Method for reusing industrial waste carbon materials

A carbon material and industrial technology, which is applied in the field of recycling industrial waste carbon materials, can solve the problems of difficult treatment of industrial waste carbon materials, environmental pollution, etc., and achieves the effects of reducing preparation cost, wide selection range and low finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

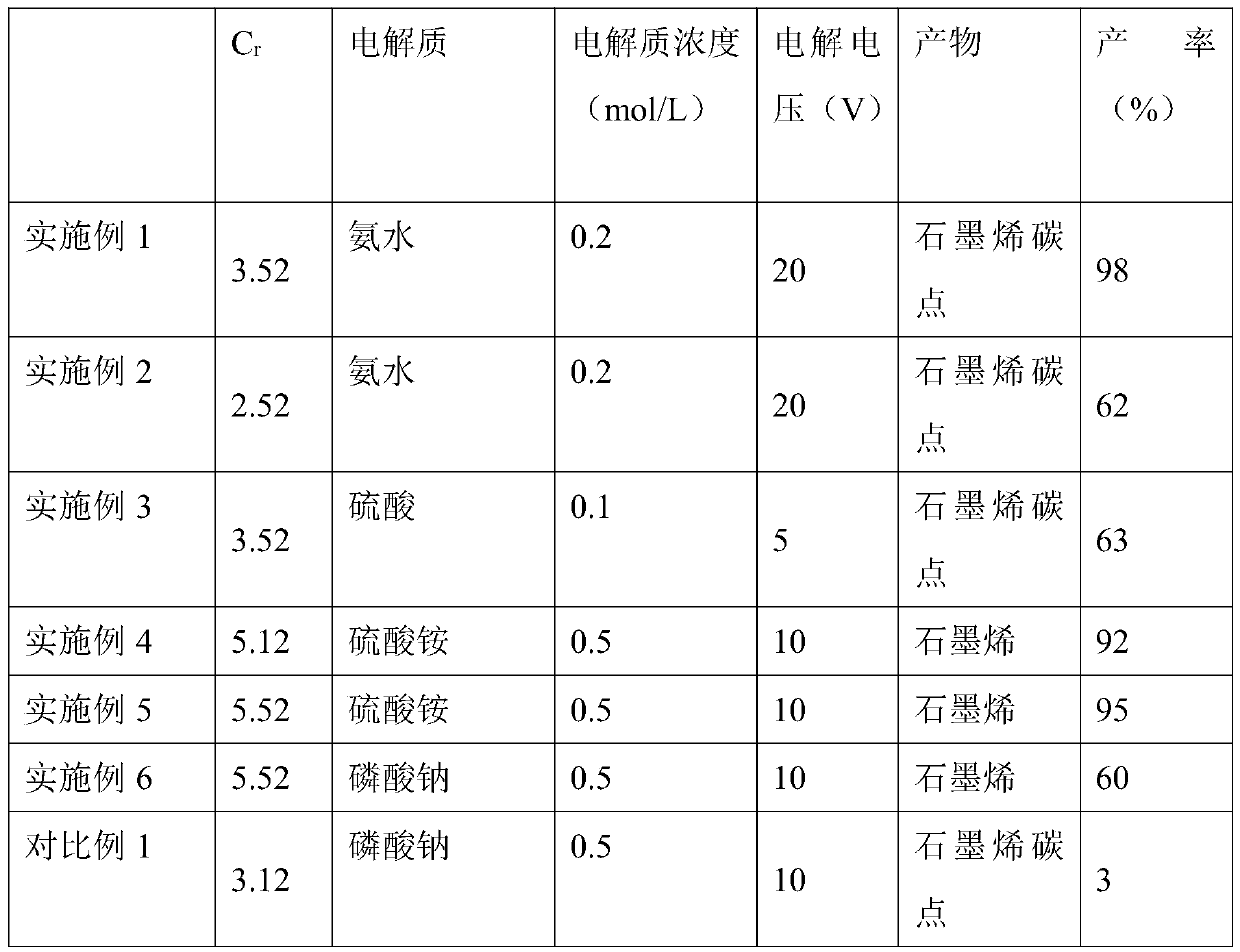

[0019] Select polyimide industrial waste, calculate C r The value is 3.52, which meets the requirements for preparing graphene carbon dots, so the material is made into an electrode, and 0.2mol / L ammonia water is used as the electrolyte, and the electrolysis is performed at a voltage of 20V for 2 hours.

