High-strength and low-temperature-resistant forklift door frame structural steel and preparing method thereof

A forklift mast and low-temperature-resistant technology, which is applied in the field of steel rolling and material metallurgy, can solve the problems of insufficient low-temperature resistance and deterioration of low-temperature resistance of high-strength steel, and achieve wide environmental adaptability, low-temperature impact toughness improvement, and reasonable cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

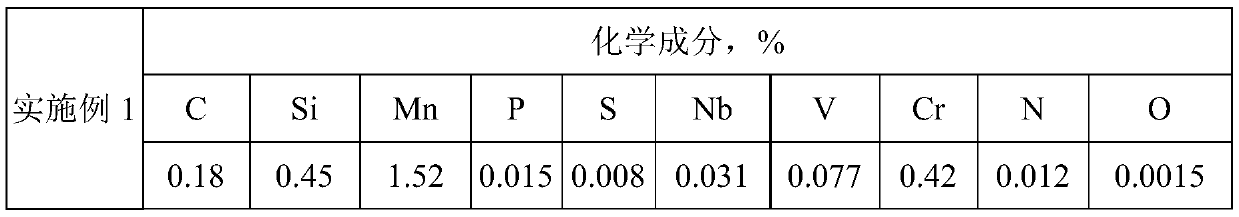

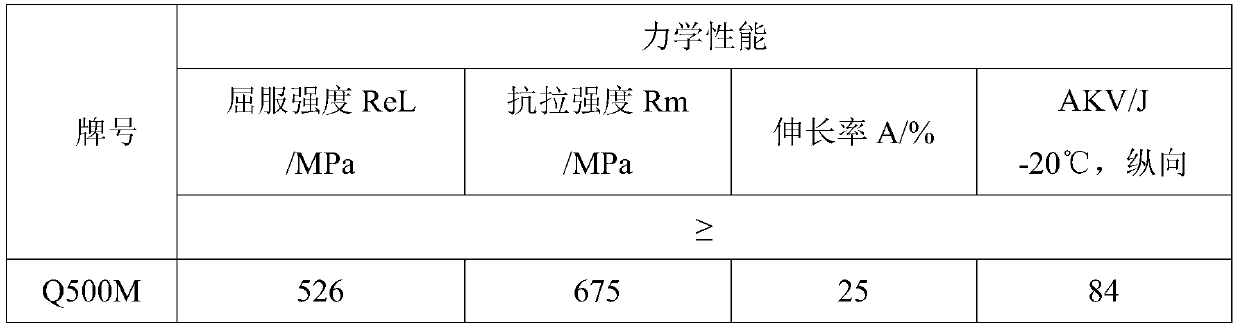

Embodiment 1

[0021] A high-strength and low-temperature-resistant forklift mast section steel, the material composition of which is controlled in the following range by weight percentage:

[0022] C: 0.15% to 0.20%, Si: 0.35% to 0.50%, Mn: 1.40% to 1.60%, P≤0.020%, S≤0.010%, V: 0.07% to 0.09%, Nb: 0.025% to 0.04%, Cr: 0.30%-0.45%, N: 0.011%-0.016%, O≤0.003%, and the rest are iron and unavoidable impurities.

[0023] Based on the above-mentioned preparation method of a high-strength and low-temperature-resistant forklift mast section steel, the preparation method includes the following steps:

[0024] (1) Converter smelting, using ferro-aluminum manganese for deoxidation, ferro-aluminum manganese 1.5 kg / ton of steel, adding vanadium-nitrogen alloy, ferro-niobium, and medium-carbon ferro-chromium for microalloying;

[0025] (2) LF refining, after refining and removing white slag, feed aluminum wire at one time according to the situation, after the temperature and composition of molten steel...

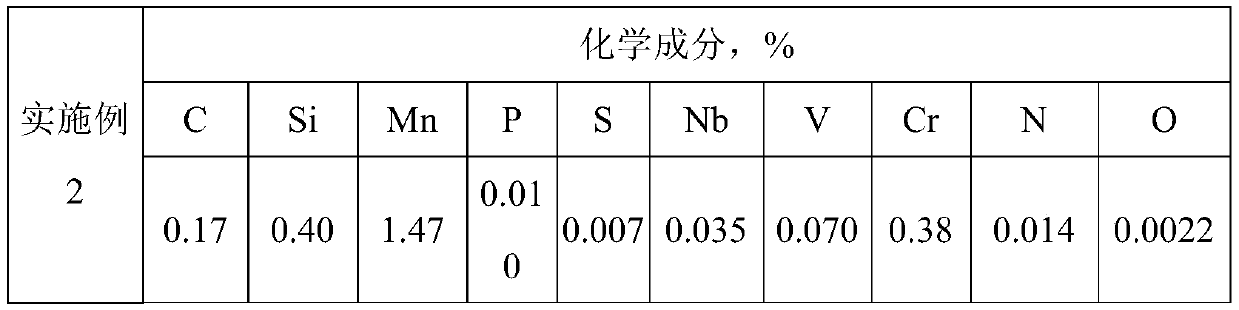

Embodiment 2

[0036] A high-strength and low-temperature-resistant forklift mast section steel, the material composition of which is controlled in the following range by weight percentage:

[0037] C: 0.15% to 0.20%, Si: 0.35% to 0.50%, Mn: 1.40% to 1.60%, P≤0.020%, S≤0.010%, V: 0.07% to 0.09%, Nb: 0.025% to 0.04%, Cr: 0.30%-0.45%, N: 0.011%-0.016%, O≤0.003%, and the rest are iron and unavoidable impurities.

[0038] Based on the above-mentioned preparation method of a high-strength and low-temperature-resistant forklift mast section steel, the preparation method includes the following steps:

[0039] (1) Converter smelting, using Al-Mn-Fe for deoxidation, Al-Mn-Fe 2 kg / ton of steel. Add vanadium-nitrogen alloy, ferro-niobium, and medium-carbon ferrochrome for microalloying;

[0040] (2) LF refining, after refining and removing white slag, feed aluminum wire at one time according to the situation, after the temperature and composition of molten steel meet the pouring requirements, feed ca...

Embodiment 3

[0051] A high-strength and low-temperature-resistant forklift mast section steel, the material composition of which is controlled in the following range by weight percentage:

[0052] C: 0.15% to 0.20%, Si: 0.35% to 0.50%, Mn: 1.40% to 1.60%, P≤0.020%, S≤0.010%, V: 0.07% to 0.09%, Nb: 0.025% to 0.04%, Cr: 0.30%-0.45%, N: 0.011%-0.016%, O≤0.003%, and the rest are iron and unavoidable impurities.

[0053] Based on the above-mentioned preparation method of a high-strength and low-temperature-resistant forklift mast section steel, the preparation method includes the following steps:

[0054] (1) Converter smelting, using Al-Mn-Fe for deoxidation, Al-Mn-Fe 2 kg / ton steel, adding vanadium-nitrogen alloy, ferro-niobium, and medium-carbon ferro-chrome for micro-alloying;

[0055] (2) LF refining, after refining and removing white slag, feed aluminum wire at one time according to the situation, after the temperature and composition of molten steel meet the pouring requirements, feed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com