Non-chromium passivation liquid used for electrolytic tinning steel plate and use method of non-chromium passivation liquid

A chromium-free passivation and tin-plating technology, which is applied in the field of steel plate surface treatment solution and chromium-free passivation solution, can solve the problem of high manufacturing cost of chromium-free passivation solution, and achieve the effect of no waste of electric energy and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of chromium-free passivation solution that is used for electroplating tin steel plate, described chromium-free passivation solution contains mass concentration and is 5g / L zinc dihydrogen phosphate, 1g / L sodium nitrate, 0.2g / L OP-10 , 1g / L ammonium fluotitanate; the pH value of the chromium-free passivation solution is 1.0; the pH value of the chromium-free passivation solution is adjusted with phosphoric acid.

[0032] The above-mentioned method for using the chromium-free passivation solution for electroplated tin steel plate comprises the following steps:

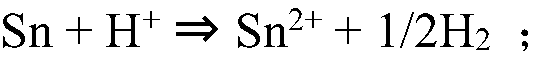

[0033] 1) Electroplating the substrate of the tin-plated steel plate. After the cold-rolled continuous annealed steel plate is washed with alkali and pickled, it is cathodicly electrolyzed in the tin methanesulfonate bath. The bath temperature is 45°C, the tin ion concentration is 18g / L, and the free Acid concentration 50g / L, current density 1.0A / dm 2 , to obtain a coating thickness of 2.8g / m...

Embodiment 2

[0037] Embodiment 2, a kind of chromium-free passivation solution that is used for electroplated tin steel plate, described chromium-free passivation solution contains mass concentration and is 20g / L zinc dihydrogen phosphate, 5g / L sodium nitrate, 2g / L OP-10, 10g / L ammonium fluotitanate; the pH value of the chromium-free passivation solution is 2.0; the pH value of the chromium-free passivation solution is adjusted with phosphoric acid.

[0038] The above-mentioned method for using the chromium-free passivation solution for electroplated tin steel plate comprises the following steps:

[0039] 1) Electroplating the substrate of the tin-plated steel plate. After the cold-rolled continuous annealed steel plate is washed with alkali and pickled, it is cathodicly electrolyzed in the tin methanesulfonate bath. The bath temperature is 45°C, the tin ion concentration is 18g / L, and the free Acid concentration 50g / L, current density 1.0A / dm 2 , to obtain a coating thickness of 2.8g / m ...

Embodiment 3

[0043] Embodiment 3, a kind of chromium-free passivation solution that is used for electroplated tin steel plate, described chromium-free passivation solution contains mass concentration and is 15g / L zinc dihydrogen phosphate, 3g / L sodium nitrate, 1g / L OP-10, 6g / L ammonium fluotitanate; the pH value of the chromium-free passivation solution is 1.5; the pH value of the chromium-free passivation solution is adjusted with phosphoric acid.

[0044] The above-mentioned method for using the chromium-free passivation solution for electroplated tin steel plate comprises the following steps:

[0045] 1) Electroplating the substrate of the tin-plated steel plate. After the cold-rolled continuous annealed steel plate is washed with alkali and pickled, it is cathodicly electrolyzed in the tin methanesulfonate bath. The bath temperature is 45°C, the tin ion concentration is 18g / L, and the free Acid concentration 50g / L, current density 1.0A / dm 2 , to obtain a coating thickness of 2.8g / m 2 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com