Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display element

A technology of liquid crystal aligning agent and solvent, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve problems such as difficult to obtain reliable liquid crystal display elements, and achieve excellent display characteristics, excellent performance of pretilt angle, and liquid crystal orientation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

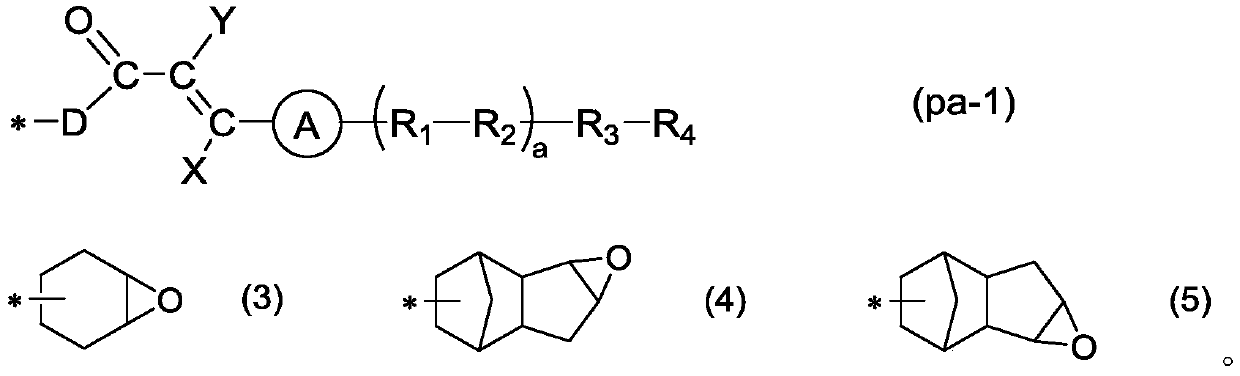

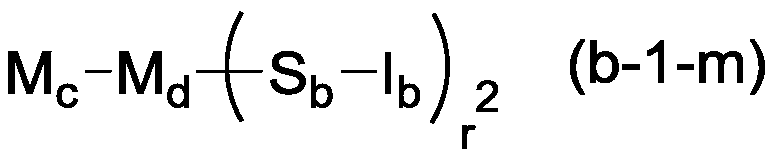

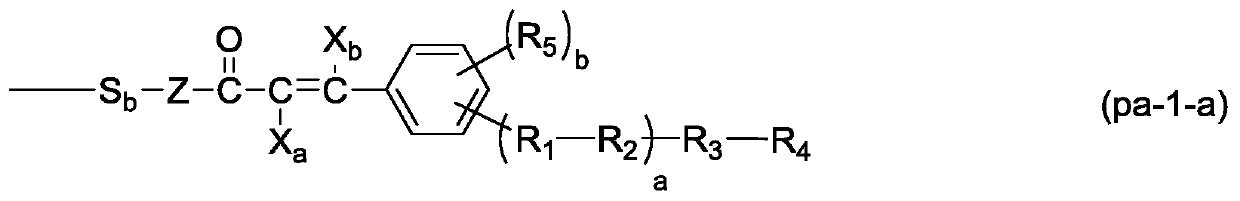

[0284] As a monomer having a photo-alignment group used in the examples (hereinafter referred to as "photo-alignment monomer"), monomers represented by "MA-1" and "MA-2" are as follows, as A monomer having a polar group (hereinafter referred to as "polar monomer"), a monomer represented by "MAA" or "VBA" is as follows, as a monomer having a crosslinkable group (hereinafter referred to as "cross-linking monomer"), the monomer represented by "GMA" is as follows, as the compound (B) component (hereinafter referred to as "cross-linking agent component"), "TETRAD-C" or " The structure of the compound represented by YH-434-L" is shown below.

[0285] In addition, "MA-2" was synthesize|combined by the synthesis method described in the following synthesis example 1. "MAA (methacrylic acid)", "VBA (vinylbenzoic acid)", "MMA", "C18", "TETRAD-C" and "YH-434-L" used commercially available reagents.

[0286] (photo-alignment monomer)

[0287]

[0288] (polar monomer)

[...

Synthetic example A1

[0339] Dissolve MA-2 (2.48 g, 6.01 mmol), GMA (0.14 g, 1.00 mmol) and MAA (1.2 g, 13.0 mmol) in CHN (11.0 g) and PGME (11.0 g) using a diaphragm pump After degassing, AIBN (0.2 g, 1.0 mmol) was added as a polymerization initiator, and degassing was performed again. Then, it was made to react at 60 degreeC for 13 hours, and the polymer solution (MP-1) was obtained.

[0340] The polymer had a number average molecular weight of 40,500 and a weight average molecular weight of 138,300.

Synthetic example A2~A10

[0341]

[0342] With the composition shown in Table 1, methacrylate polymers PA2-PA10 and PA11-PA18 were synthesized by the method similar to polymer synthesis example A1.

[0343]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com