Transformer substation knife switch laser cleaning system

A laser cleaning and substation technology, applied in the field of laser cleaning systems, can solve the problems of cleaning dead angles, high labor intensity, and low efficiency, and achieve the effects of avoiding cleaning dead angles, reducing labor intensity, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

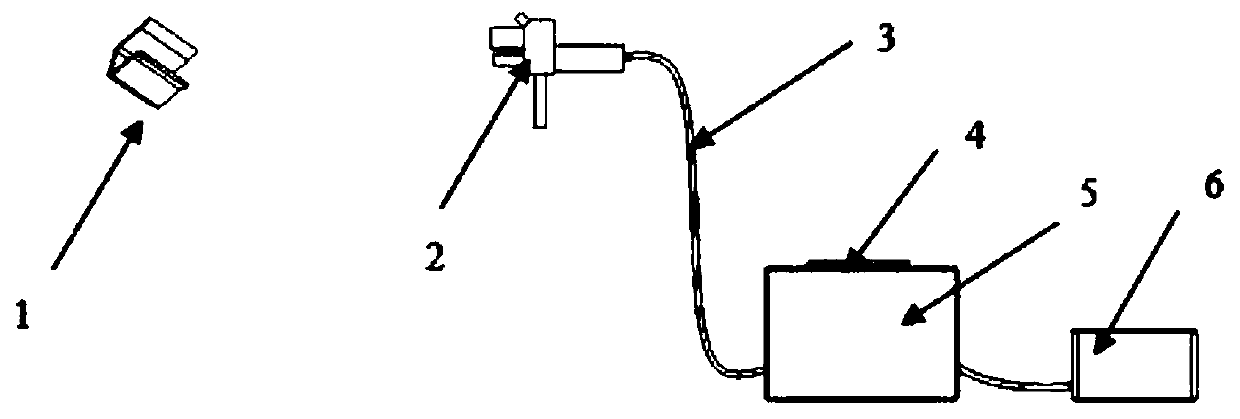

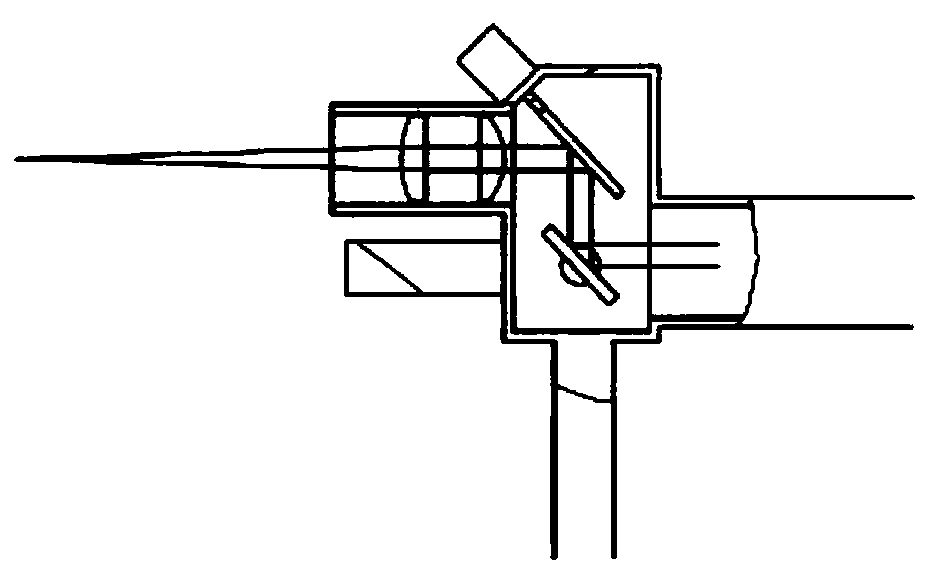

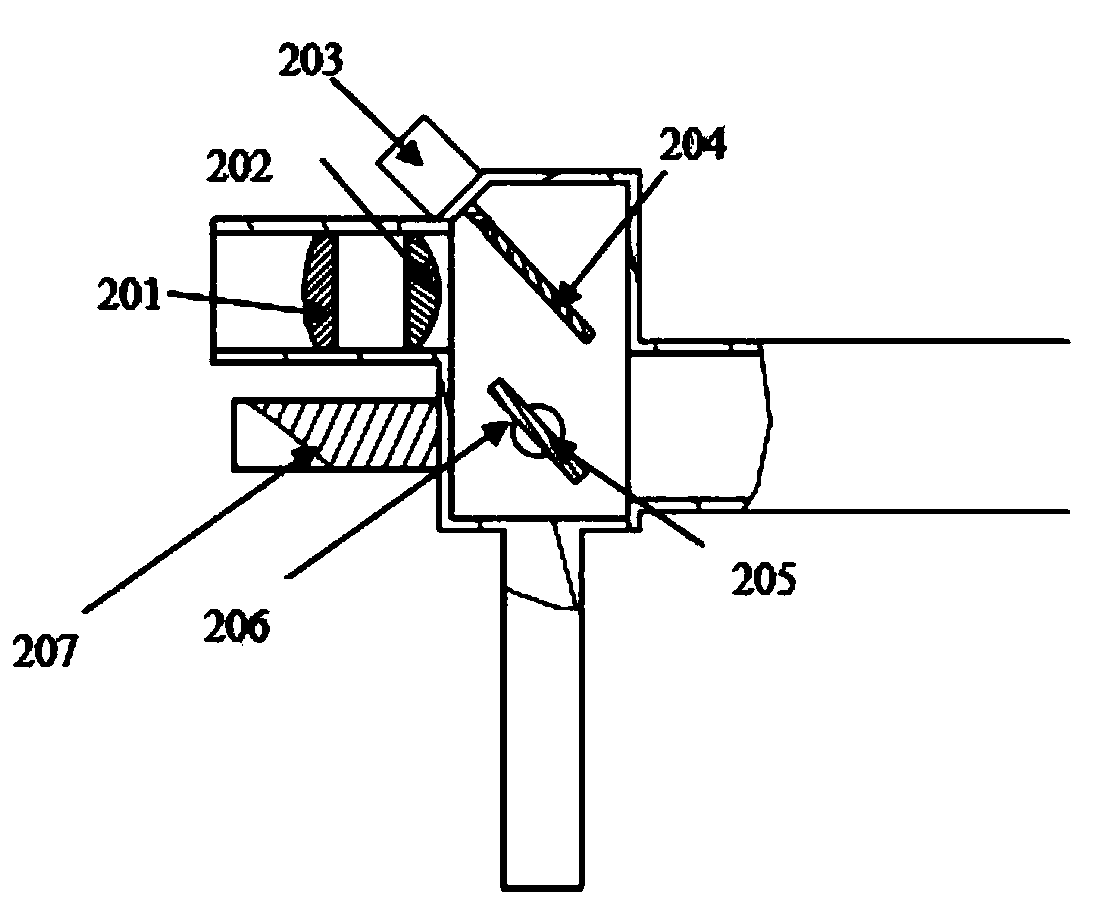

[0016] A laser cleaning system for substation knife switches, such as figure 1 As shown, it includes a laser generator 5 and a laser cleaning head 2 connected to the laser generator. The inside of the laser cleaning head is a cavity, one end is provided with an entrance, and the other end is provided with an exit port. There are first vibrating mirror 205 and second vibrating mirror 204 used to reflect the laser light from the incident angle to the exiting angle; the exit port is provided with a first lens 202 and a second lens 201 vertically parallel to each other. The second lens is used to focus the laser light reflected by the first and second vibrating mirrors. The laser generator 5 is powered by a power module 6, and the power module is preferably a lithium battery.

[0017] In the specific work, the laser light from the laser generator is transmitted to the entrance, and is emitted from the exit through the first and second lens reflection ports set inside the laser cl...

Embodiment 2

[0021] In addition to relying on the hand-held laser cleaning head to clean the contact surface of the knife gate, the laser cleaning head can also be fixed, and the angle of the laser beam can be adjusted by changing the angle of the first and second vibrating mirrors, so as to achieve the same effect as manual small swing laser. Cleaning the head does the same.

[0022] In this embodiment, the first and second vibrating mirrors are rotatably fixed in the cavity; the first and second vibrating mirrors are respectively connected with a first motor 206 and a second motor 203, and the first , The second motor is controlled by the controller 4 .

[0023] Under the action of the first motor, the first oscillating mirror achieves the effect of moving the outgoing laser up and down by changing the angle between it and the incident laser light; The included angle with the laser reflected by the first vibrating mirror achieves the effect of moving the outgoing laser left and right. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com