Liquid cooling system of power battery and control method of liquid cooling system of power battery

A power battery and control method technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of different charging and discharging capabilities of batteries, lowering the temperature of battery boxes, and temperature instability, so as to improve insulation and battery stability. Capability and service life, narrow temperature difference range, and good temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

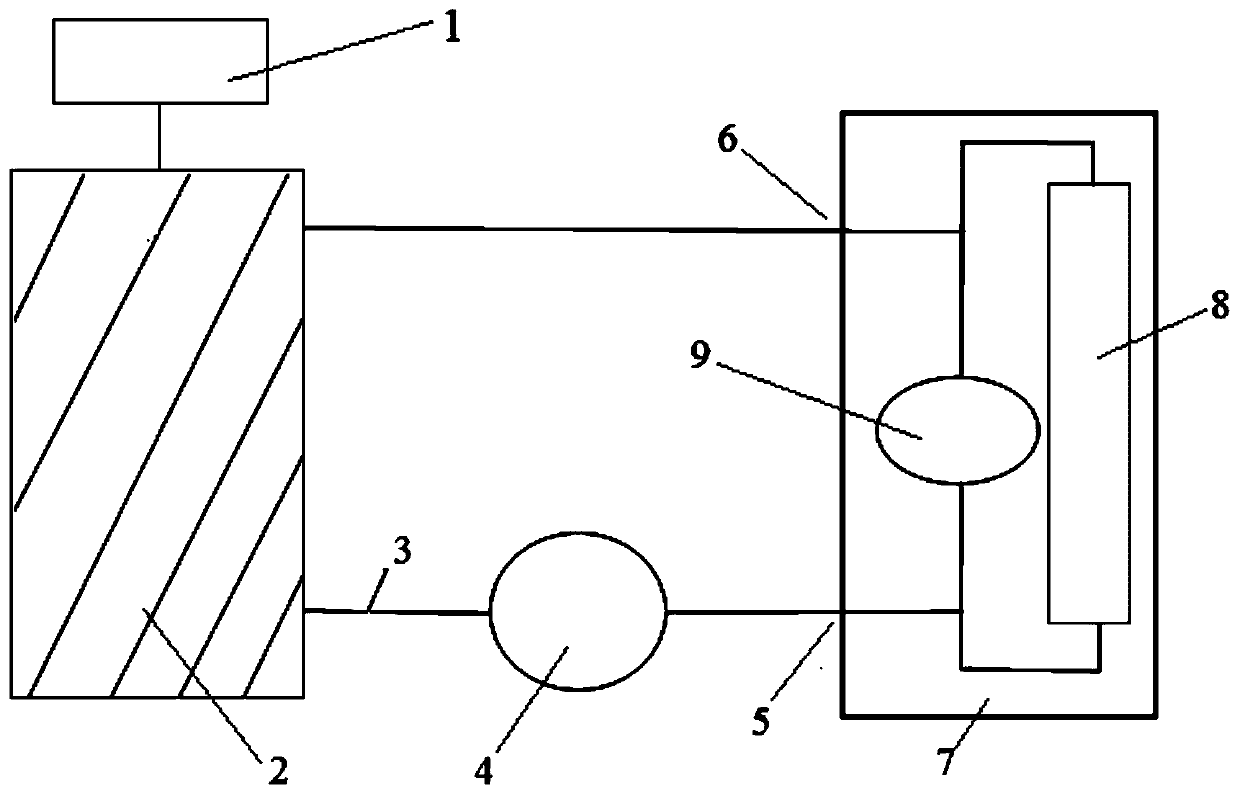

[0038] The first embodiment, such as figure 1 Shown:

[0039] In order to overcome the defects of the prior art and achieve the purpose of the invention to improve the temperature consistency of the battery core, the technical solution adopted by the present invention is:

[0040] Such as figure 1 As shown, in the liquid cooling system of the power battery of the present invention, the battery box 7 is provided with an internal circulating water channel, which communicates with the two pipes 3 connected to the radiator 2 .

[0041] A small water pump 9 is set on the internal circulating waterway. A small water pump 9 with very small power and volume is installed inside the battery box 7, and the temperature of the battery box when the liquid cooling system is turned on is preset at 35°C or the temperature difference of the battery cells is 5°C. That is: the preset temperature is 35°C; the preset temperature difference is 5°C.

