Flange for plastic processing exhaust gas transmission

A technology using flanges and exhaust gas, which is applied in flange connections, pipeline heating/cooling, pipes/pipe joints/fittings, etc., can solve the problems of pipeline blockage, waste liquid cannot be removed, and high energy consumption, so as to reduce energy consumption, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

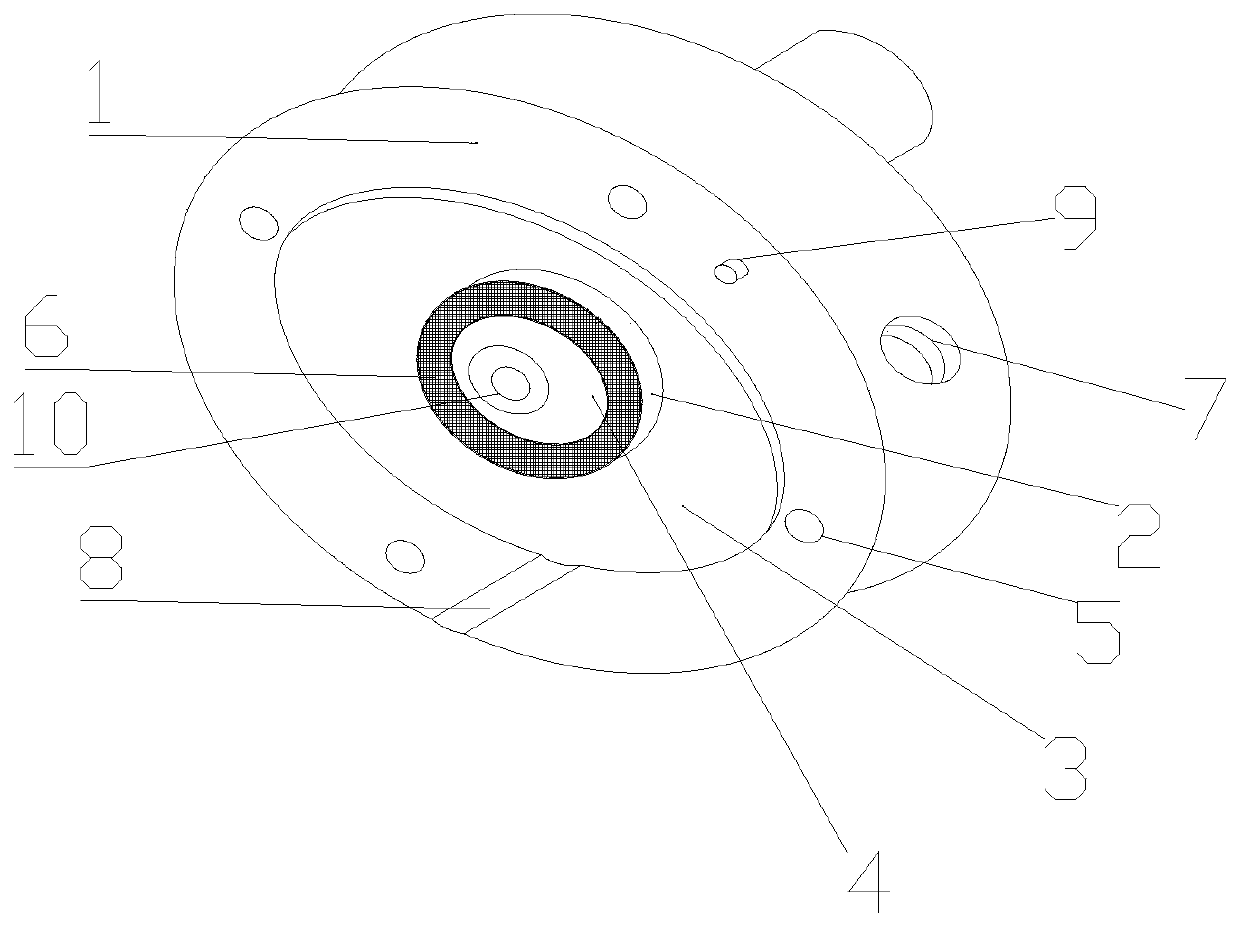

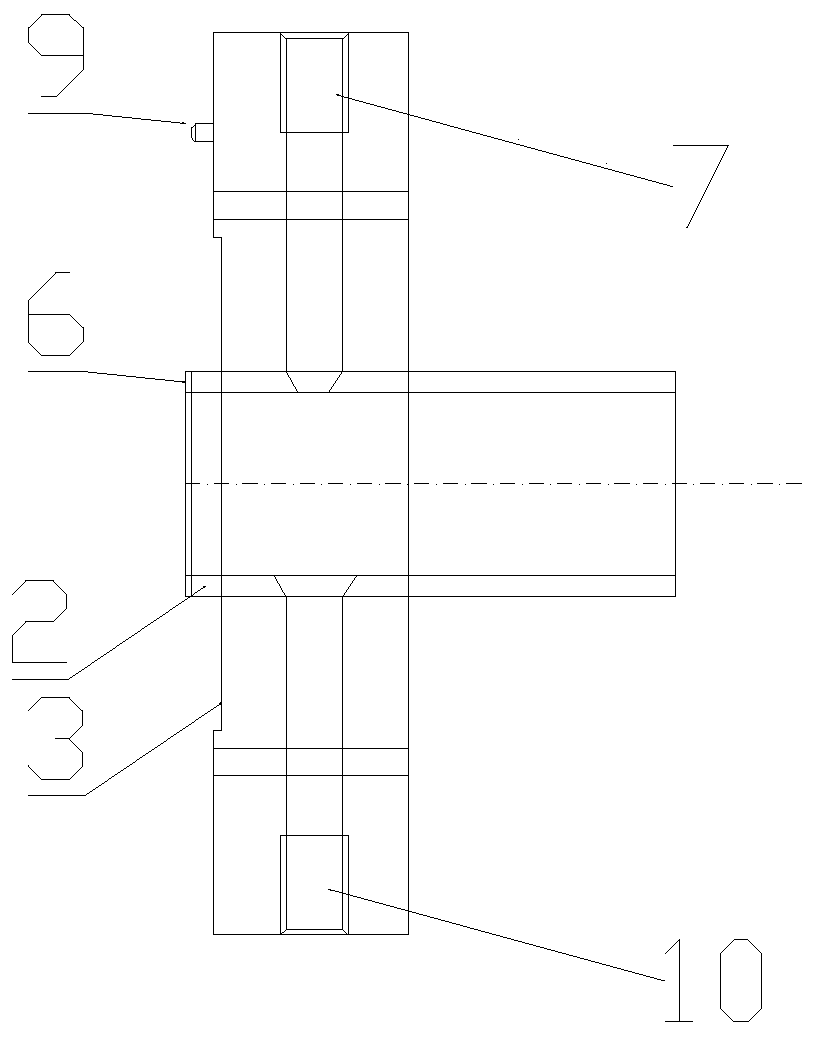

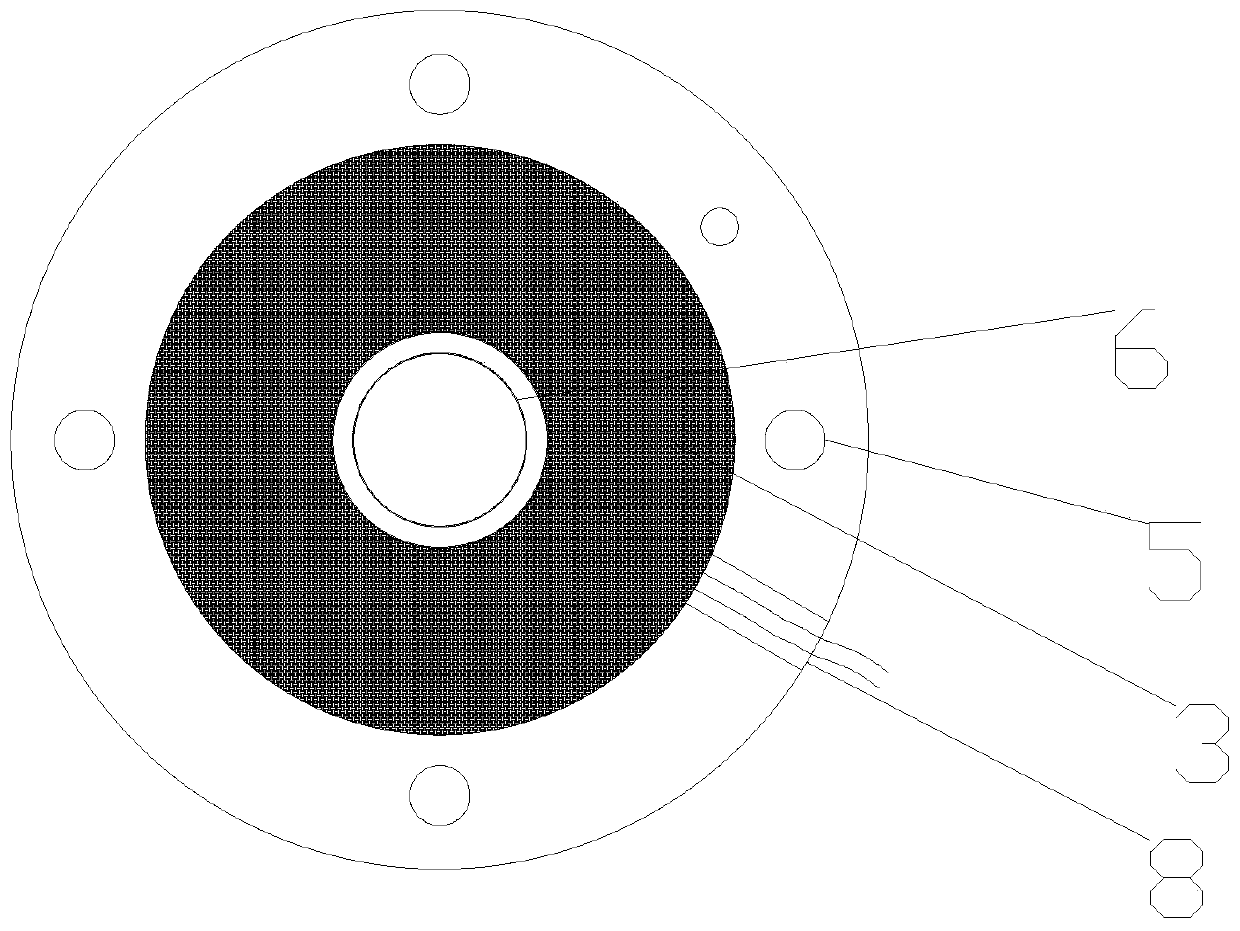

[0025] refer to Figure 1-Figure 3 As shown, a flange used for conveying waste gas from plastic processing is composed of a flange shell 1, a boss 2, a heating groove 3, a through hole 4, a bolt hole 5, a ring groove 6, a temperature measuring hole 7, and a wire groove 8. The positioning pin 9 and the waste discharge hole 10 are formed. The