Manual and automatic integrated double guide column type vehicle hanging mechanism for industrial use

A double-guide column type, suspension mechanism technology, applied in the direction of vehicle components, suspensions, elastic suspensions, etc., can solve the problems of inconvenient installation and debugging, large space occupation, and unsmooth steering, and achieve convenient installation, debugging, maintenance, and manufacturing Low cost, easy installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

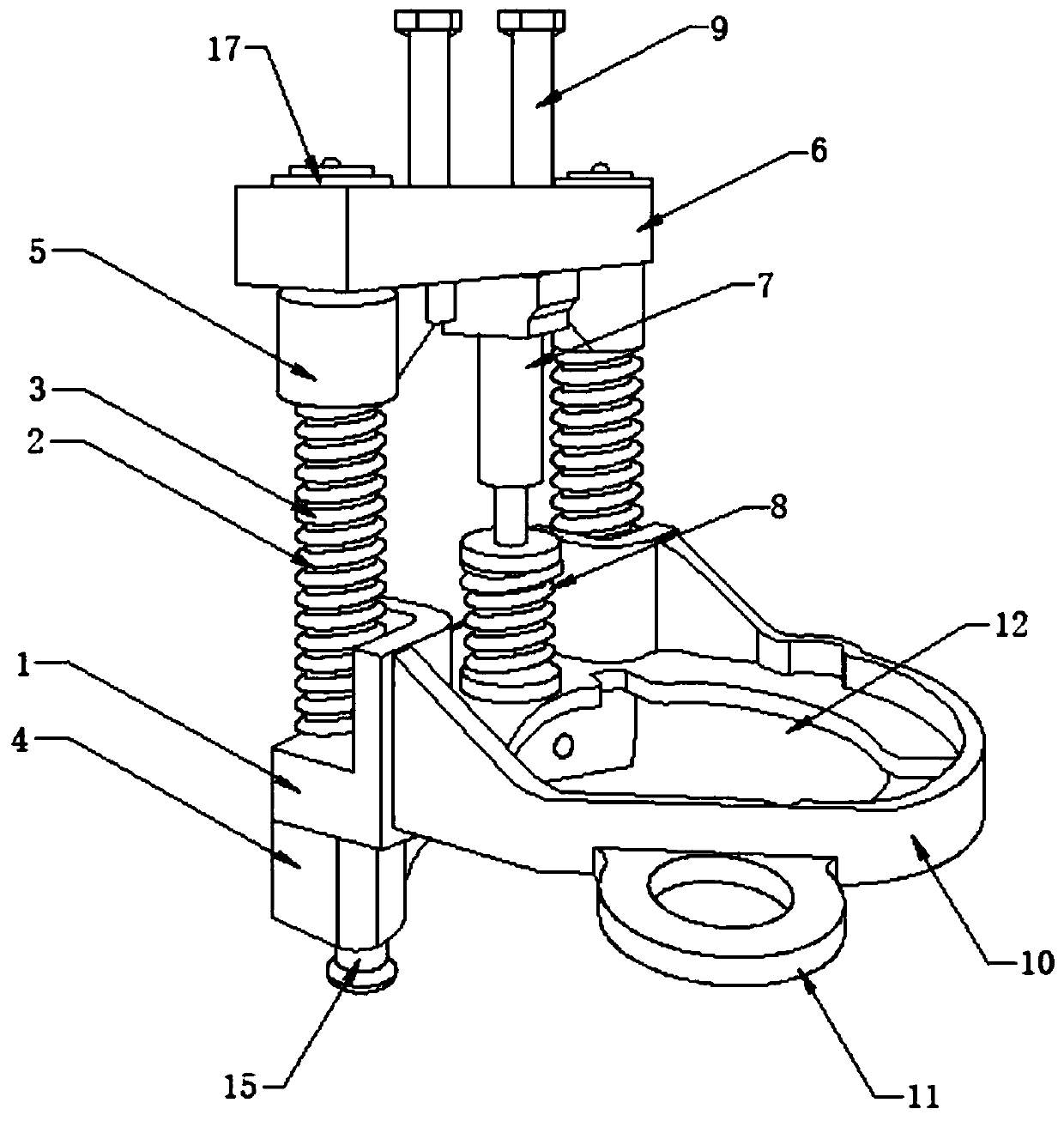

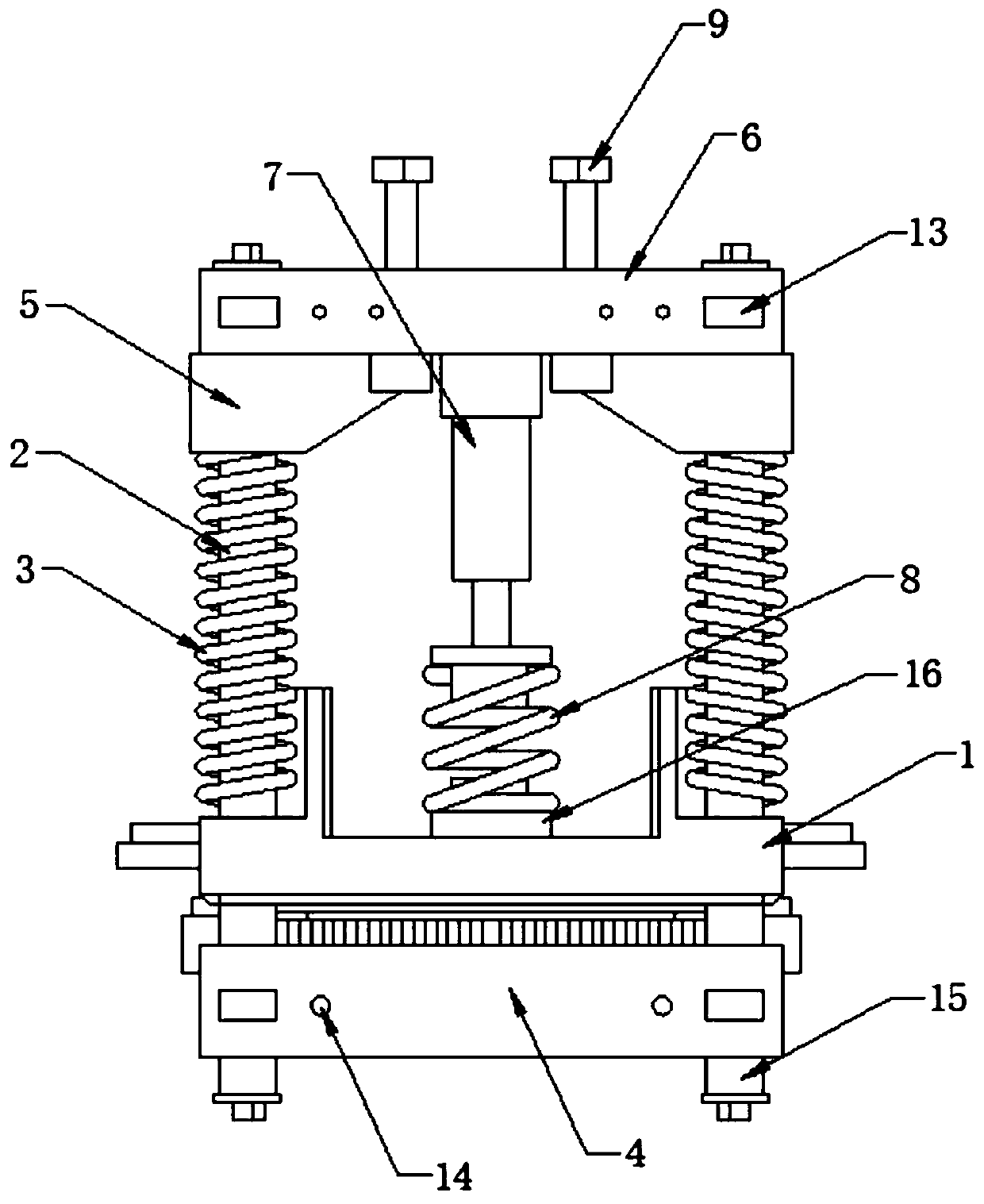

[0020] Such as Figure 1-2 As shown, the present invention provides an industrial manual self-integrated dual-guide column vehicle suspension mechanism, which includes a suspension main body 1, a lower fixing block 4 is arranged at the bottom of the suspension main body 1, and guide rails are installed on both sides of the top of the suspension main body 1. Column 2, a high-strength spring 3 is sleeved on the outer side of the guide rail column 2, a mechanical booster sleeve 5 is connected to the top of the guide rail column 2, and an upper fixed block 6, a lower fixed block 4 and an upper fixed block are installed on the top of the mechanical booster sleeve 5 One side surface of the block 6 is provided with a protruding block 13, the protruding block 13 is a rectangular protruding structure, one side of the protruding block 13 is provided with a mounting hole 14, and the center of the bottom end of the upper fixed block 6 is provided with a hydraulic auxiliary booster. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com