Method for measuring rotatable workpiece and using base coordinates in industrial robot system

A technology for industrial robots and rotating workpieces. It is applied in manipulators, manufacturing tools, and comprehensive factory control. It can solve problems such as cumbersome operations, inability to display the coordinate data of the turntable base, and difficulties in offline programming of robots, and achieve the goal of simplifying steps and the required time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

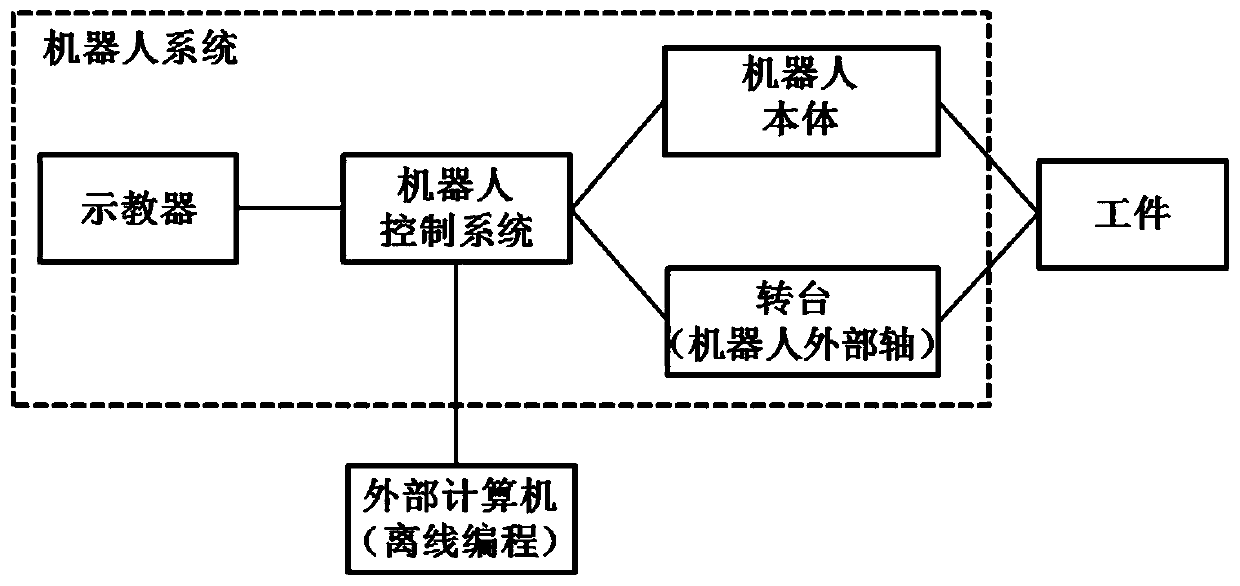

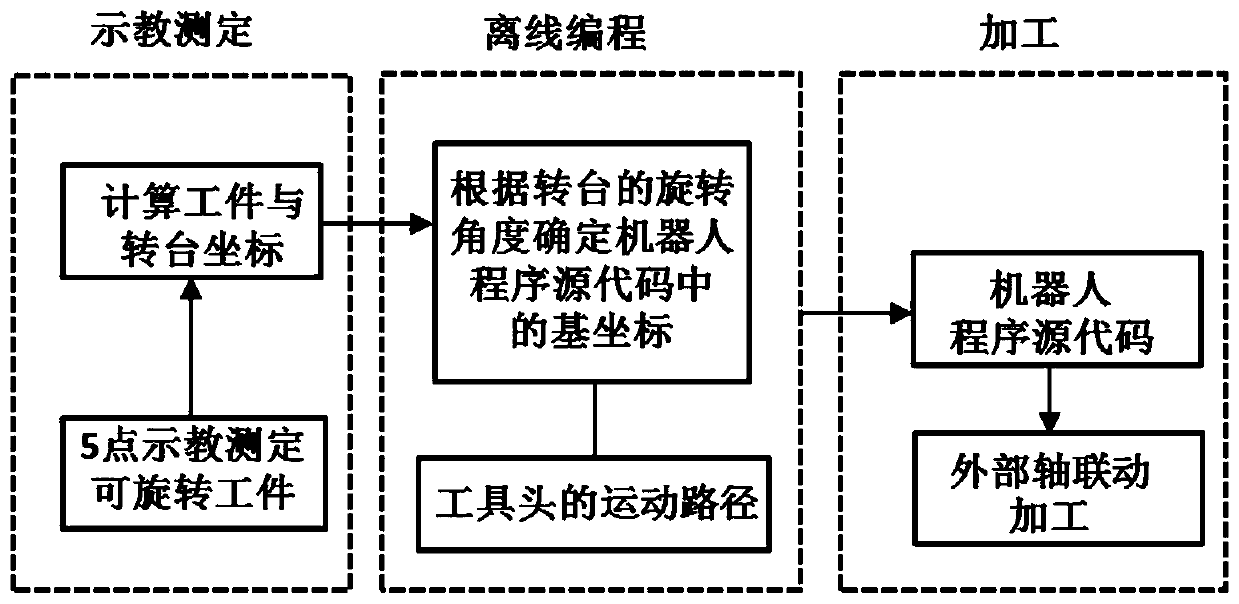

[0064] The industrial robot system used in the present invention is as figure 1 As shown, it includes the robot body, robot control system, turntable (robot external axis), and teaching device; the robot system combines with an external computer to realize workpiece measurement. The overall workflow of the inventive method is as figure 2 Shown, including teaching measurement, off-line programming and processing.

