Adhesive composition, adhesive layer and protective film

A technology of adhesive layer and composition, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of reduced inspection, failure to suppress fragments, difficult application, etc., to achieve inspection Excellent performance, excellent laser processability, and the effect of suppressing the generation of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0232] 100 parts by weight of the urethane prepolymer solution A obtained in Production Example 1 in terms of polymer solid content, and 3.4 parts by weight of an isocyanate-based crosslinking agent (trade name "CORONATE HX", manufactured by Tosoh Corp. Co., Ltd.), 0.5 parts by weight in terms of solid content of heat-resistant stabilizer (trade name "Irganox 1010", manufactured by BASF), 10 parts by weight in terms of solid content of silica dispersion liquid (trade name "MEK-EC-2130Y ", manufactured by Nissan Chemical Industry Co., Ltd.) was diluted with ethyl acetate so that the total solid content became 45% by weight, and the adhesive composition (1) was obtained.

[0233] The obtained adhesive composition (1) was applied to a base material made of polyester resin (trade name "T100-75S", thickness 75 μm, manufactured by Mitsubishi Chemical Corporation) so that the thickness after drying was 75 μm. , cured and dried at a drying temperature of 130°C and a drying time of 3 m...

Embodiment 2~6

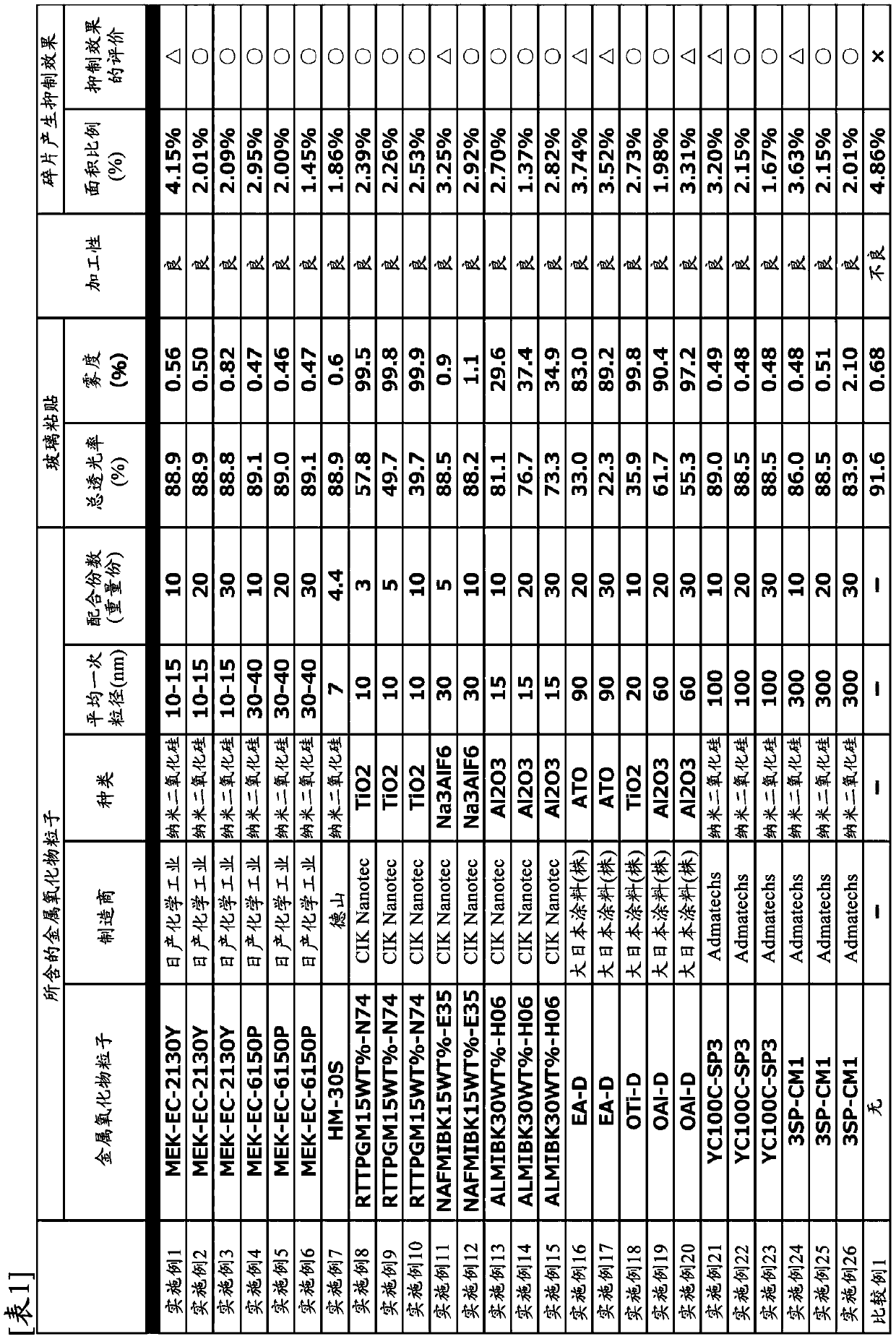

[0237] By the same method as in Example 1, using the adhesive compositions (2) to (6) prepared by setting the type and the number of parts of the silica dispersion as described in Table 1, using the same method as in Example 1, Method got the protective film. Furthermore, evaluation was performed by the same method as in Example 1. The results are shown in Table 1.

Embodiment 7

[0239] Mix 4.4 parts of the urethane prepolymer solution A obtained in Production Example 1 and silica powder (trade name "HM-30S", manufactured by Tokuyama) in terms of polymer solid content to 100 parts by weight, and use a disperser to The mixture was stirred at 1500 rpm for 15 minutes, and the stirred urethane prepolymer solution was filtered through SUS400 mesh. 3.4 parts by weight of an isocyanate-based crosslinking agent (trade name "CORONATE HX", manufactured by Tosoh Corporation) in terms of solid content and 0.5 parts by weight of a heat-resistant stabilizer (trade name "Irganox 1010", manufactured by BASF), and 10 parts by weight of a silica dispersion in terms of solid content (trade name "MEK-EC-2130Y", manufactured by Nissan Chemical Industries, Ltd.) so that the total solid content becomes 45 parts by weight % was diluted with ethyl acetate to obtain an adhesive composition (7).

[0240] Using the obtained adhesive composition (7), a protective film was obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com