Inspection well installation structure and construction method

A technology of installation structure and construction method, applied in infrastructure engineering, underwater structures, excavation, etc., can solve the problems affecting the safety of vehicles and pedestrians, sinking site, loose roadbed, etc., to reduce settlement, increase stability, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

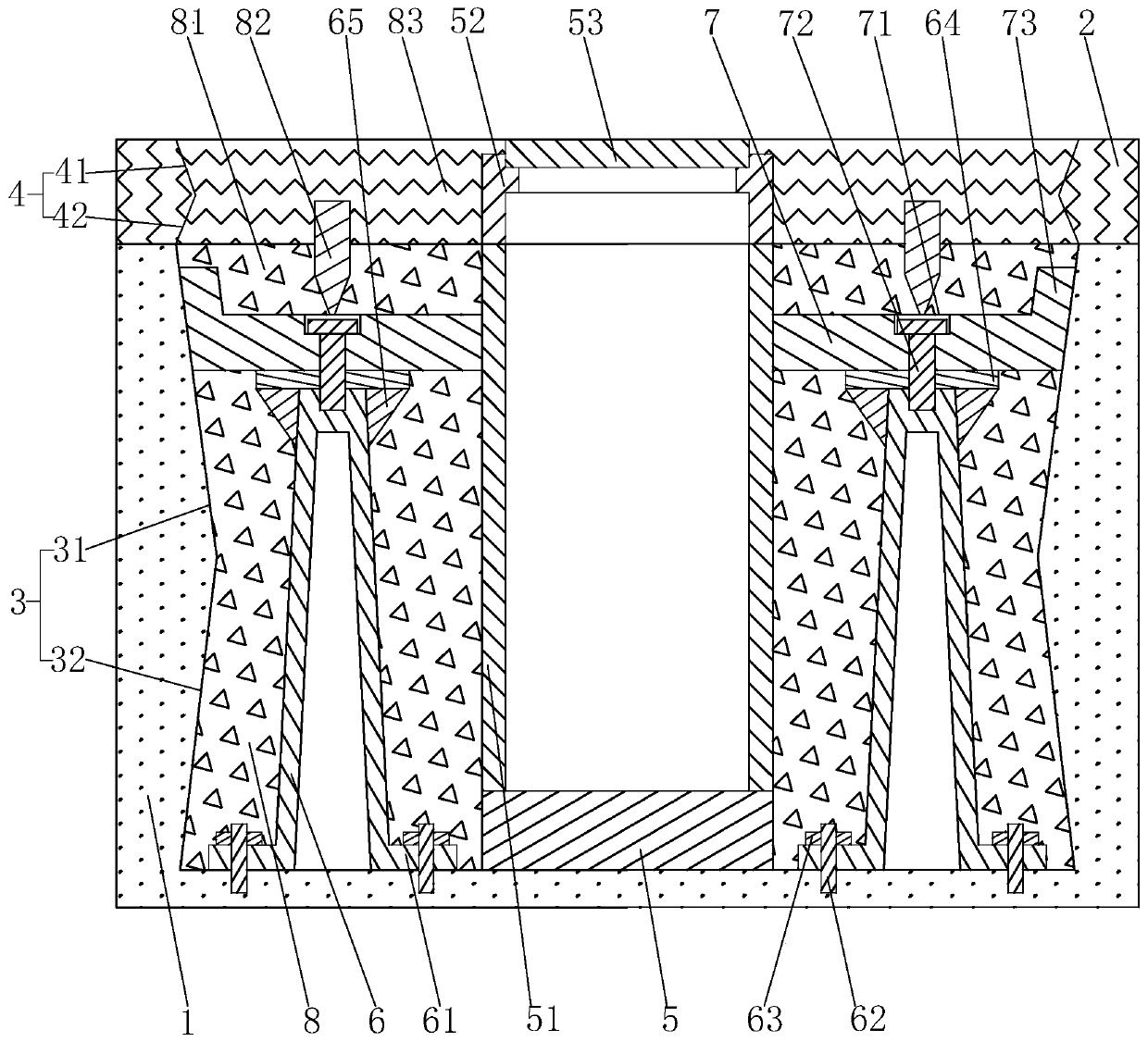

[0042] An installation structure for an inspection well, such as figure 1As shown, the installation structure is used to install the inspection well 51 on the road base 1 , and the top surface of the road base 1 is laid with an asphalt pavement 2 . The installation structure includes a first foundation pit 3 and a second foundation pit 4. The first foundation pit 3 is set on the subgrade 1. The first foundation pit 3 includes a first upper foundation pit 31, a first lower foundation pit 32, and a first lower foundation pit 3. The inner side wall of the foundation pit 32 is set on a conical surface, and the angle between the inner side wall of the first lower foundation pit 32 and the vertical plane is 10°, the first upper foundation pit 31 is located above the first lower foundation pit 32, and the first upper foundation pit 32 The inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com