Anti-collision guardrail with buffering function

An anti-collision guardrail and functional technology, applied in the direction of roads, road safety devices, roads, etc., can solve the problems of easily damaged guardrails, vehicle rollover, and inability to release impact energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

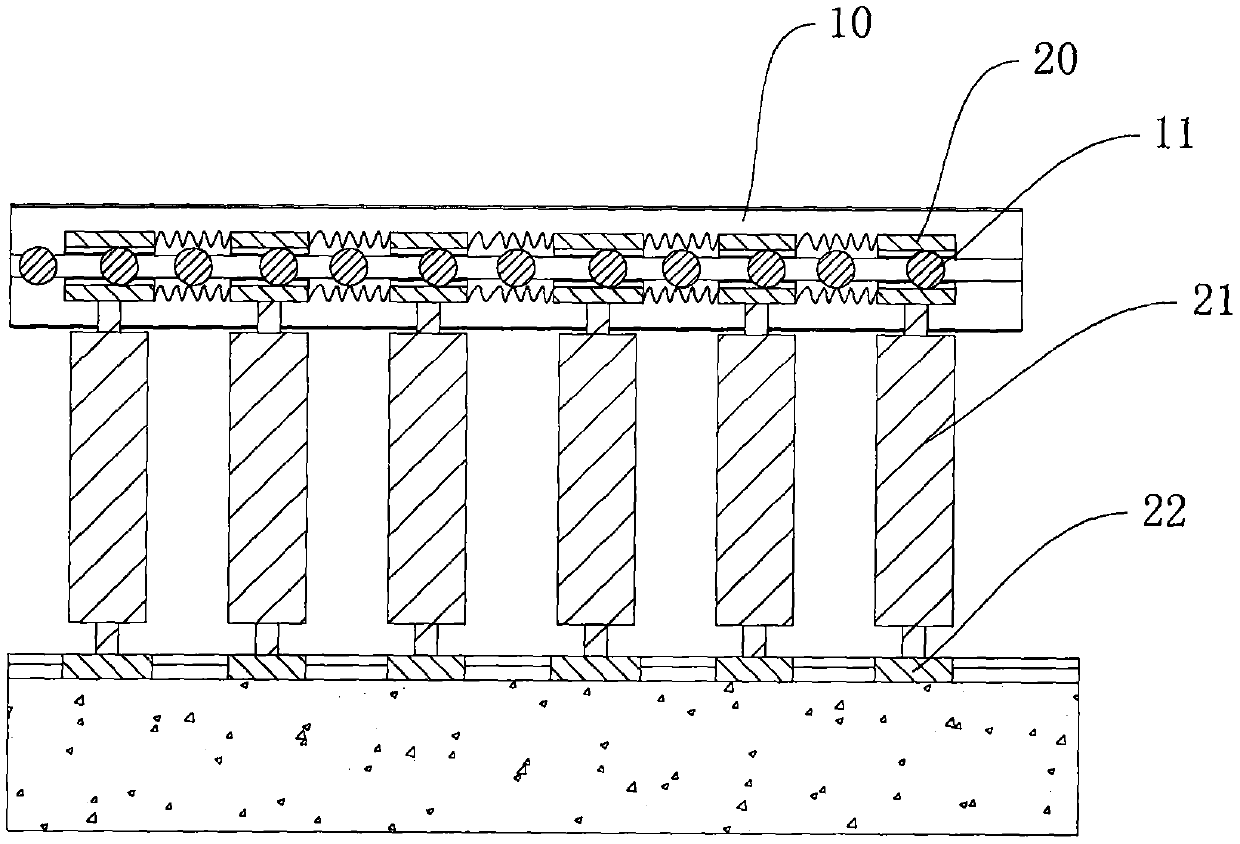

[0032] like figure 1 As shown, an embodiment of the present invention provides a bumper barrier with a buffer function, including a wave barrier 10, and further includes:

[0033] The primary buffer mechanism includes a plurality of rollers 21, a guide block 20 arranged at the upper end of the roller 21 and corresponding to the roller 21 one-to-one, an upper support plate 22 arranged at the lower end of the roller 21 and corresponding to the roller 21 one-to-one, and rotatably arranged on the Several guide wheels 11 on the wave guardrail 10, the roller 21 can rotate relative to the guide block 20 and the upper support plate 22, the upper support plate 22 is slidably arranged on the installation foundation, the guide block 20 is provided with a guide groove, and the guide groove is C-shaped Structure, the guide wheel 11 is connected to the wave guardrail 10 through a rotating shaft, the guide wheel 11 is located in the guide groove, the rotating shaft extends out of the guide g...

