A multi-nozzle nozzle droplet spraying device

A technology of droplet spraying and multi-nozzle, which is applied in the direction of spraying devices and spraying devices with movable outlets, etc. It can solve the problems of increasing the load of droplet spraying motors, the inability to realize multi-material printing, and the reduction of effective spraying space. It is difficult to guarantee the accuracy of the injection position, realize the effect of multi-material injection, and simplify the difficulty of finding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

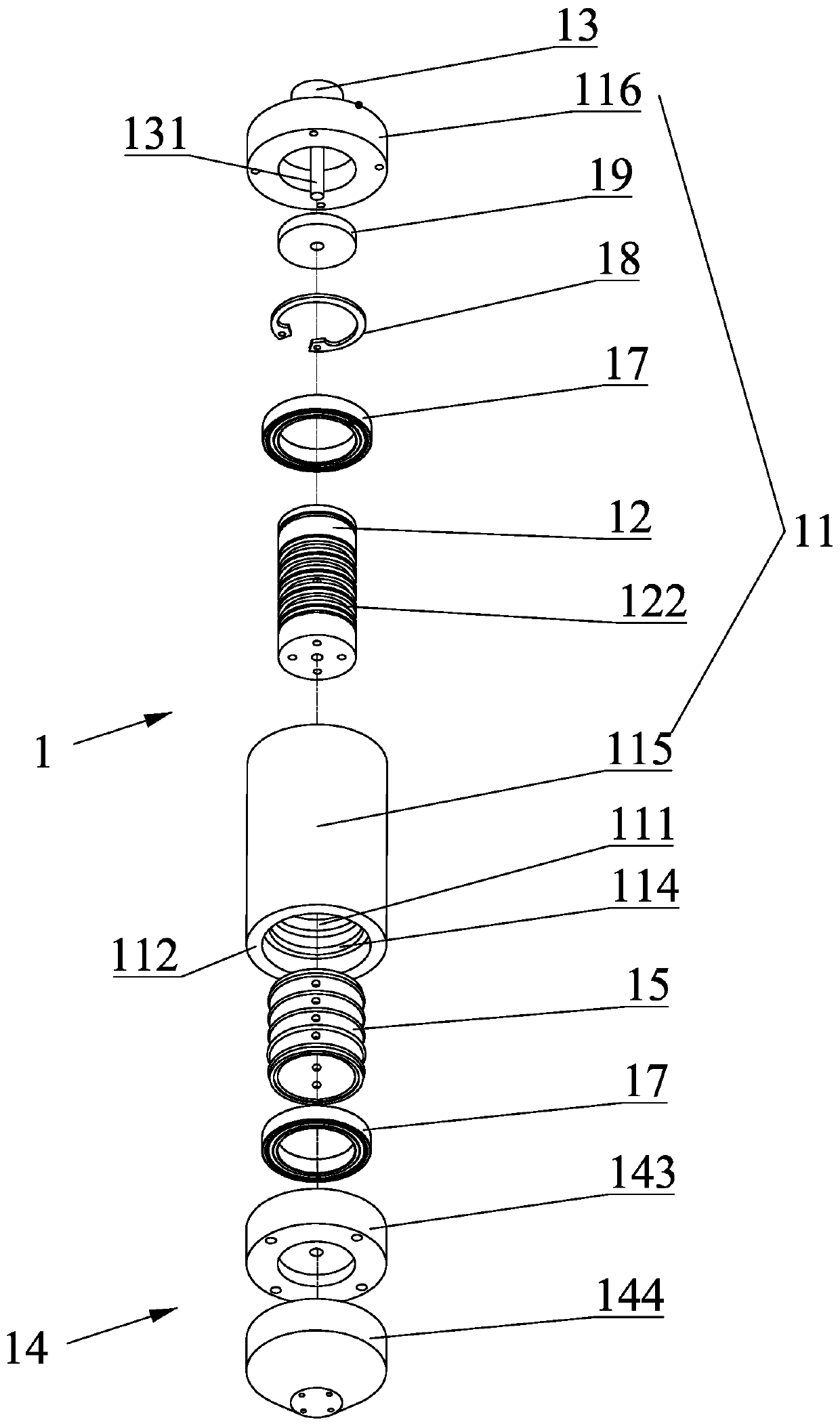

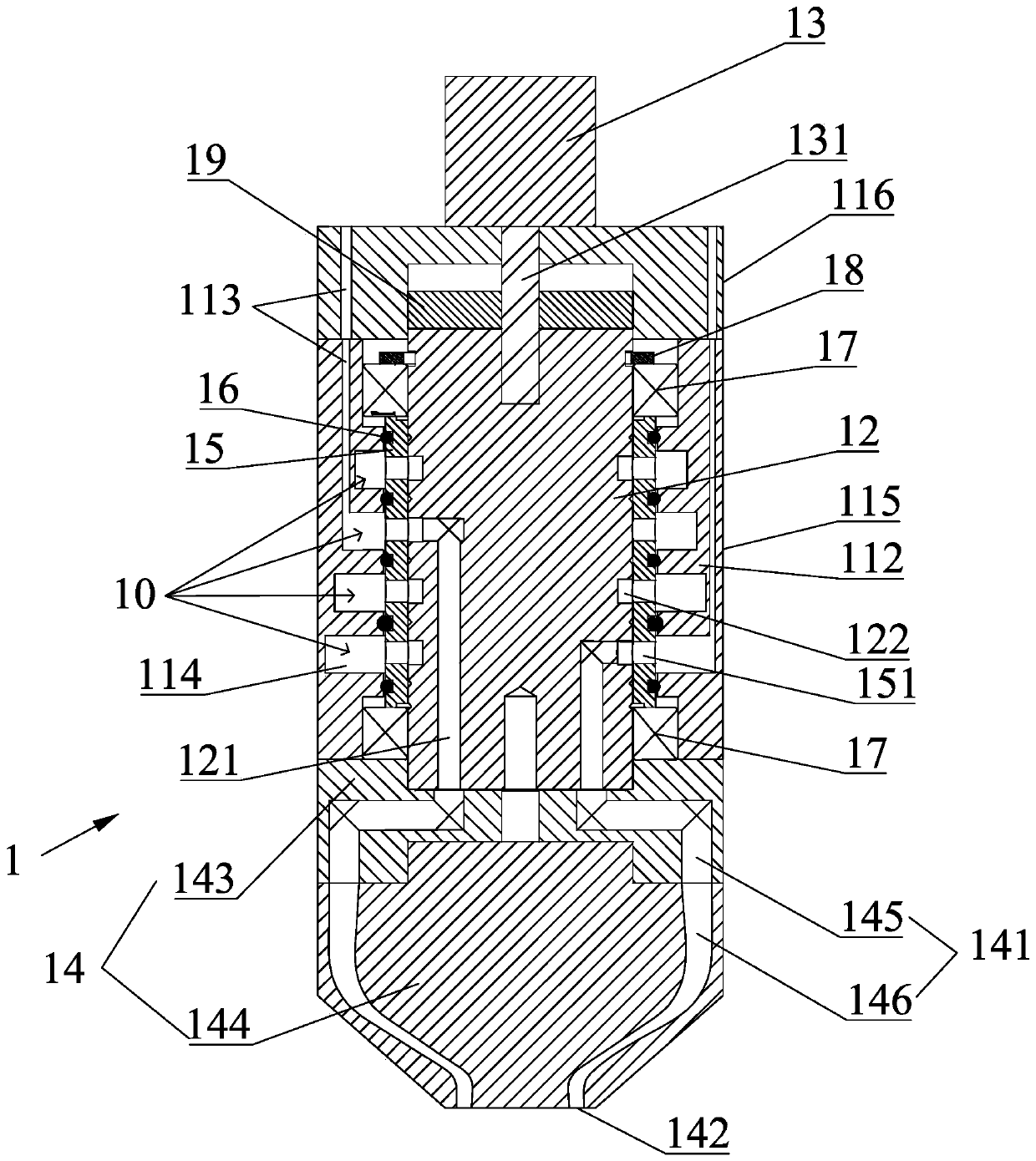

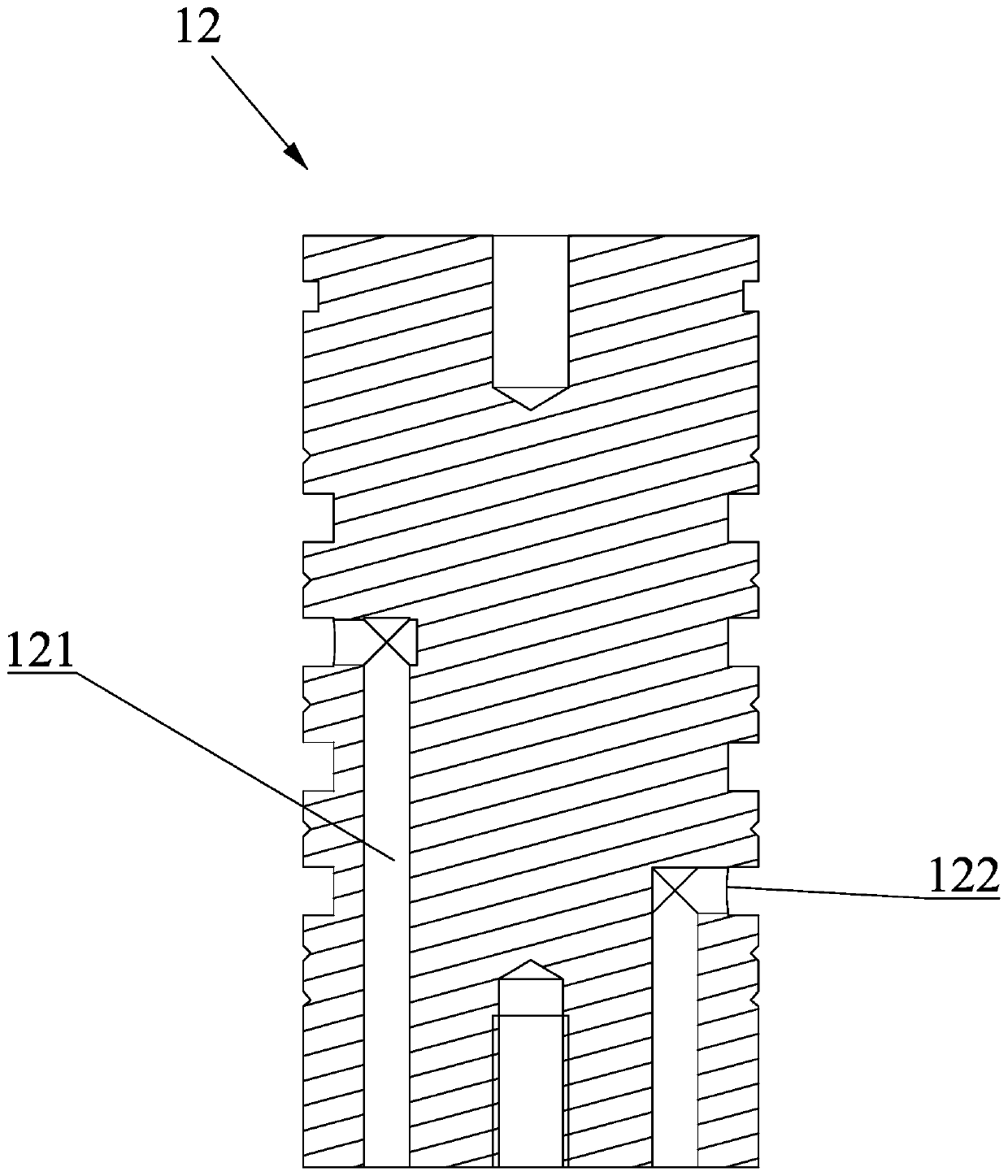

[0044] Disclosed in the present invention is a multi-nozzle nozzle droplet ejection device, such as Figure 7 Shown is a preferred embodiment of the droplet ejection device. The droplet spraying equipment includes a multi-nozzle nozzle 1, a workbench 2, an XY-axis moving device 3, a Z-axis moving device 4, a nozzle rotating device 5, a solution tank 6, a circulation system 7, a cleaning liquid recovery device 8, a support frame 9 and Control System. in:

[0045] The multi-nozzle shower head 1 is the key technology of the present invention, which is installed on the Z-axis moving device 4, and the Z-axis moving device 4 can drive the multi-nozzle shower head 1 to move in the Z direction. The multi-nozzle spray head 1 is located above the workbench 2, and is used to spray micro-spray material onto the workbench 2 for micro-spray prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com