Button cell detecting, labelling and packaging all-in-one machine

A button battery and all-in-one machine technology, applied in labeling machines, packaging, transportation and packaging, etc., can solve the problems of low efficiency of manual labeling, waste of manpower, time-consuming, etc., and achieve the effect of improving production packaging efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

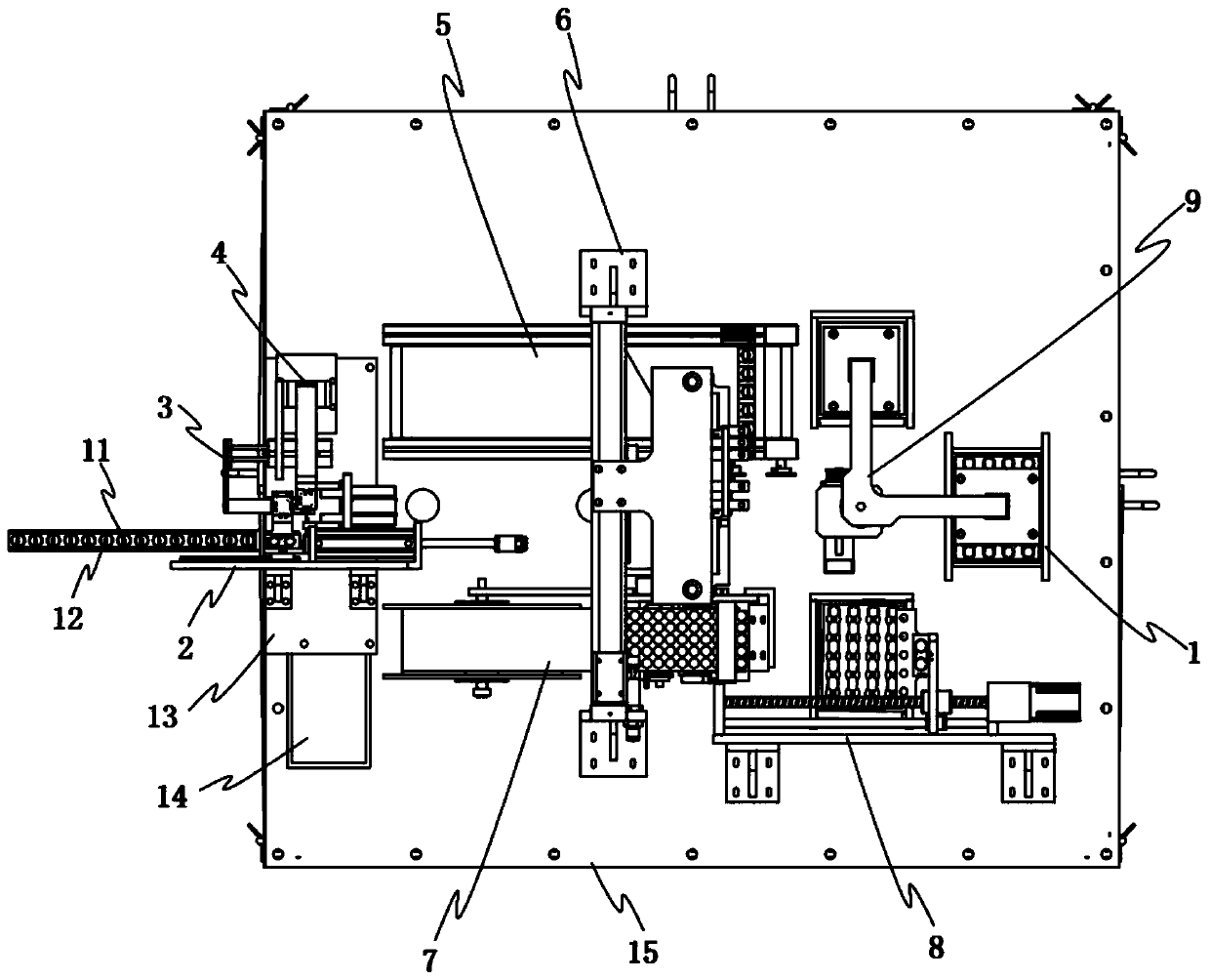

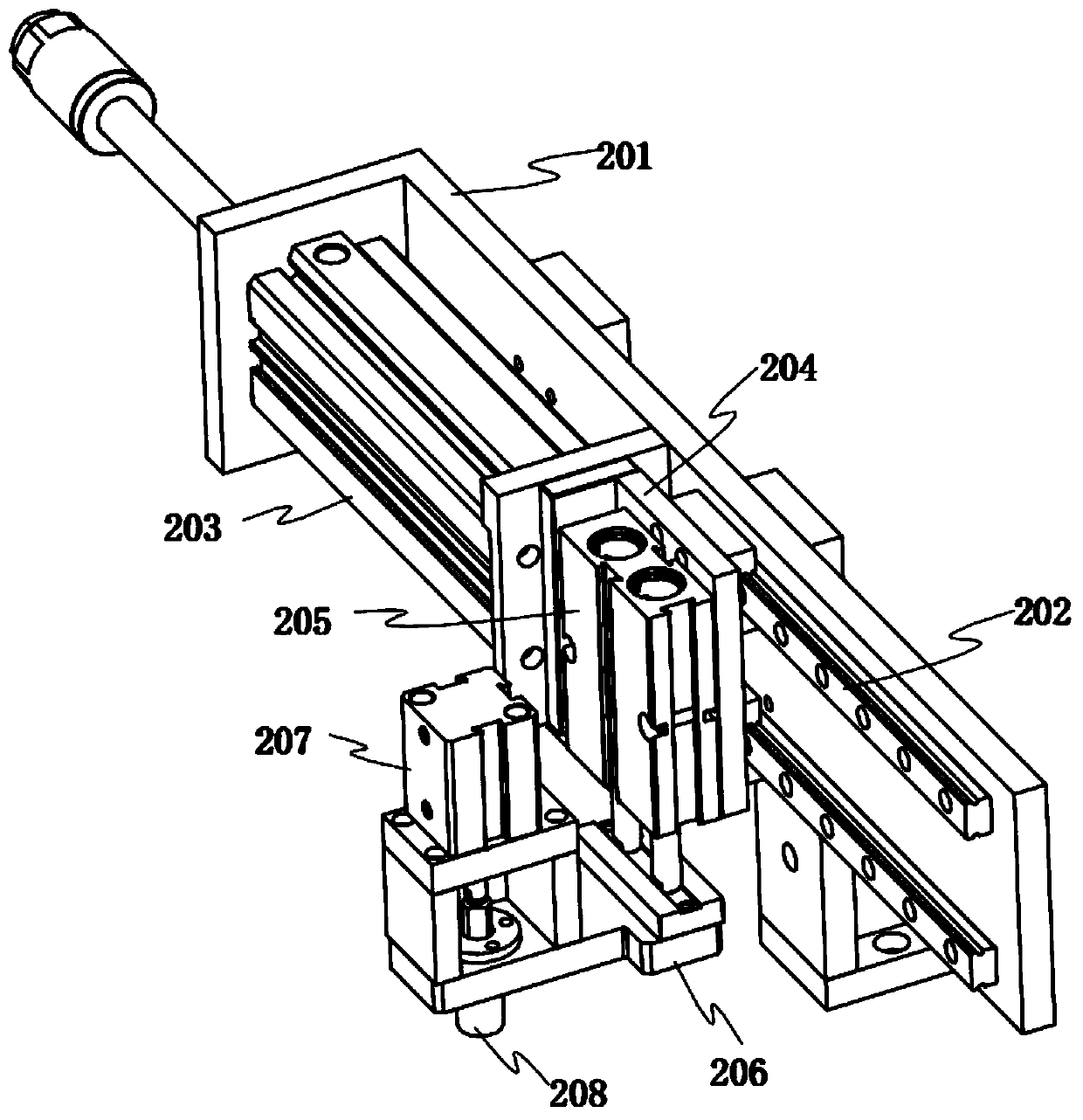

[0042]When the all-in-one machine is working, the button batteries 12 are input one by one by the input belt 11, and then the horizontal displacement of the battery input mechanism 2 drives the cylinder I203 to drive the suction nozzle I208 to move to the upper part of the button battery 12 on the output port of the input belt 11, and then the vertical displacement Cylinder Ⅰ drives the adsorption nozzle Ⅰ 208 to move down, and at the same time, the battery adsorption cylinder Ⅰ 207 drives the adsorption nozzle Ⅰ 208 to further move downward to absorb the button battery 12, and then the horizontal displacement driving cylinder Ⅰ 203 and the vertical displacement cylinder Ⅰ drive the adsorption nozzle Ⅰ 208 and the buttons it absorbs The battery 12 is moved to the plate groove of the detection groove plate 303 of the battery detection mechanism 3, and then the battery adsorption cylinder I207 drives the suction nozzle I208 to move down and the button battery 12 is placed in the p...