Embodiment 2

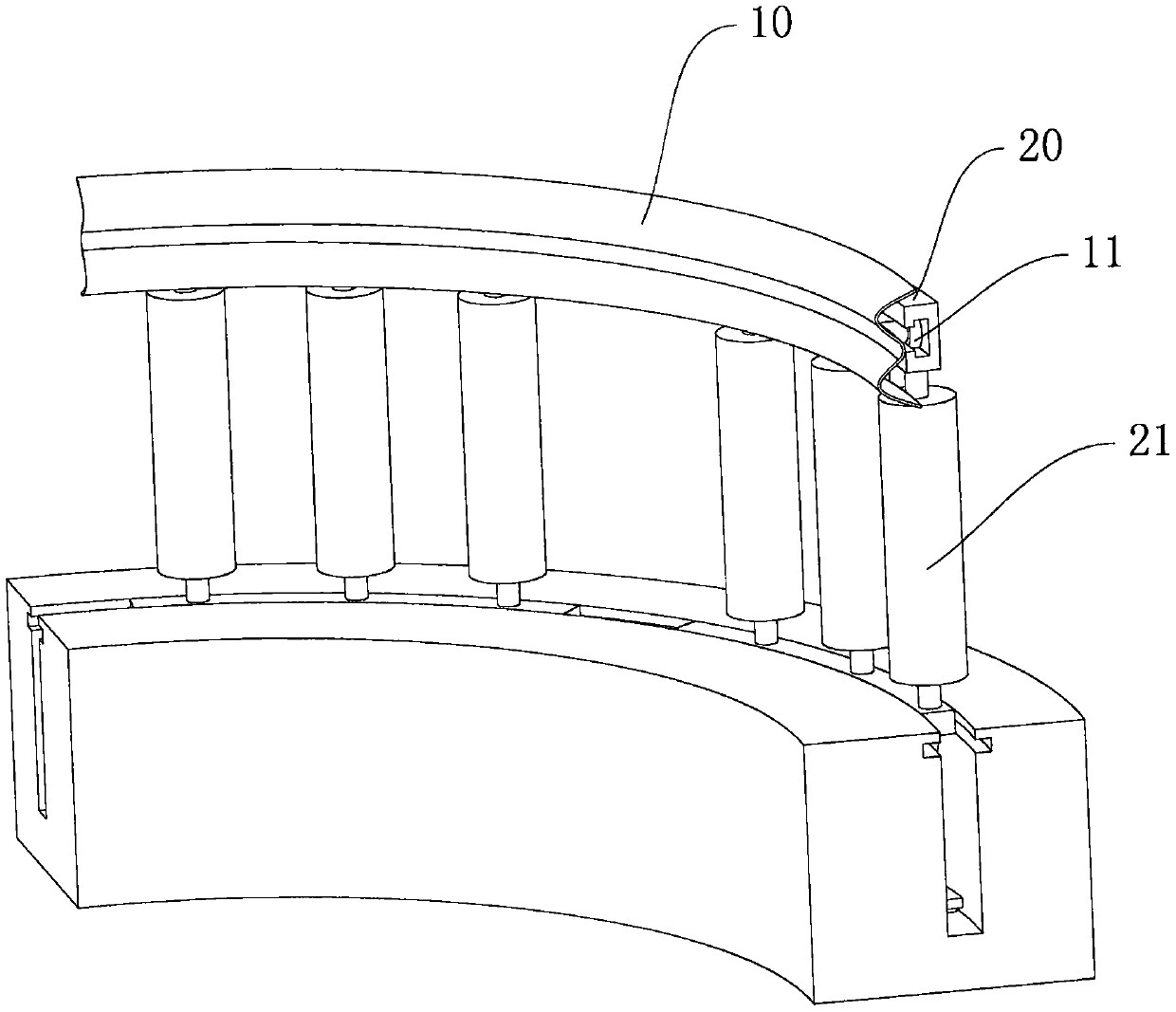

[0036] On the basis of Example 1, as Figure 2 to Figure 8 As shown, this embodiment also includes a secondary buffer mechanism, such as figure 2As shown, it includes a lower support plate 25, a telescopic mechanism and two buffer springs 26, the upper support plate 22 corresponds to the lower support plate 25 one-to-one, and the telescopic mechanism includes a first connecting rod 23 and a second connecting rod 24, the first connecting rod 23 and the second connecting rod 24. The rod 23 and the second connecting rod 24 are crossed. The first connecting rod 23 is provided with a first sliding groove 231, the second connecting rod 24 is provided with a second sliding groove 241, the first sliding groove 231 and the second sliding groove 241. They are connected by a pin shaft, the pin shaft is slidably arranged in the first chute 231 and the second chute 241, the lower support plate 25 is provided with a support block 251, and the support block 251 is provided with a vacant chu...

