Correction method considering influence of local structure in reactor core flow field calculation

A technology of flow field calculation and local structure, which is applied in calculation, special data processing application, image data processing, etc., can solve the problem that the local flow field of the positioning grid cannot be reflected, and achieves strong versatility of the method, high accuracy of calculation results, The effect of less computing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

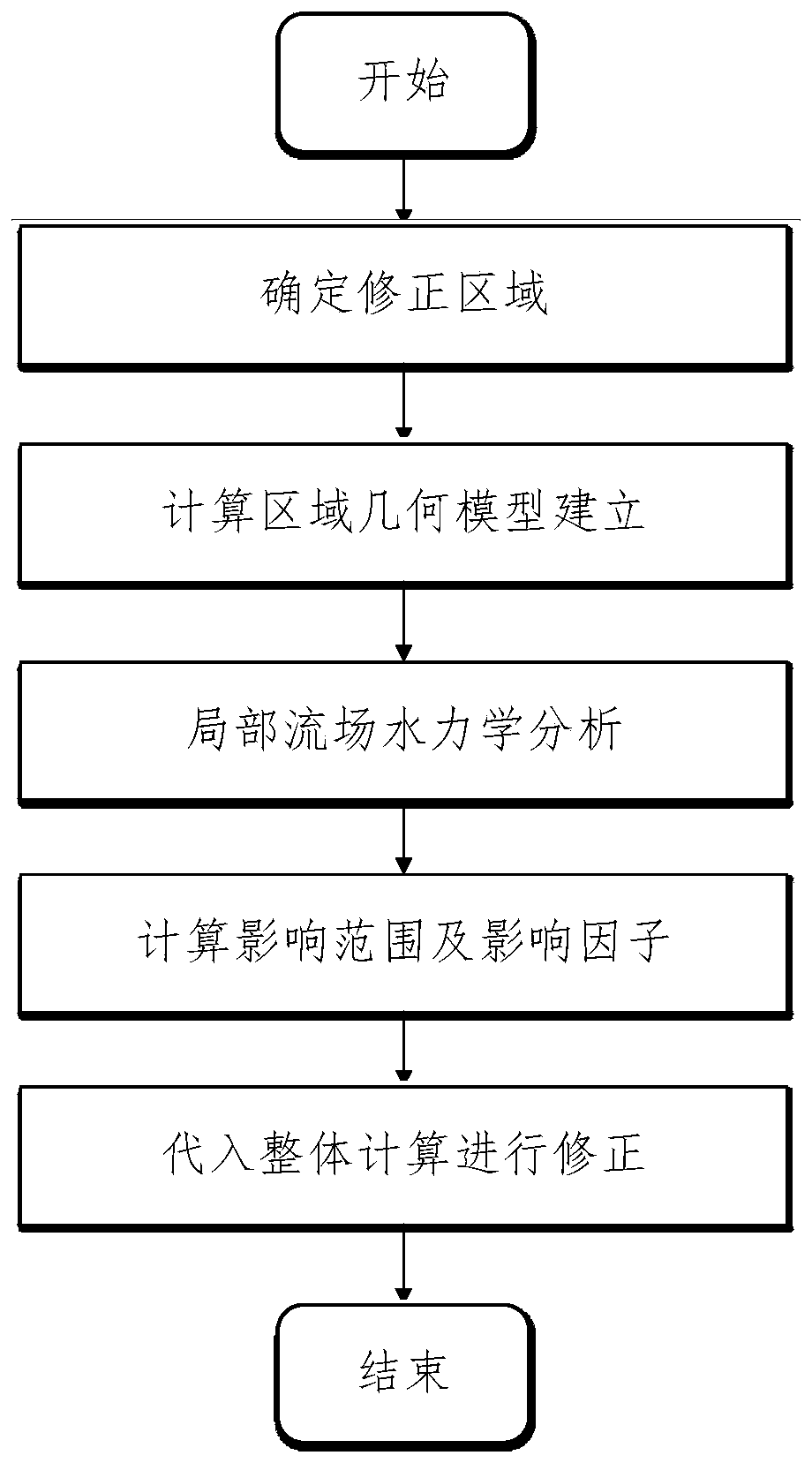

[0043] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0044] Such as figure 2 As shown, the present invention is a correction method that considers the influence of local structures in the calculation of the reactor core flow field, and the steps are as follows:

[0045] Step 1: Determine the correction area:

