Phosphogypsum building block autoclaving system

A phosphogypsum and block technology, applied in the field of phosphogypsum block autoclave system, can solve the problems of energy waste, steam waste and high production cost, and achieve the effects of reducing production cost, saving resources and avoiding steam waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

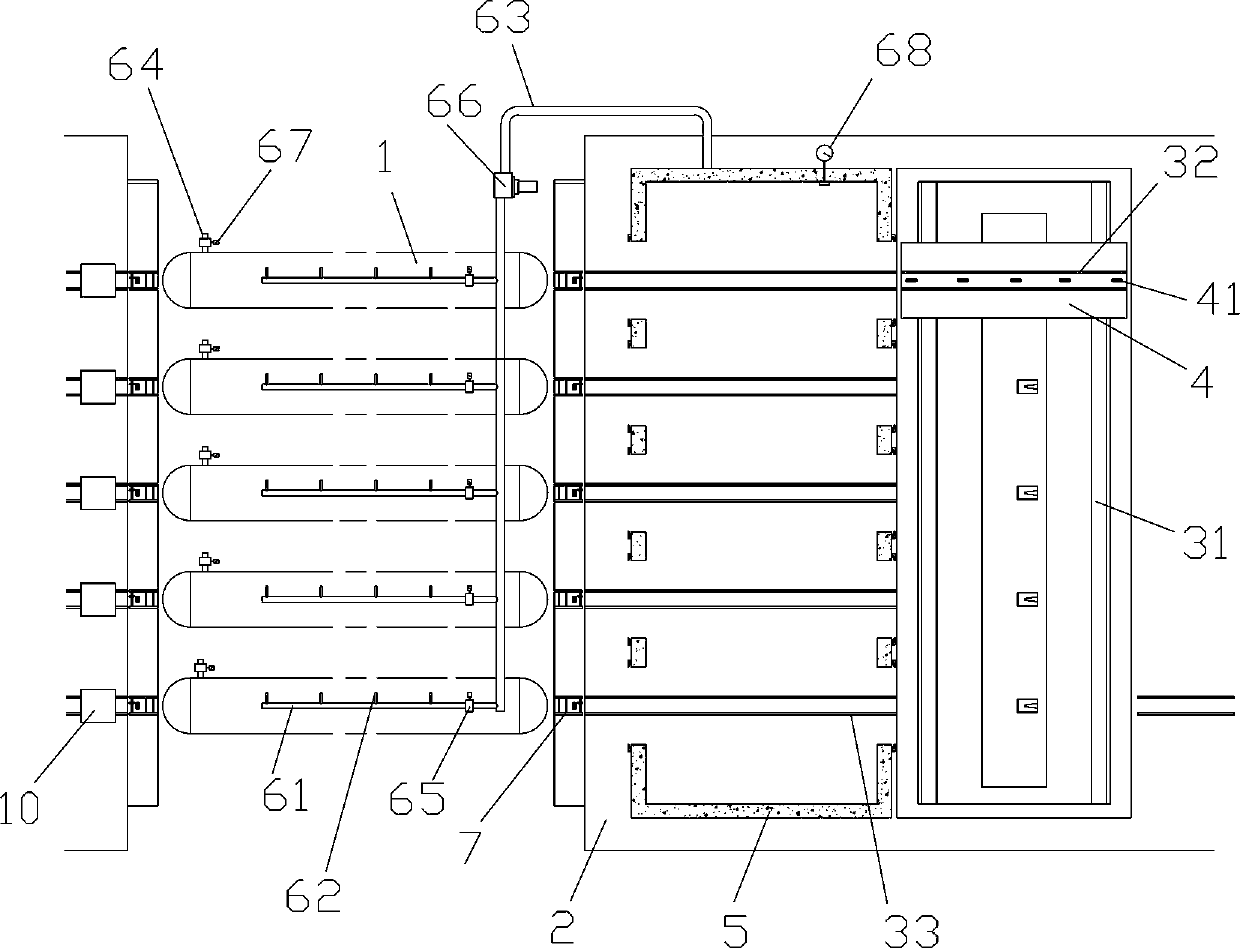

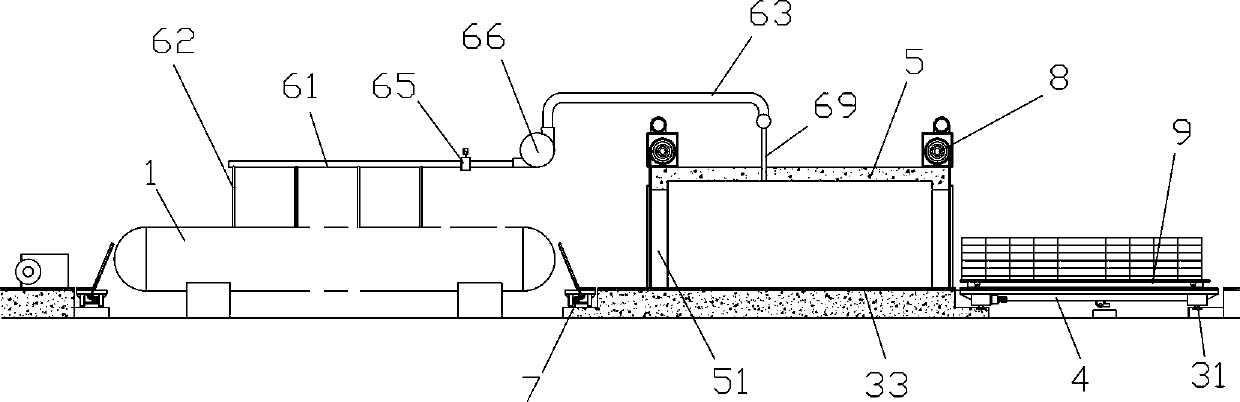

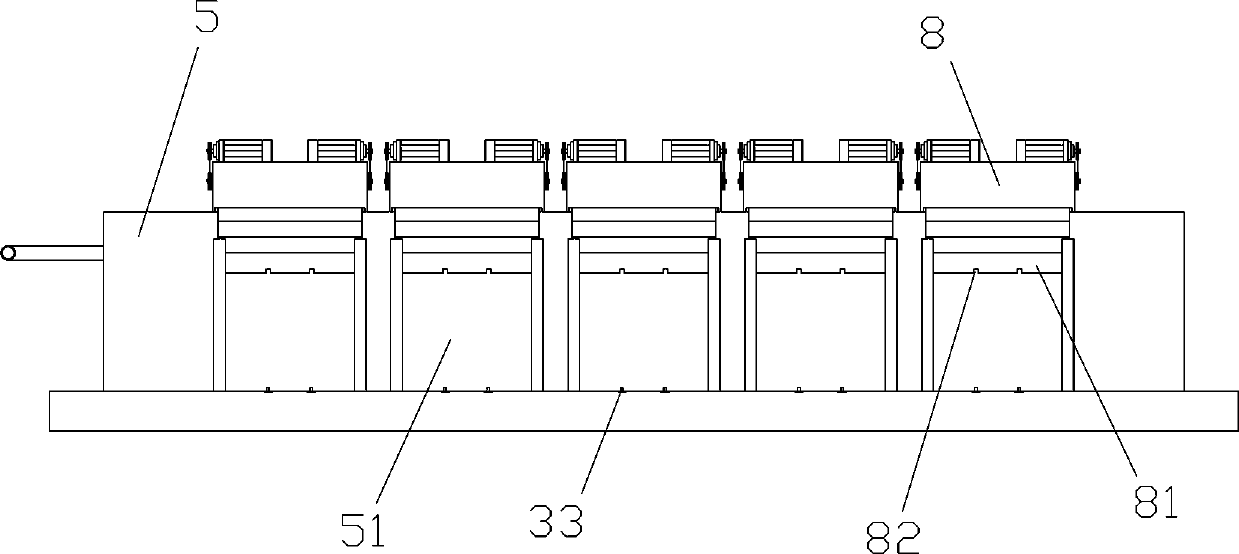

[0017] Such as Figures 1 to 6 As shown, a phosphogypsum block autoclaving system includes a plurality of autoclaves 1 arranged in sequence, a transfer table 2 is provided on one side of the autoclave 1, and a group of first guide rails 31 are arranged in the transfer table 2 , a ferry car 4 is provided on the first guide rail 31, and a group of second guide rails 32 and friction wheels 41 are installed on the shuttle car 4, and the friction wheel 41 is used to drive the steam press car 9 arranged on the second guide rail 32 to move forward , between the ferry car 4 and the autoclave 1, a plurality of sets of third guide rails 33 corresponding to each autoclave 1 are provided, and a third guide rail 33 is provided between each group of third guide rails 33 and each autoclave 1 The rail connection mechanism 7 also includes a control system and a preheating room 5 arranged on the transfer platform 2, each group of third guide rails 33 is located in the preheating room 5, and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com