Cleaning and pre-filming method for circulating water system in park

A circulating water system and pre-membrane technology, applied in chemical instruments and methods, natural water treatment, descaling and water softening, etc., can solve problems affecting the normal operation of the circulating water system, production process imbalance, etc., to reduce water eutrophication The risk of pollution, slow down the generation of fouling, the effect of low phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

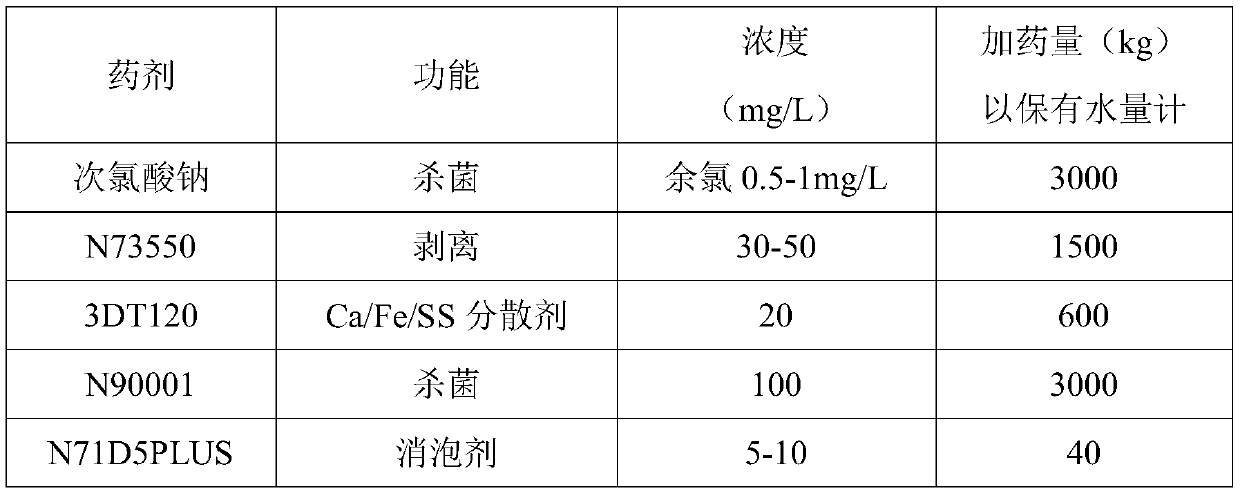

[0034] 1 Preliminary cleaning stage

[0035] 1) Preliminary cleaning steps

[0036] Lower the liquid level of the suction pool (5.0-5.3m of the suction pool) to make the circulation pump run at a low liquid level. Ensure that all heat exchangers are put into operation, and ensure that the flow rate of the heat exchanger is not lower than 1.0 m / s. During the cleaning period, it is forbidden to open the sewage system and close the side filter device.

[0037] Artificial impact dosing of N73550 with a concentration of 30mg / L, and circulation for 1 hour to fully mix the agents.

[0038] Then continuously add sodium hypochlorite to the system to quickly increase the residual chlorine to 0.5-1.0mg / L within 5-8 hours.

[0039] Keep circulating for 24 hours, overflow is strictly prohibited, and the change of turbidity is monitored.

[0040] A lot of foam will appear during the chemical cleaning process, you can add an appropriate amount of non-silicon defoamer N71D5PLUS, the conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com