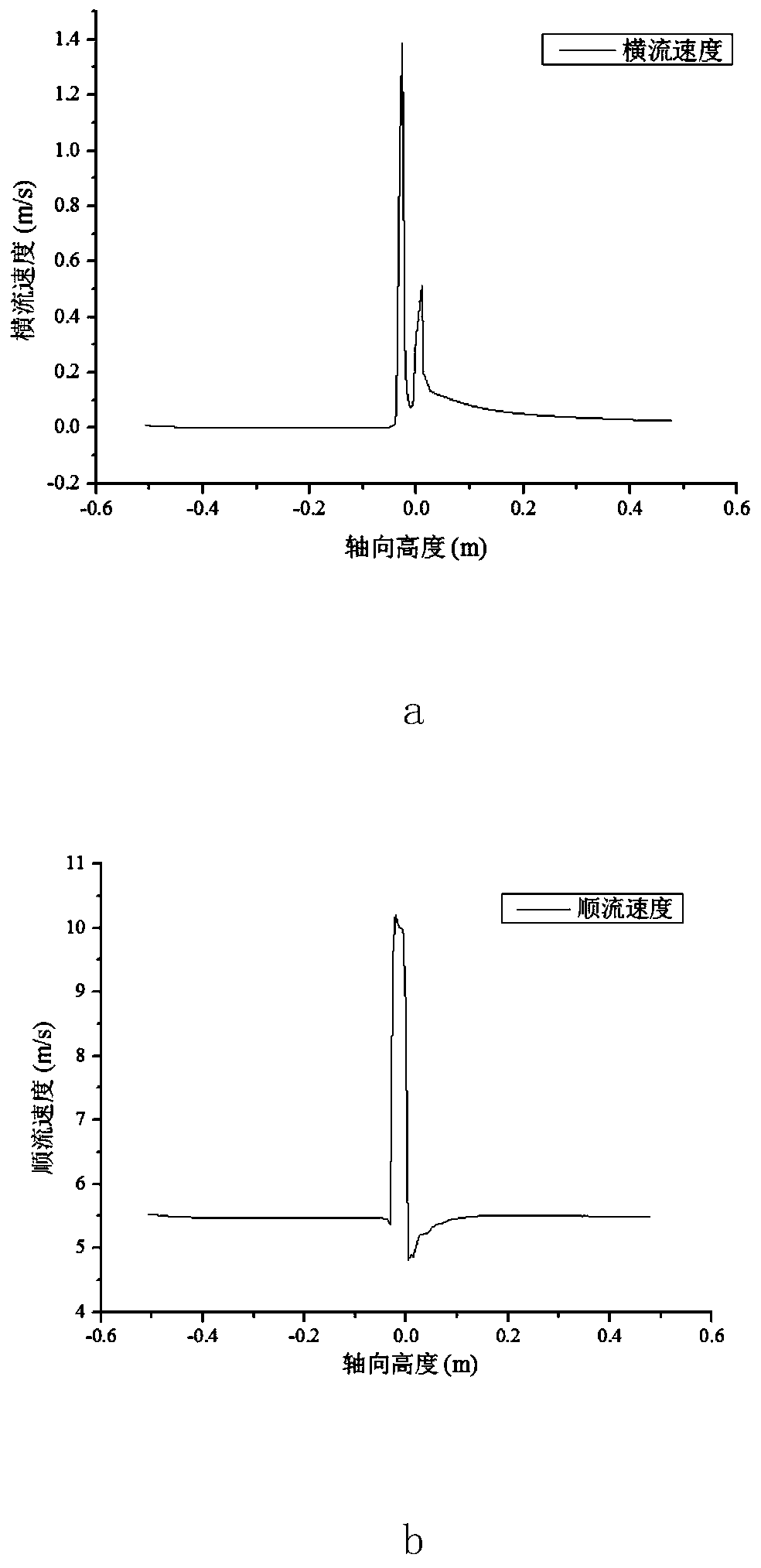

[0046] First, determine the local area that needs to be corrected in the overall calculation of the 3D thermal-hydraulic characteristics of the core flow field; in the 3D analysis program of the core flow field, only the porous The overall thermal and hydraulic parameter distribution of the components is studied, but the influence of the positioning grid on the local flow field is not considered; and these local parameters, mainly the local velocity distribution, are important in the safety and economic analysis of the fuel core flow field. It is a very important input condition in the performance analysis; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com