a coating device

A technology of equipment and coatings, applied in the field of environmental protection equipment, can solve problems such as the influence of the anti-corrosion performance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

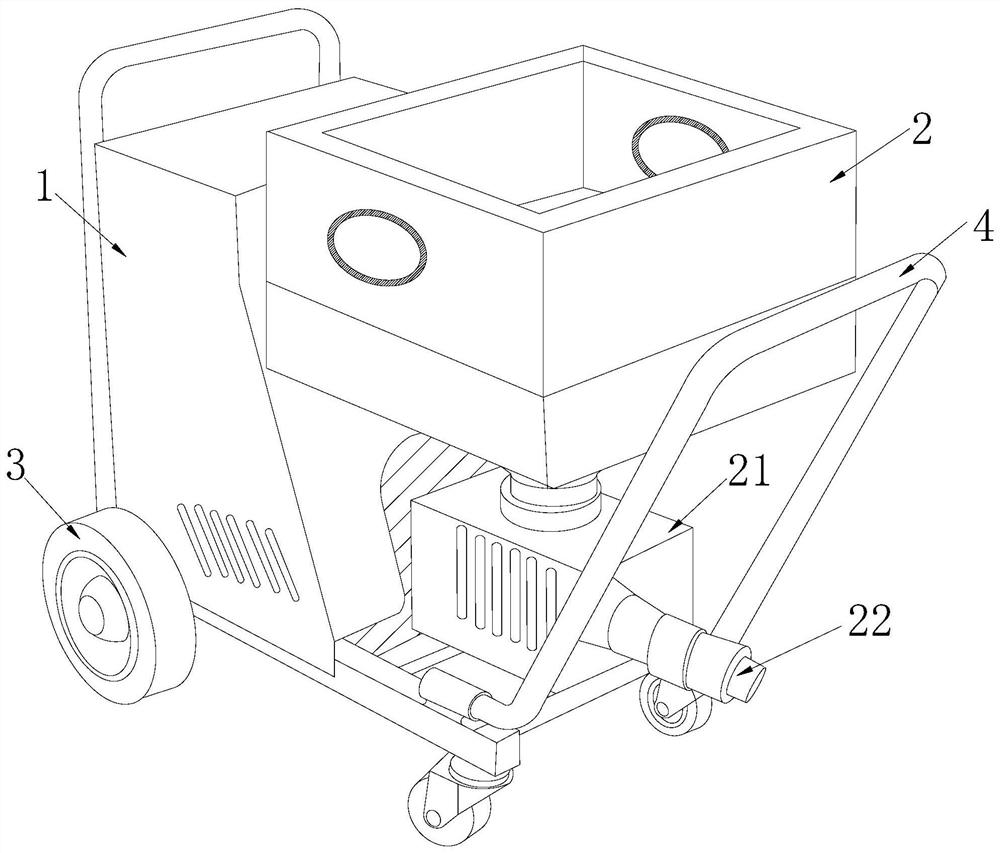

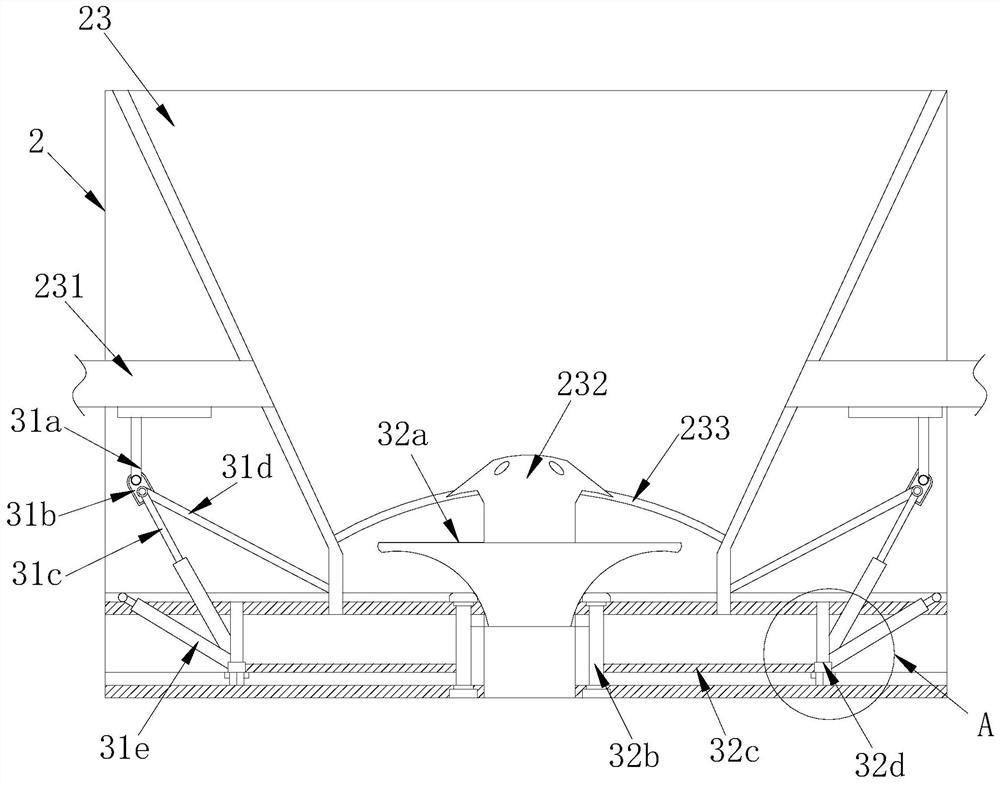

[0025] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of coating equipment, and its structure comprises control cabinet 1, dispersing box 2, moving wheel 3, handle 4, is made up of press 21, discharge port 22 and dispersing chamber 23 in described dispersing box 2, Described mobile wheel 3 is provided with four, and wherein has brake disc in the mobile wheel 