Embodiment 2

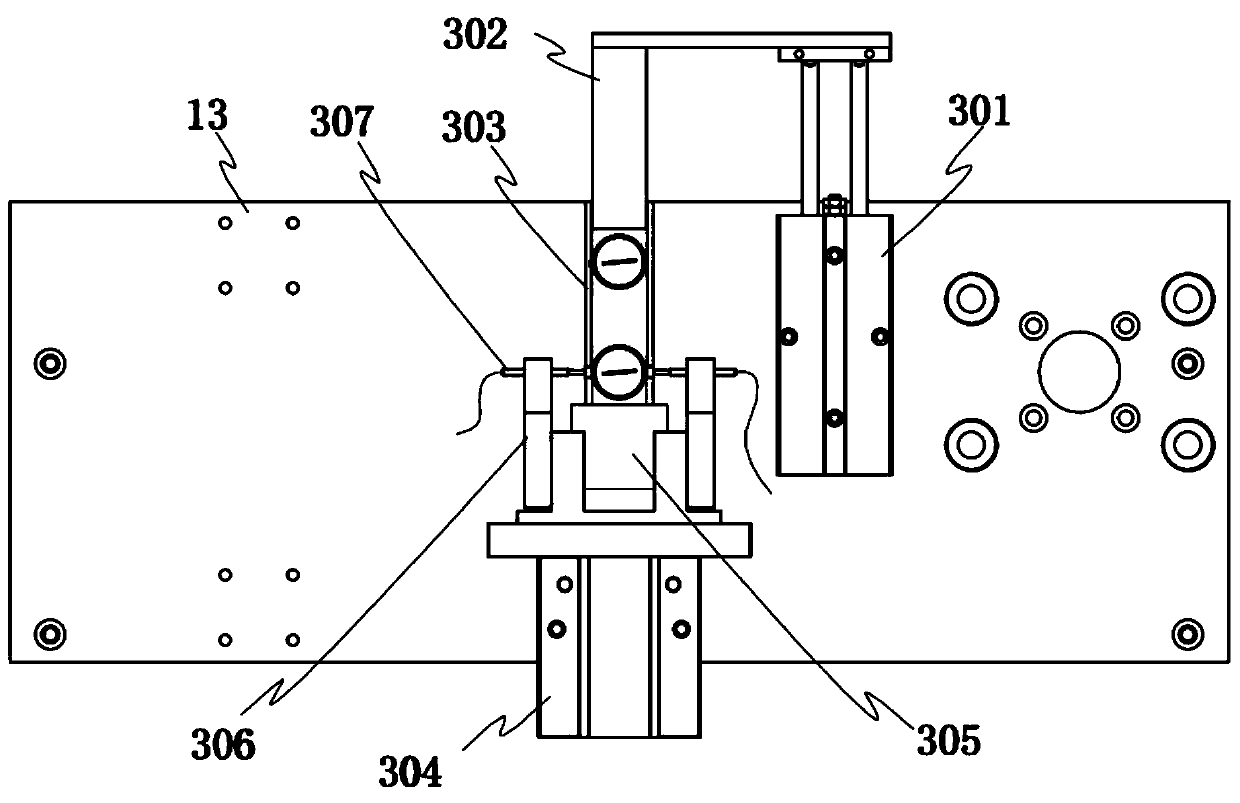

[0044] Start the push-in cylinder 301 of the battery detection mechanism 3, and the push-in cylinder 301 drives the push slat 302 to push the button battery 12 in the plate groove of the detection groove plate 303 to the detection position in the plate groove, and then the detection drive cylinder 304 drives the symmetrical Set the electric shock sensing probe 307 in contact with the two sides of the button battery 12 to detect the electrification performance of the button battery 12, wherein the electric shock sensing probe 307 is connected with the electric signal induction drive of the rotating drive motor I403 of the battery transfer mechanism 4, when the button battery 12 is electrified and detected When qualified, the rotary drive motor I403 receives the power-on signal, and the rotary arm plate 405 is driven to rotate by the rotary drive motor I403, thereby driving the battery adsorption cylinder II406 on the rotary arm plate 405 to rotate to the upper part of the detecti...

Embodiment 3

[0046] Qualified button batteries 12 are conveyed along the battery conveyor belt 501 into the carding tank plate 502, sorted one by one along the conveying and carding tanks of the carding tank plate 502, and finally stop at the output end of the battery conveyor belt 501, and then start the battery The positioning cylinder 610 of the transfer mechanism I6 drives the suction nozzle III 612 to move horizontally by the positioning cylinder 610, thereby adjusting the distance between the suction nozzles III 612 so that the distance between the suction nozzles III 612 is consistent with the distance between the button batteries 12, and then The displacement drive motor 602 drives the drive screw 603 to rotate, thereby driving the suction nozzle III 612 to move to the upper part of the button battery 12 on the output end of the battery conveyor belt 501, and then the vertical displacement cylinder II 614 drives the suction nozzle III 612 to move down, and the suction nozzle III 612 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com