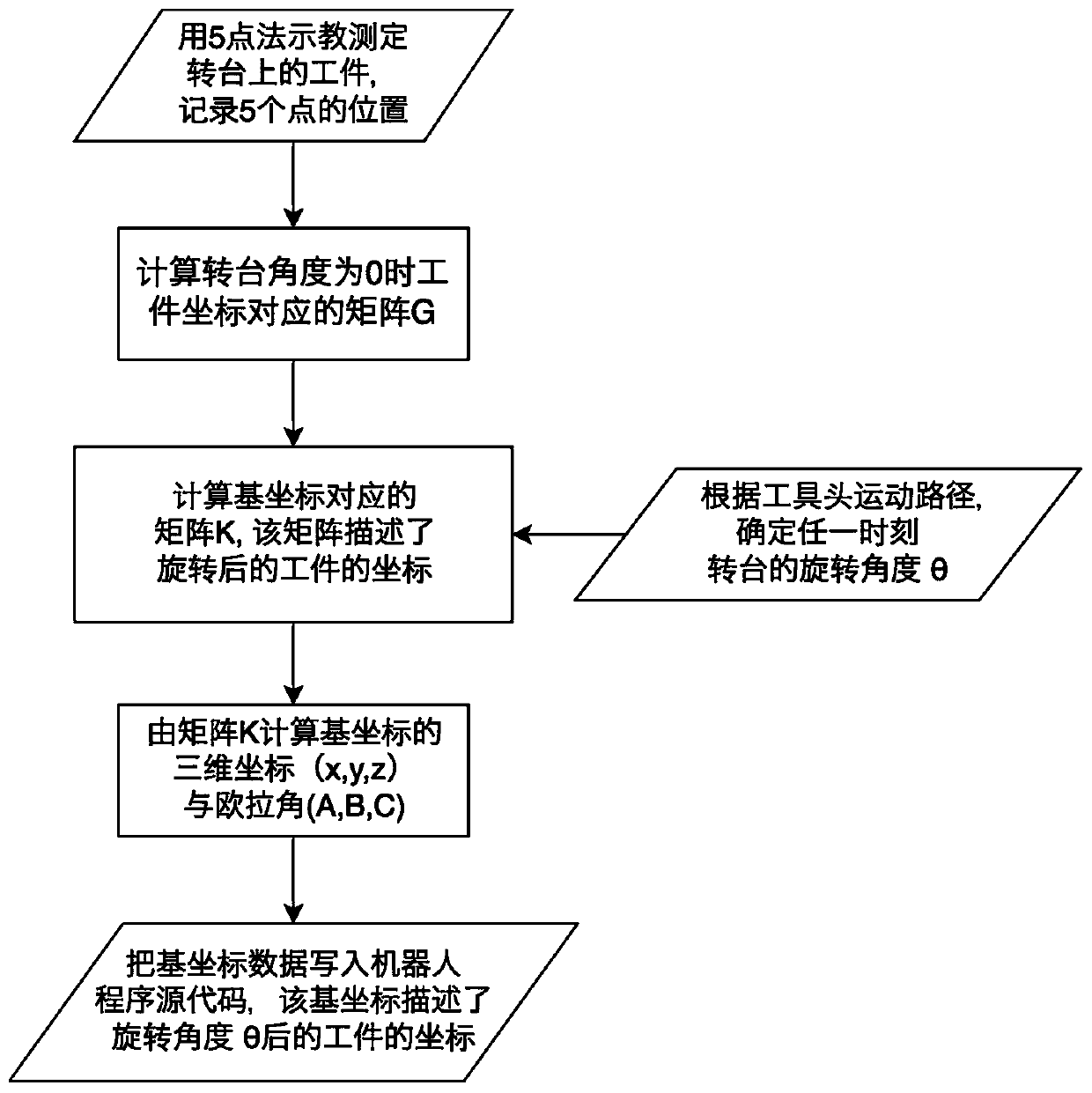

[0065] A method for measuring and using base coordinates of a rotatable workpiece in an industrial robot system according to the present invention comprises the following steps:

[0066] Step 1: Use the robot system, select the corresponding coordinate system in the teaching pendant, select and record the positions of 5 points on the workpiece, and measure the rotatable workpiece through teaching of 5 points; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com