Honeycomb wheel core structure in zeolite wheel

A technology of zeolite runner and honeycomb wheel, which is used in gas treatment, dispersed particle separation, membrane technology and other directions, can solve the problems of low adsorption efficiency, cannot be too fast, and desorption is not complete enough, so as to improve the concentration ratio and improve the economy. Benefit, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

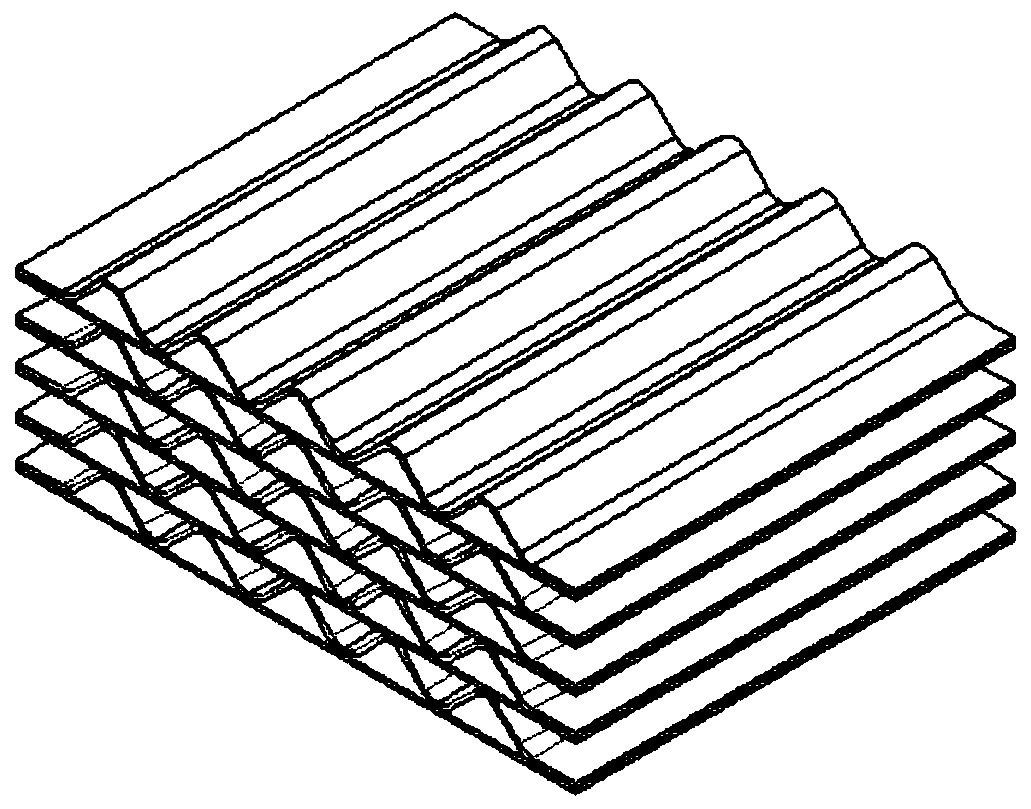

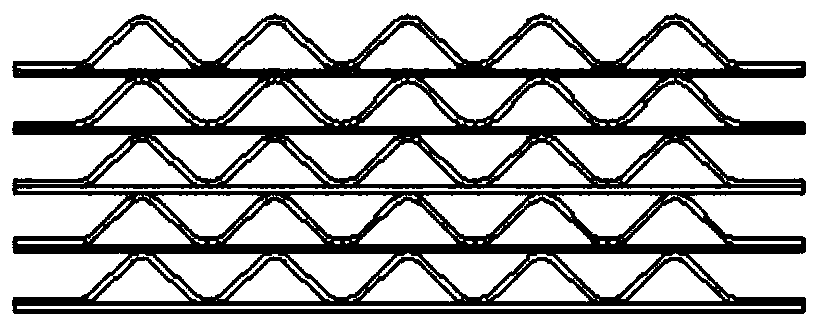

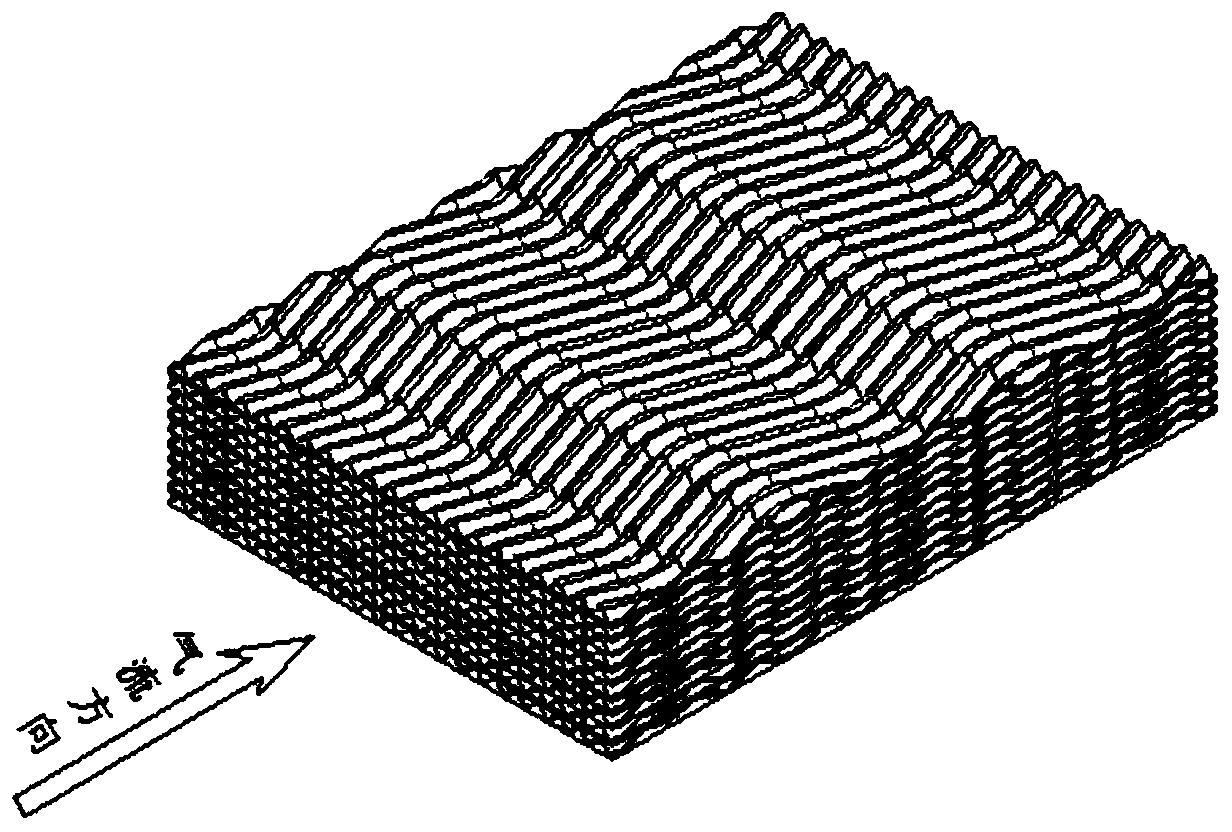

[0025] A honeycomb core structure in a zeolite runner according to the present invention includes a honeycomb core and a number of channels opened in the honeycomb core, and the channels are curved channels. The main body of the channel presents a wavy structure curved up and down. The wave-shaped structure of the channel has a plurality of waves. The distance between the crest and trough of the waveform in the vertical direction is 1-3 times the height of the channel.

[0026] All the channels are evenly distributed in the honeycomb wheel core.

[0027] image 3 Based on the schematic diagram of the curved channel of the honeycomb wheel core, this figure is not the form of the final product, it is only for illustration.

[0028] In the production of actual products, the relationship between the pressure drop and efficiency of the airflow handled by the wheel core and the concentration ratio will be taken into account. The design of the curved channel has too many waves, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com