Autorotation type sunflower seed stripper

A technology for sunflower seeds and strippers, applied in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve problems such as arm injury, arm burden, low efficiency, etc., and achieve the effects of convenient operation, improved stripping efficiency, and reduced safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

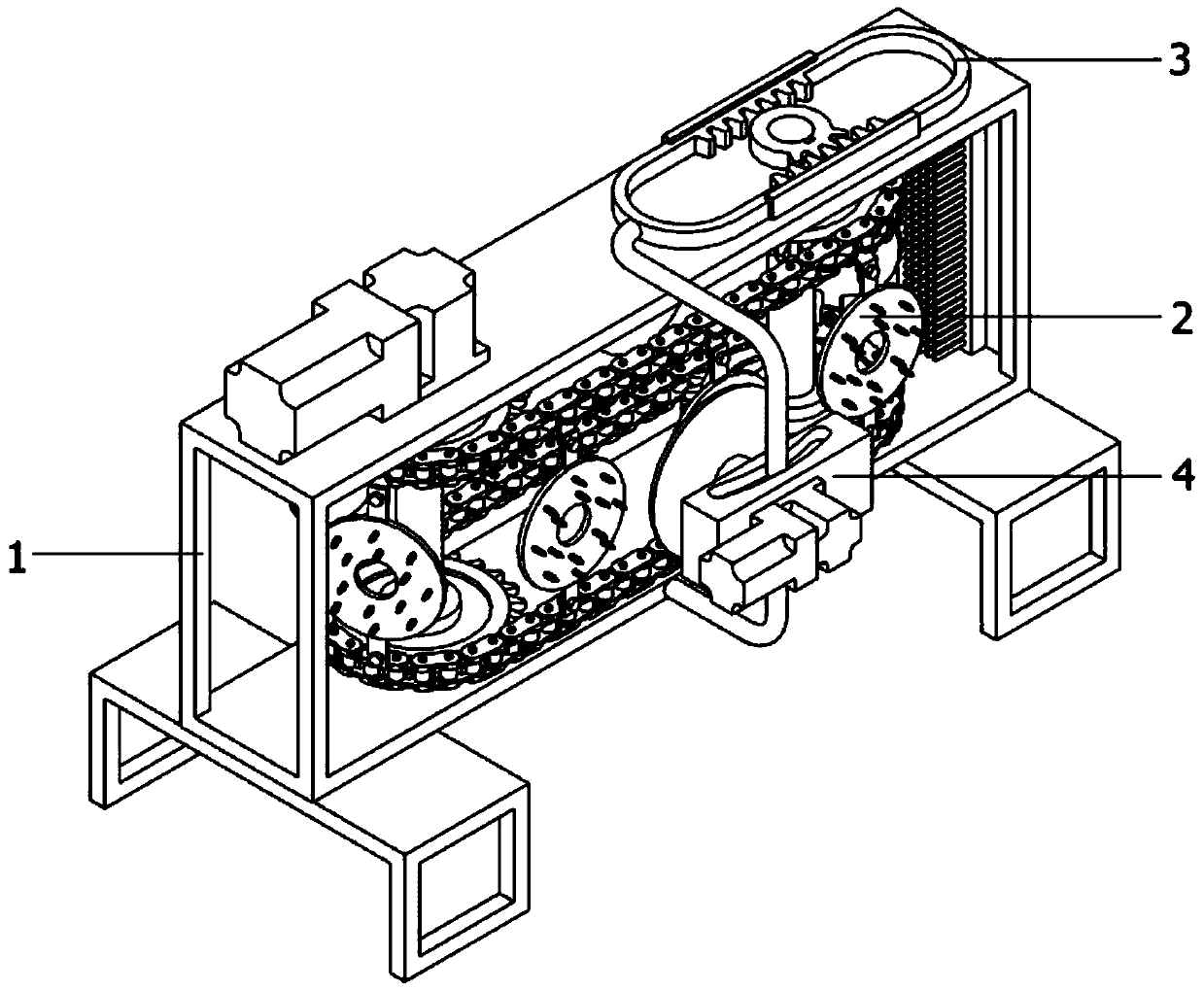

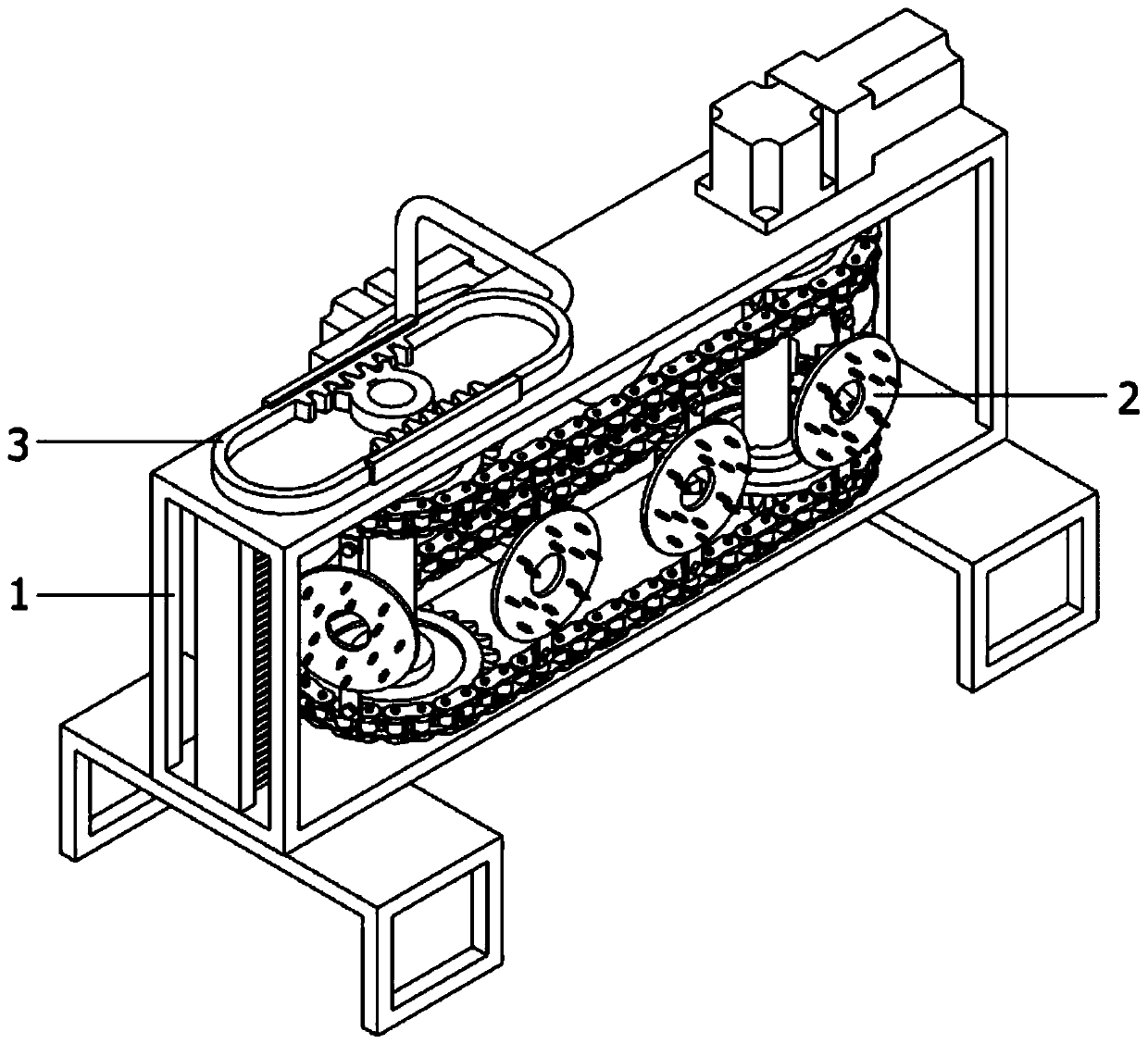

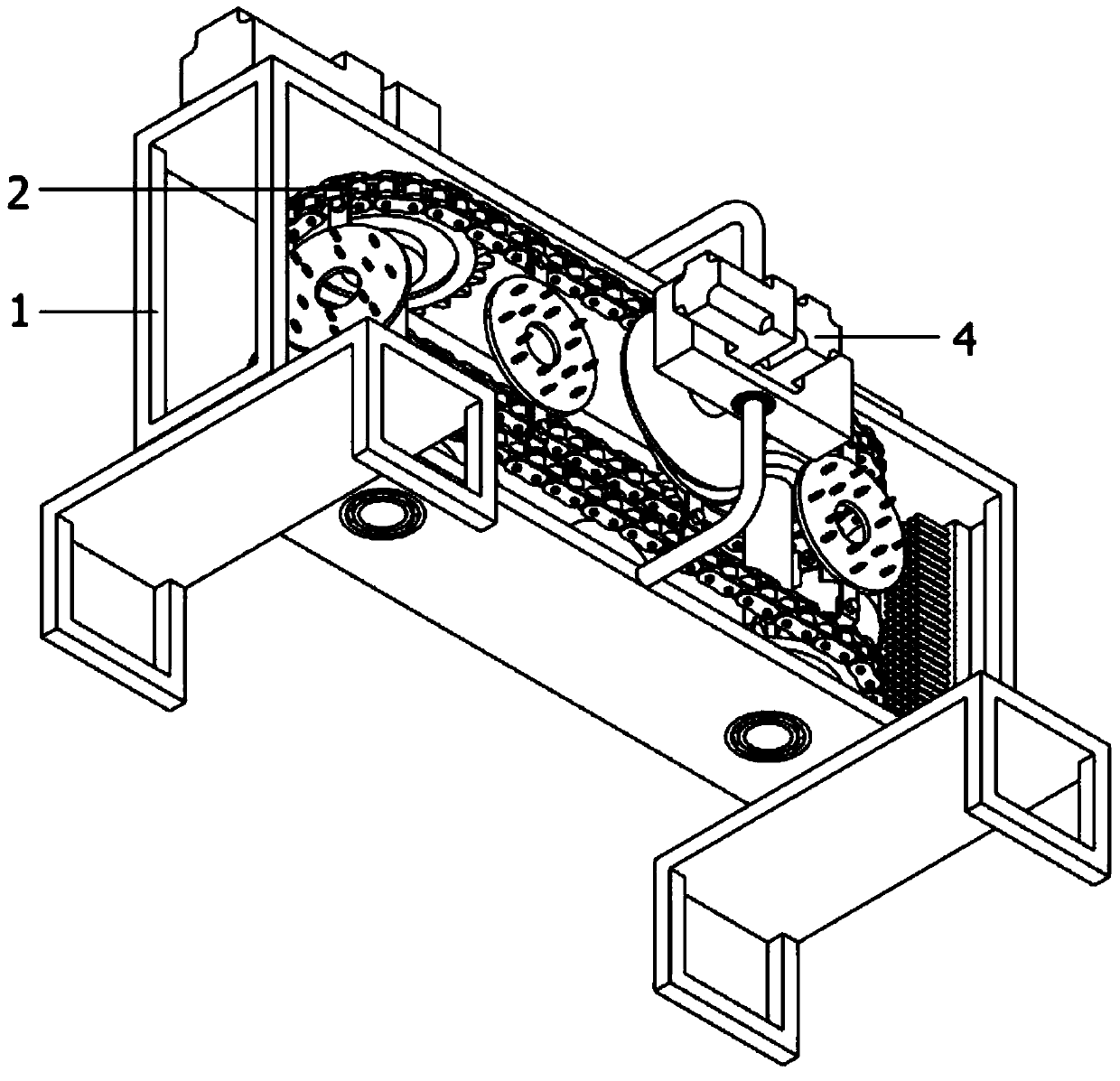

[0044] as attached figure 1 To attach Figure 17 Shown:

[0045] The present invention provides a sunflower seed self-rotating detacher, including: a frame body 1, a conveying mechanism 2 is installed in the inner frame of the frame body 1, and the frame body 1 includes an upper rectangular plate 101, a lower rectangular plate 102, a connecting rod 103, and a bearing A104 , L-shaped limit bar 105, L-shaped bent round rod 106, bearing B107, rectangular brush plate 108, brush assembly 109, support plate frame 1010, and a lower plate consistent with its structure is arranged directly under the upper rectangular plate 101. Rectangular plate 102, and the corners of the four corners of the bottom surface of the upper rectangular plate 101 and the four corners of the top surface of the lower rectangular plate 102 are connected by a connecting rod 103, the left and right sides of the upper rectangular plate 101 and the lower rectangular plate 102 There is a round hole on both sides,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com