through hole 4 is located in the center of the flange shell 1; the boss 2, the heating groove 3, the wire groove 8, and the positioning pin 9 are located on the flange assembly surface; the height of the boss 2 is greater than The height of the positioning pin 9, the end surface of the boss 2 is provided with a circular groove 6 for placing the sealing ring; the bolt holes 5 are symmetrically and evenly distributed on the flange shell 1 for the assembly of the flange; the heating groove 3 is a circular ring shape, located between the through hole 4 and the bolt hole 5; the temperature measuring hole 7 and the waste discharge hole 10 are set...

Embodiment 2

[0035] refer to Figure 1-Figure 3 As shown, a flange used for conveying waste gas from plastic processing is composed of a flange shell 1, a boss 2, a heating groove 3, a through hole 4, a bolt hole 5, a ring groove 6, a temperature measuring hole 7, and a wire groove 8. The positioning pin 9 and the waste discharge hole 10 are formed. The through hole 4 is located in the center of the flange shell 1; the boss 2, the heating groove 3, the wire groove 8, and the positioning pin 9 are located on the flange assembly surface; the height of the boss 2 is greater than The height of the positioning pin 9, the end surface of the boss 2 is provided with a circular groove 6 for placing the sealing ring; the bolt holes 5 are symmetrically and evenly distributed on the flange shell 1 for the assembly of the flange; the heating groove 3 is a circular ring shape, located between the through hole 4 and the bolt hole 5; the temperature measuring hole 7 and the waste discharge hole 10 are set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com