3 that is close to discharging opening 22 sides, and described handle 4 and control cabinet 1, press machine 21 are all installed on the frame, and described The press 21 is provided with a discharge port 22, the bottom end of the dispersion box 2 is set together with the press 21, and the dispersion chamber 23 is funnel-shaped.

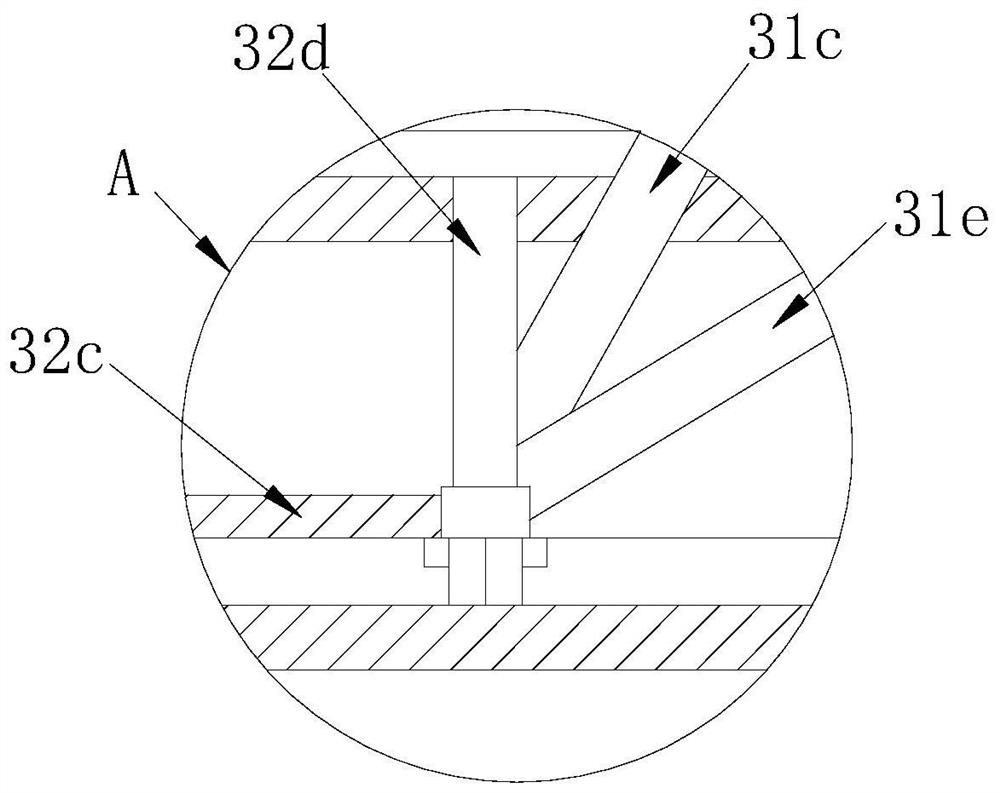

[0026] The inner bottom end of the dispersion chamber 23 is equipped with an agitator 232 and a carrying plate 233, the agitator 232 is fixed on the central raised position of the carrying plate 233, and the carrying plate 233 is made of an elastic material into an arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com