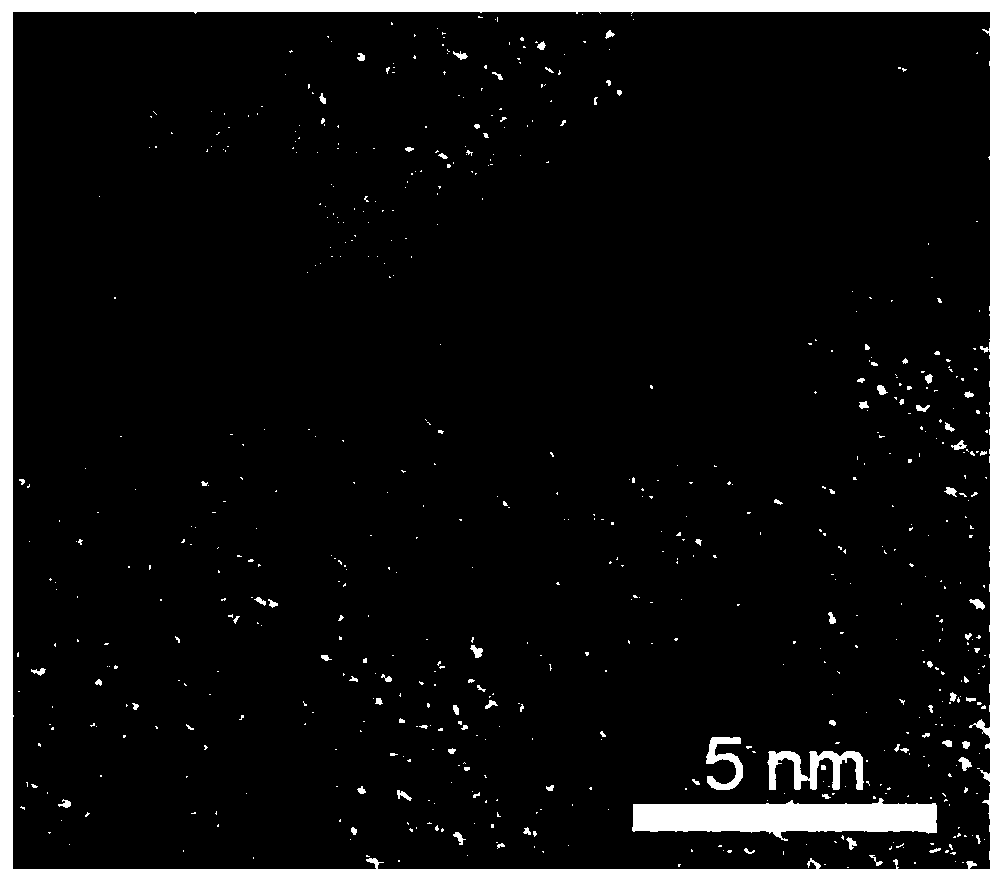

[0020] After the above steps, the obtained graphene carbon dot solution was filtered, and after removing a small amount of filter residue and large sheets of graphene, the yield of the graphene carbon point was calculated to be 98%, and the specific parameters were as shown in Table 1. figure 1 The TEM image of the graphene carbon dots prepared by this method is shown, and the size of the carbon dots is between 3-6nm, which conforms to the definition of carbon dots (below 100nm). At the same time, the carbon dots exhibit a very good lattice structure with a lattice spacing of 0.21 nm.

Embodiment 2

[0022] Select polyimide industrial waste, calculate C r The value is 2.52, which meets the requirements for the preparation of graphene carbon dots, so the material is made into an electrode, and 0.2mol / L ammonia water is used as the electrolyte, and the electrolysis is performed at a voltage of 20V for 2 hours.

[0023] After the above steps, the obtained graphene carbon dot solution was filtered, and after removing a small amount of filter residue and large sheets of graphene, the yield of the graphene carbon dot was calculated to be 62%. The specific parameters are shown in Table 1.

Embodiment 3

[0025] Select polyimide industrial waste, calculate C r The value is 3.52, which meets the requirements for preparing graphene carbon dots, so the material is made into an electrode, and 0.1mol / L sulfuric acid is used as the electrolyte, and the electrolysis is performed at a voltage of 5V for 2 hours.

[0026] After the above steps, the obtained graphene carbon dot solution was filtered, and after removing a small amount of filter residue and large sheets of graphene, the yield of the graphene carbon dot was calculated to be 63%. The specific parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com