Canyon high-stress area hard rock large underground cavern axis arrangement quantitative design method

A technology for high-stress areas and underground caverns, applied in underground chambers, computing, mining equipment, etc., can solve problems such as the inability to reasonably reflect the spatial distribution characteristics of the in-situ stress field, and achieve the goal of reducing construction risks, easy to implement, and clear indicators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

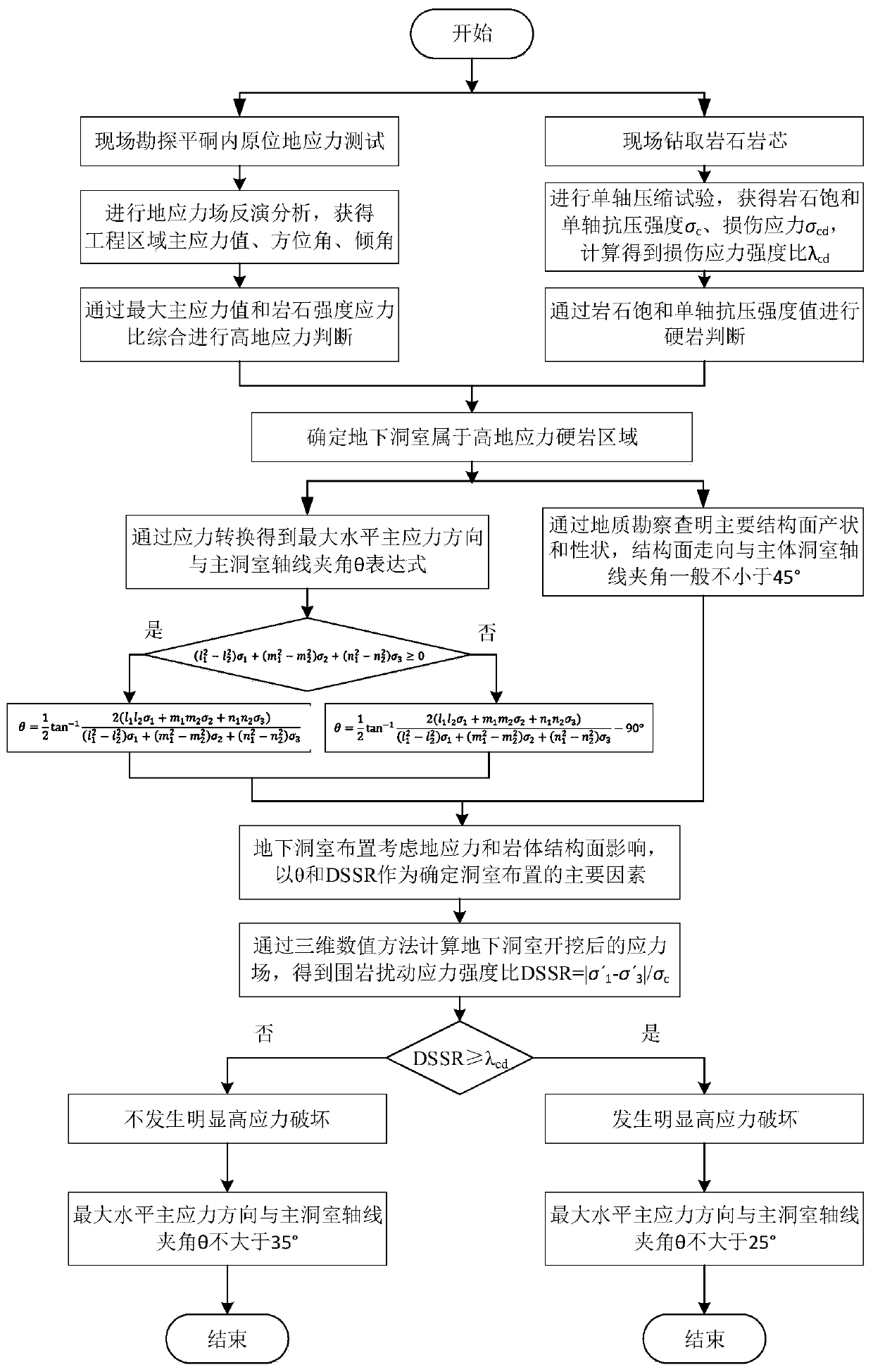

[0029] Such as figure 1 As shown, the implementation steps of a quantitative design method for axis layout of large-scale underground caverns in hard rock in high-stress areas of canyons in the present invention are as follows:

[0030] Step 1: In the preliminarily planned underground cavern layout area, select typical parts through on-site exploration ark for in-situ stress testing. Relief method to obtain the first principal stress value σ of the measuring point 10 and azimuth β 10 and inclination α 10 , the value of the second principal stress σ 20 Spatial distribution and azimuth β 20 and inclination α 20 , the value of the third principal stress σ 30 and azimuth β 30 and inclination α 30 spatial distribution. The number of ground stress measuring po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com