Suspended prefabricated shear wall semi-buried inner wall connecting structure and method

A technology for connecting structures and prefabricated shear forces, applied to structural elements, walls, building components, etc., can solve the problems of influence and difficulty in controlling the appropriate amount of grouting construction, and achieve the effect of simplifying the construction process, controlling the amount of grouting construction, and reducing the project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

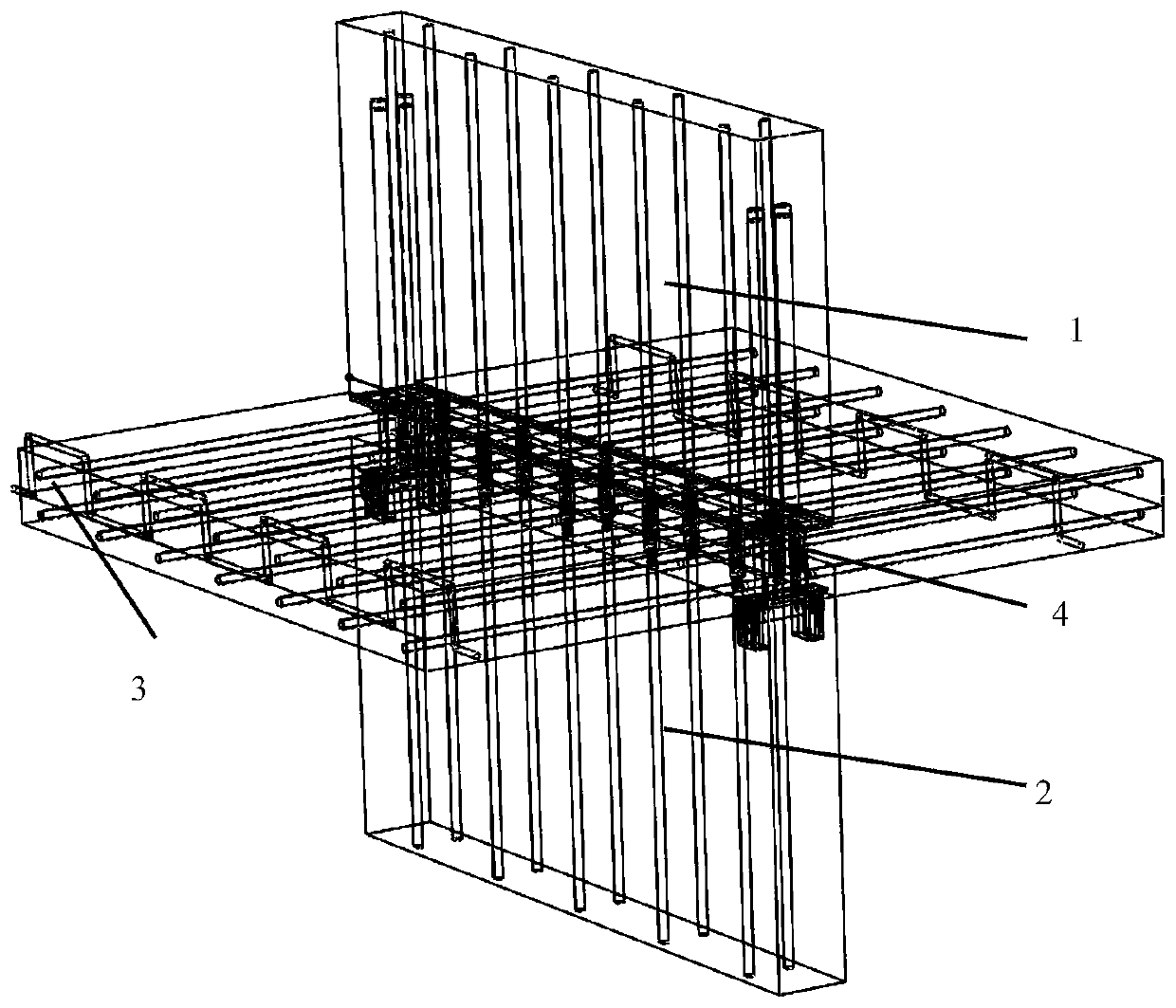

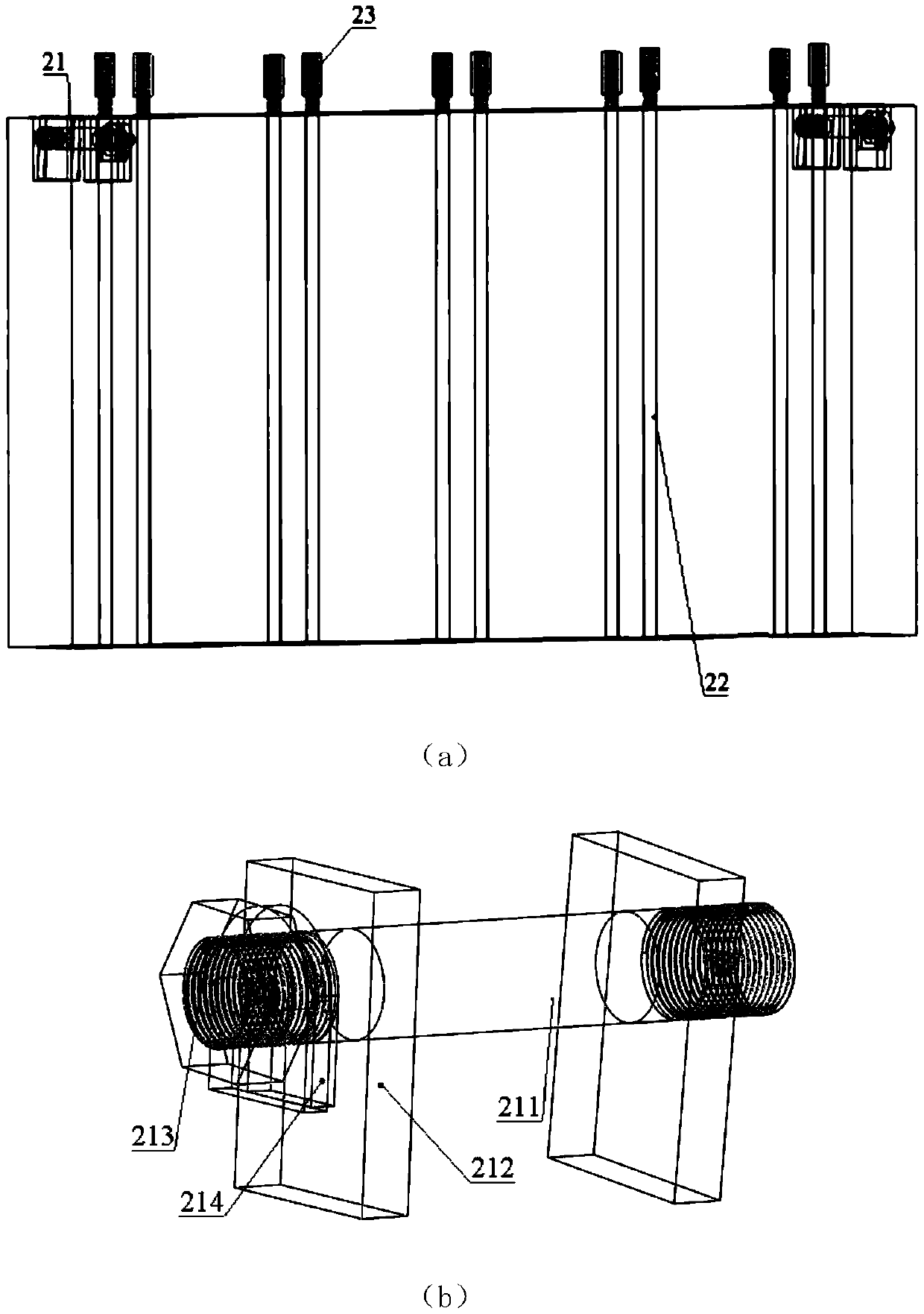

[0049] This embodiment provides a suspended prefabricated shear wall semi-buried interior wall connection structure, which includes an upper suspended wall 1 , a lower wall 2 , a poured surface layer 3 and a prefabricated laminated floor 4 . The lower wall 2 here is also the lower bracket wall, in which the upper suspended wall 1, the lower bracket wall, the prefabricated bottom plate 4 and their accessories are manufactured and maintained in the prefabrication factory, and the whole pouring surface layer 3 is completed in the floor slab Concrete is poured on site after binding the upper steel bars to complete the wall connection.

