A reed structure for preventing axial movement of motors, motors, and household appliances

A technology of axial movement and reed, which is applied in household appliances, motors, and the field of reed structures to prevent axial movement of motors. It can solve the problems of axial force on gears, reduce axial force and avoid collisions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

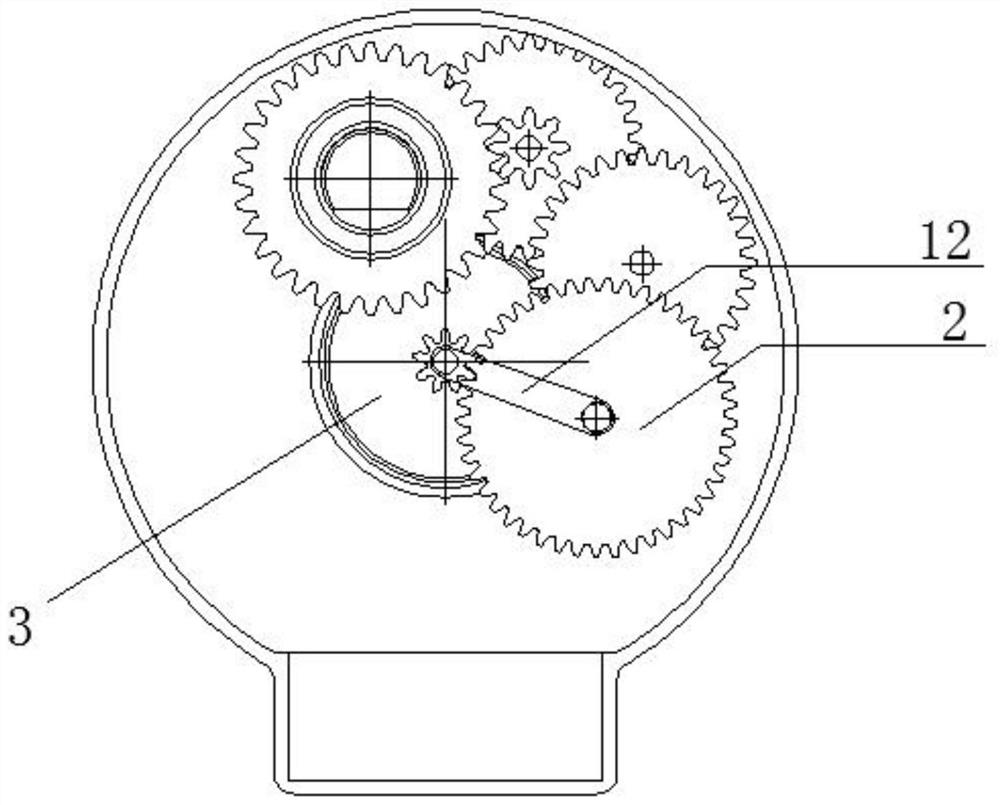

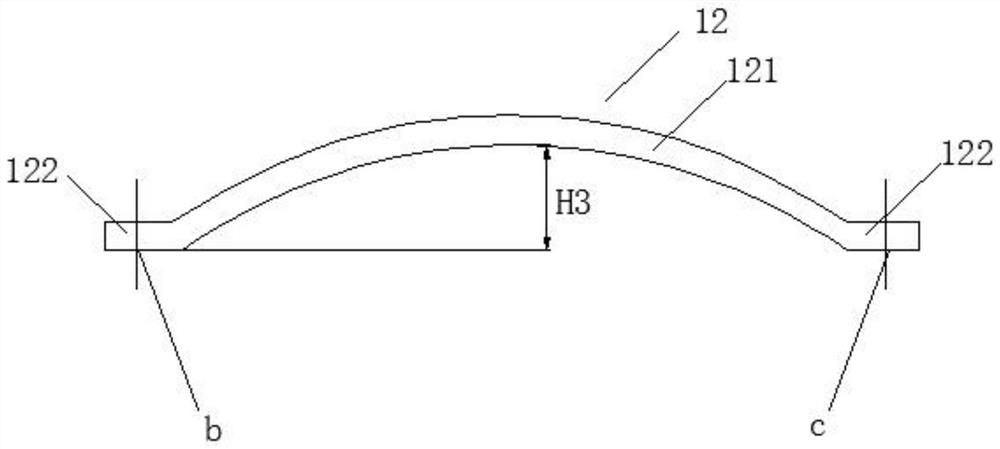

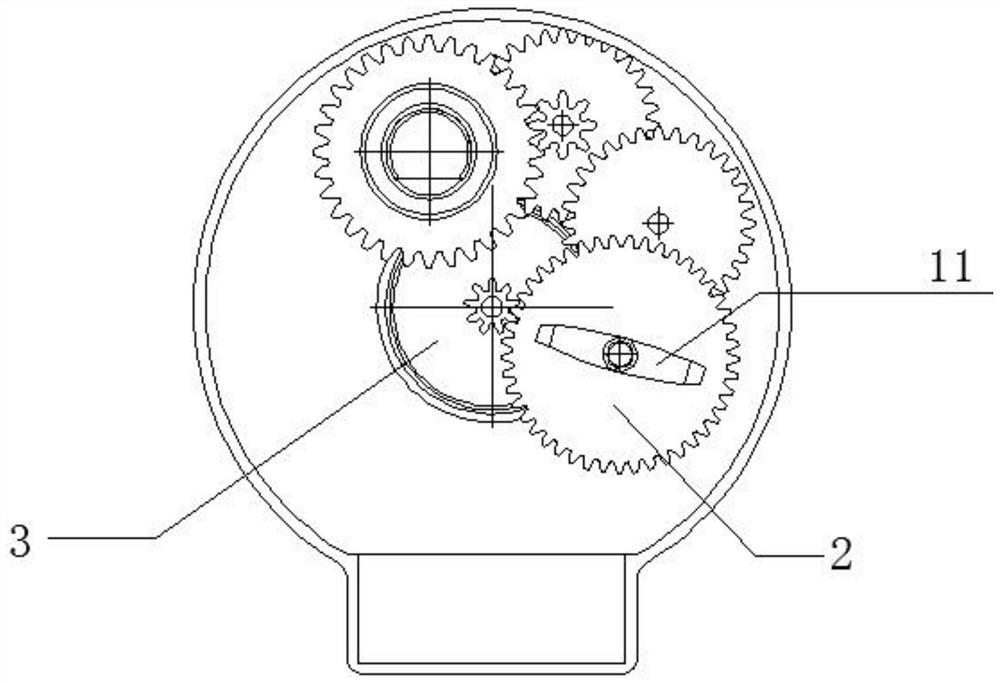

[0029] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0030] Aiming at the problems existing in the prior art, the present invention provides a reed structure for preventing axial movement of the motor. figure 1 to attach Figure 4 The present invention is described in detail.

[0031] The permanent magnet synchronous motor is a synchronous motor that is excited by permanent magnets to generate a synchronous rotating magnetic field. The induced magnetic field generated by the stator winding interacts with the permanent magnet of the rotor to convert it into kinetic energy. The synchronous motor acts as both a generator and a motor. In the existing technology, during the rotation of the permanent magnet synchronous motor, due to the processing and matching errors of the parts, the gears are subjected to axial for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com