[0042] The small water pump 9 is installed in...

no. 2 example

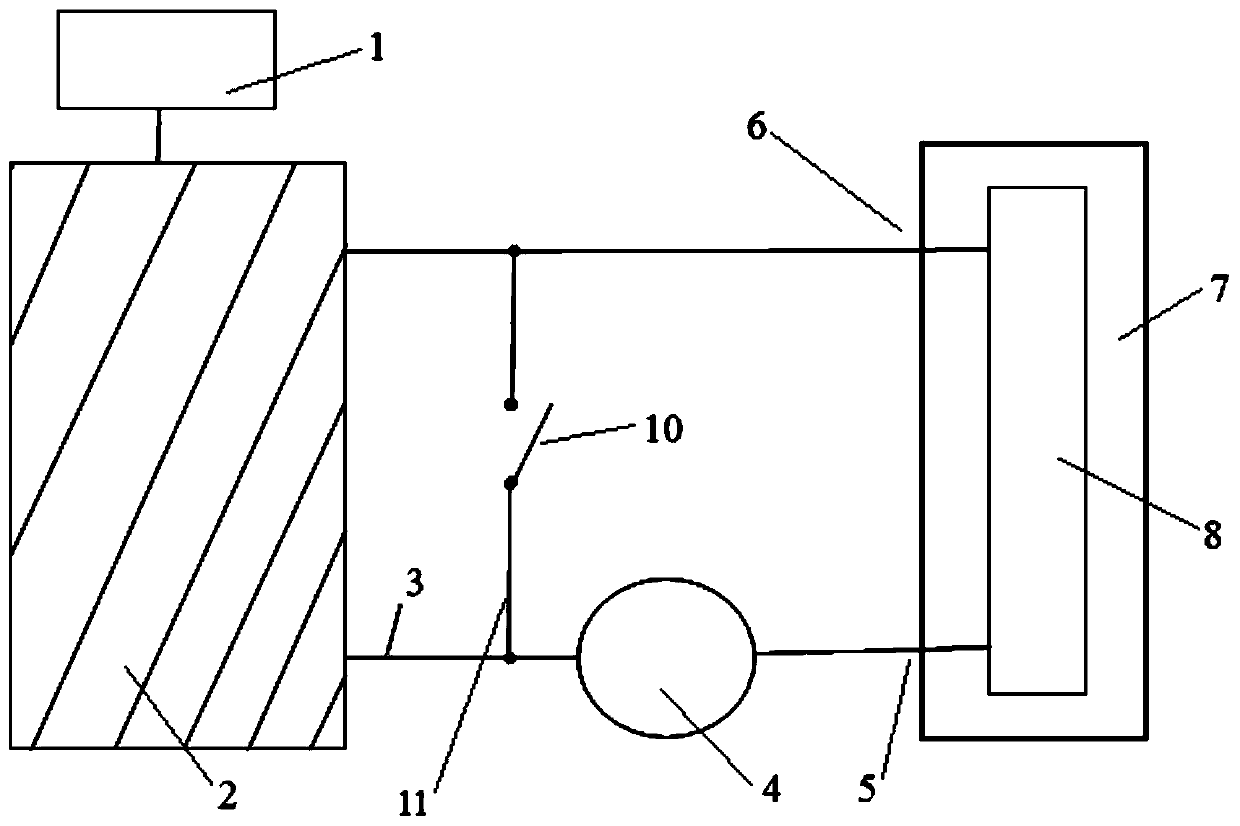

[0051] Second embodiment, such as figure 2 Shown:

[0052] The present invention also provides a liquid cooling system for a power battery, the power battery includes a battery core 8 arranged in a battery box 7, the liquid cooling system includes an expansion tank 1, a radiator 2 and an external circulation water pump 4, The radiator 2 is respectively connected to the liquid inlet 5 and the liquid outlet 6 of the battery box 7 through two pipelines 3; the two pipelines 3 are connected through an intermediate pipeline 11; Temperature control switch 10.

[0053] A temperature control switch 10 is added, which is connected with the battery box before the water pump. The temperature control switch 10 can be connected with a temperature control switch 10 between the front of the external circulation water pump 4 and the liquid outlet 6 when the small water pump 9 is not installed in the battery box 7 .

[0054] When the temperature difference of the battery core 8 in the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com