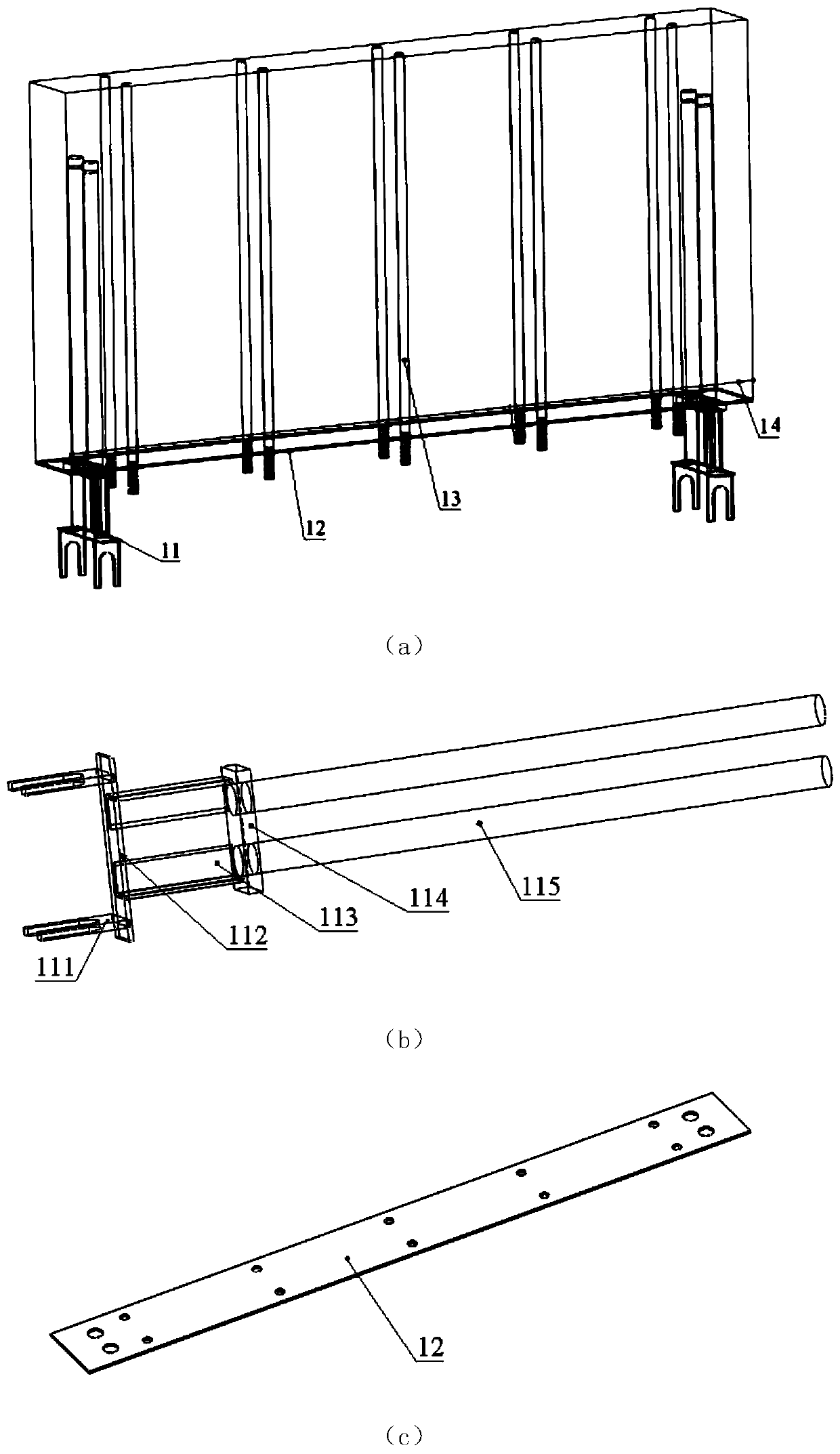

[0050] The upper suspended wall body 1 includes a lifting frame 11 , a steel bar positioning plate 12 , a prefabricated upper end threaded steel bar 13 and a control line 14 for the entire pouring surface layer.

[0051] The lifting frame 11 is composed of an ear plate 111, a cantilever plate 112, a supporting angle steel 113, an end anchor plate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com