Embodiment 3

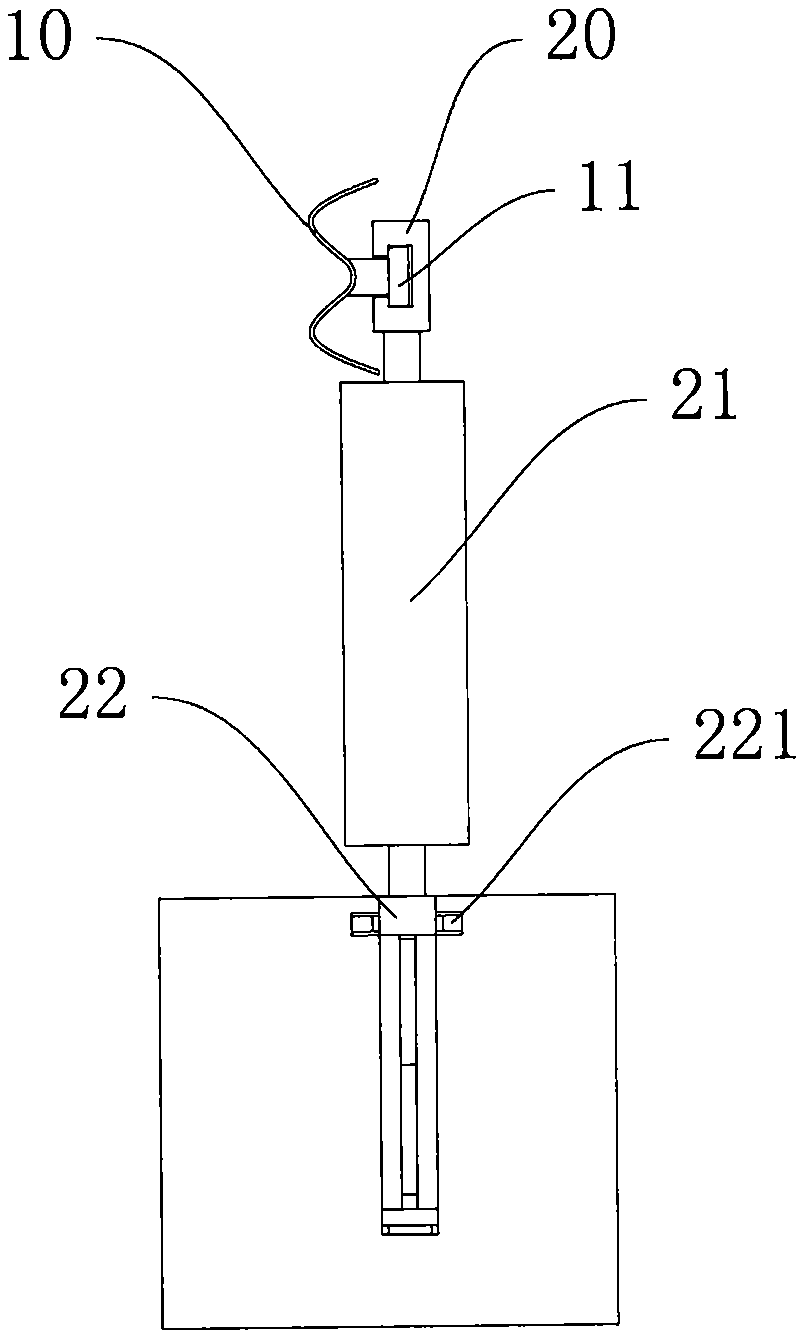

[0040] like Figure 9 and Figure 10 As shown, several baffles 211 are arranged on the drum 21. When the drum 21 rotates, the baffles 211 are driven to rotate. turn to.

[0041] Wherein, the cross section of the baffle 211 is in a triangular structure that gradually converges in the direction away from the drum 21 .

[0042] When the vehicle hits, it drives the drum 21 to rotate, and when the drum 21 rotates, it drives the baffle 211 to rotate. When the first drum 21 rotates, it drives the baffle 211 to rotate. Taking the clockwise direction as an example, the baffle 211 drives the adjacent other A roller 21 rotates in the opposite direction, that is, counterclockwise. When the baffle plate 211 hits the adjacent baffle plate 211, it will generate an impact and consume a part of the energy, and when the vehicle continues to move, it will hit the next adjacent roller. The baffle 211 on the 21, and at this time, the rotation of the baffle 211 is opposite to the moving directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com