineering characteristics and the design of the construction ship According to the parameter requirements, the length of the design construction area is determined to be 200 meters, the width is 110 meters, and the water depth after dredging is required to be -25 meters.

[0036] In this embodiment, according to the construction area and the length of the construction hull, the length of the ship is 108 meters, the distance from the positioning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com