A Control Method for Preventing the Overflow of the Emulsion Return Oil Tank of the Continuous Rolling Mill

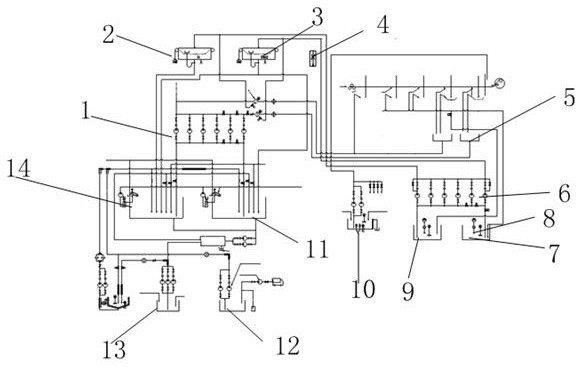

A control method and oil return tank technology, which is applied in the field of liquid level control and cold rolling electrical automation, and can solve problems such as rapid liquid level changes, water droplet adhesion, and measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is carried out as follows transformation in the emulsion system of acid tandem rolling mill of Shanxi Taigang Stainless Steel Co., Ltd.

[0028] 1. Replace the original XPS15FXZ+MR100 ultrasonic level gauge with VEGAFLEX83 rod radar level gauge;

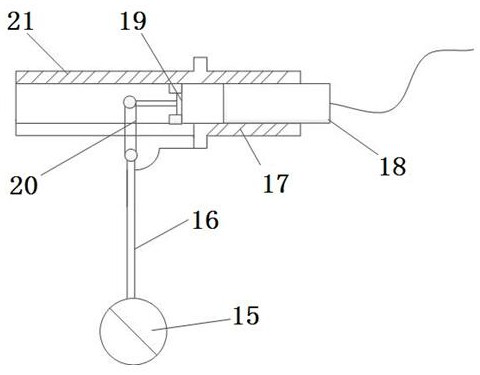

[0029] 2. A fixed tank is installed on the top of the oil return tank of the emulsion system of the rolling mill, and a liquid level control device is installed in the fixed tank.

[0030] figure 2 As shown, the liquid level control device is composed of a float 15, a proximity switch 18, and an induction head 19. The float 15 is welded on one end of the connecting rod 16, and the other end of the connecting rod 16 is hinged with a shrapnel 20. The shrapnel 20 is connected to the sensing head 19, and the proximity switch 18 It is fixedly installed on the mounting frame 21; the distance between the sensor head 19 and the proximity switch 18 is at least 1.5 cm, and the proximity switch 18 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com