Method for measuring surface roughness based on wavelet Brownian motion texture fusion model

A technology of Brownian motion and fusion model, applied in the direction of electrical digital data processing, character and pattern recognition, special data processing applications, etc., can solve the problems of narrow measurement range, eccentricity and vibration sensitivity, small measurement range, etc., and achieve simple measurement equipment , Ensure accuracy and stability, low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further clarified below in conjunction with specific drawings and embodiments.

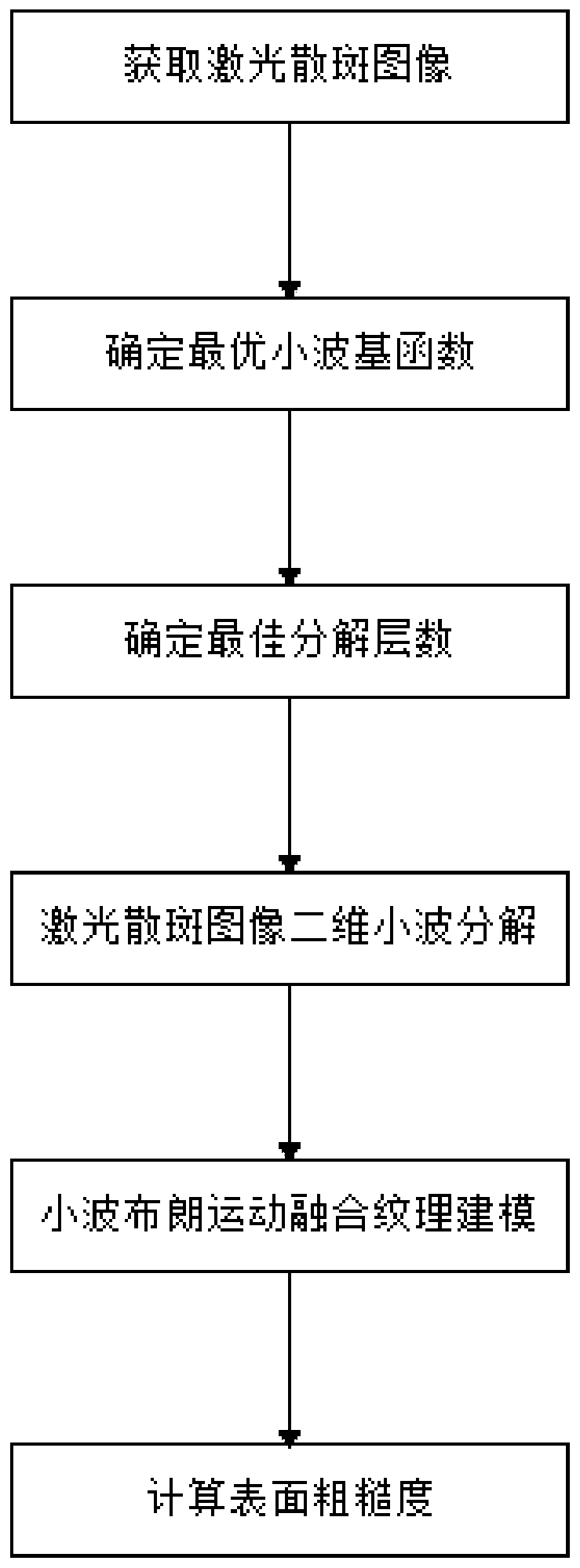

[0074] combine figure 1 As shown, what the present invention provides is a kind of method for measuring surface roughness based on wavelet Brownian motion texture fusion model, and this method specifically comprises the following steps:

[0075] (1) Build an experimental platform to obtain a laser speckle image of the workpiece to be tested;

[0076] (2) Utilize the laser speckle image acquired in step (1) to determine the optimal wavelet basis function;

[0077] (3) Determine the optimal wavelet decomposition layers;

[0078] (4) performing two-dimensional wavelet decomposition on the laser speckle image obtained in step (1);

[0079] (5) Using the method of wavelet Brownian motion texture fusion to carry out modeling analysis and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com