Extinguishing method special for high-voltage switch cabinets

A high-voltage switchgear and cabinet body technology, which is applied in the field of fire extinguishing for high-voltage switchgear, can solve problems such as the difficulty of deploying the suspended fire extinguishing system, the lack of fire extinguishing methods for high-voltage switchgear, and the inability to realize fixed-point switchgear fire extinguishing, etc., to achieve rapid and effective fire control , reduce the temperature and shorten the fire extinguishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

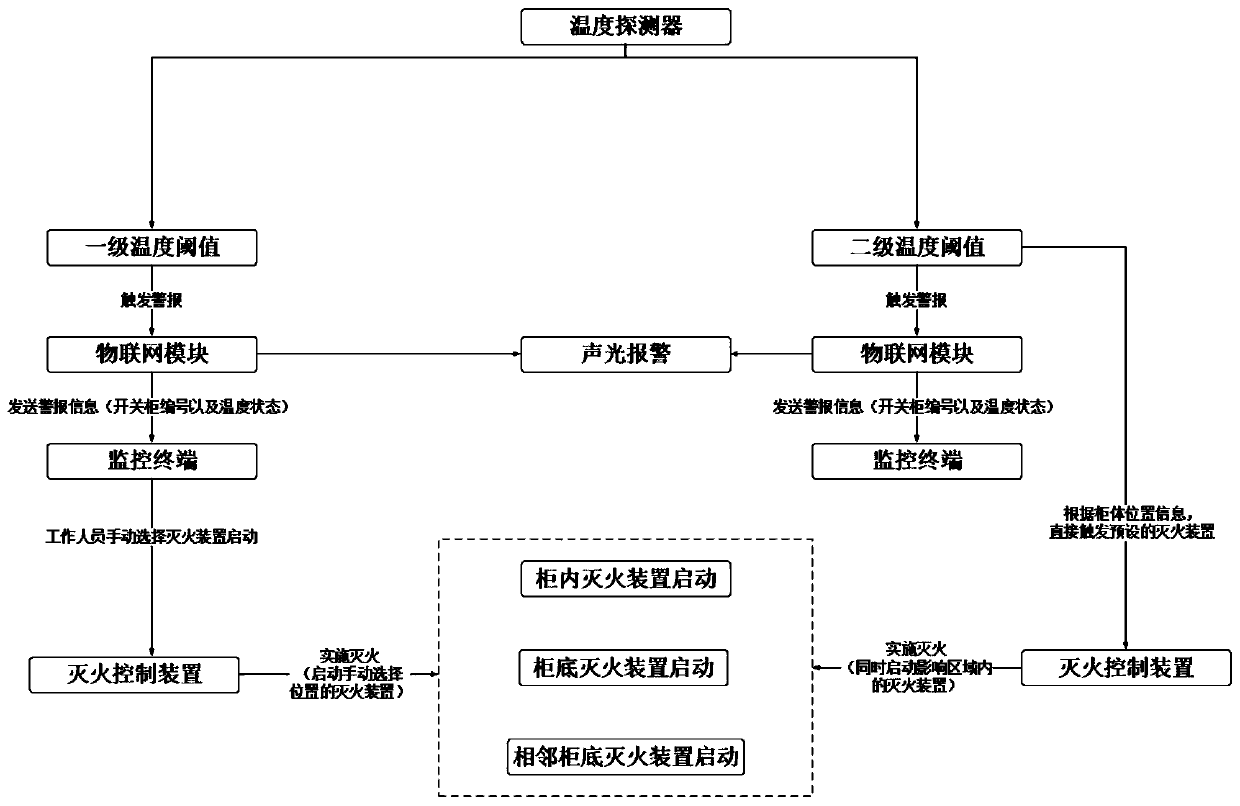

[0026] Such as figure 1 As shown, a special fire extinguishing method for a high-voltage switchgear of the present invention comprises the following steps:

[0027] Step S10, numbering the high-voltage switch cabinets of the high-voltage substation sequentially according to their positions, and dividing them into the above-ground high-voltage switch cabinet area, the cable passage area at the bottom of the adjacent cabinet body, and the underground cable area;

[0028] Step S20, install clean gas fire extinguishing spraying devices on the three areas of each high-voltage switchgear, wherein the three sprinklers are respectively located in the high-voltage switchgear, the cable at the bottom of the cabinet, and the cable channel at the bottom of the adjacent cabinet;

[0029] Step S30, when the temperature in the cabinet reaches the first critical v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com