High-strength liquid-phase dechlorinating agent and preparation method and application thereof

A dechlorination agent, high-strength technology, applied in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc., can solve the problems of complex preparation process, flammable activated carbon, three wastes discharge, etc., and achieve simple preparation, low cost, Ease of entry and exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

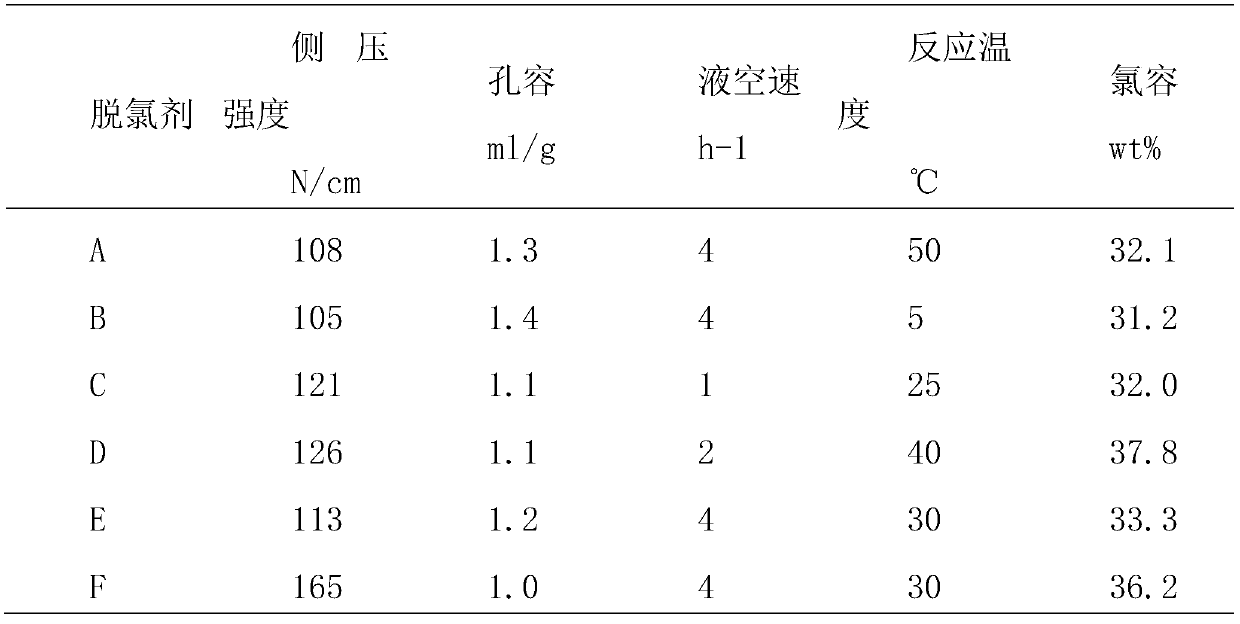

Examples

Embodiment 1

[0028] a) Weigh 60.0 grams of SiO 2 Diatomaceous earth powder, 2.0 grams of methylcellulose and 30.0 grams of Na 2 CO 3 Sodium carbonate powder, the three are mixed uniformly to obtain mixed powder;

[0029] b) Weigh 10.0 grams of sodium hydroxide, add about 80 milliliters of water, fully dissolve to obtain a clear and transparent solution;

[0030] c) adding the solution obtained in step b) to the powder obtained in step a), and fully kneading to obtain a plastic dough;

[0031] d) Extrude the plastic dough obtained in step c) and dry at 120°C for 2 hours, then bake at 500°C for 3 hours, and cool to obtain the dechlorinating agent A.

Embodiment 2

[0033] a) weigh 87.0 grams of SiO 2 Diatomaceous earth powder and 3.0 g methylcellulose powder 57.0 g K 2 CO 3 Potassium carbonate powder, the three are mixed uniformly to obtain mixed powder;

[0034] b) Weigh 13.0 grams of sodium hydroxide, add about 120 milliliters of water, fully dissolve to obtain a clear and transparent solution;

[0035] c) adding the solution obtained in step b) to the powder obtained in step a), and fully kneading to obtain a plastic dough;

[0036] d) Extrude the plastic dough obtained in step c) and dry at 150°C for 2 hours, then bake at 550°C for 2 hours, and cool to obtain the dechlorinating agent B.

Embodiment 3

[0038] 1) Weigh 35.0 grams of SiO 2 of diatomite powder, 1.0 g of squash gum and 55.0 g of Na 2 CO 3 Sodium carbonate powder, the three are mixed uniformly to obtain mixed powder;

[0039] 2) Weigh 10.0 grams of sodium hydroxide, add about 70 milliliters of water, fully dissolve to obtain a clear and transparent solution;

[0040] 3) adding the solution obtained in step b) into the powder obtained in step a), and fully kneading to obtain a plastic dough;

[0041] 4) Extrude the plastic dough obtained in step c) and dry at 120°C for 8 hours, then bake at 480°C for 4 hours, and cool to obtain the dechlorinating agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com