Rotating power conversion assembly and manual profiling type kelp knotting machine

A kelp knotter and rotary power technology, applied in food science and other directions, to achieve the effect of reducing damage speed, reducing eccentricity problem and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

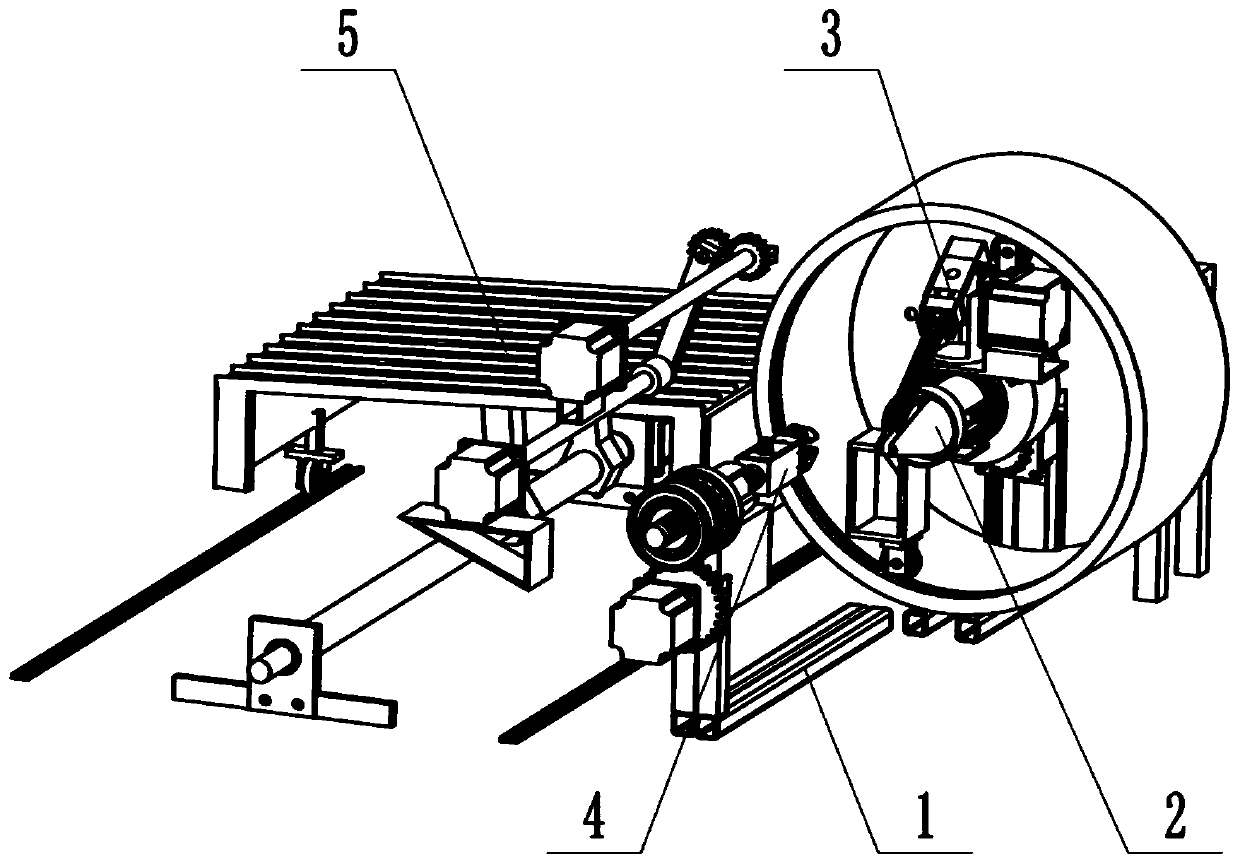

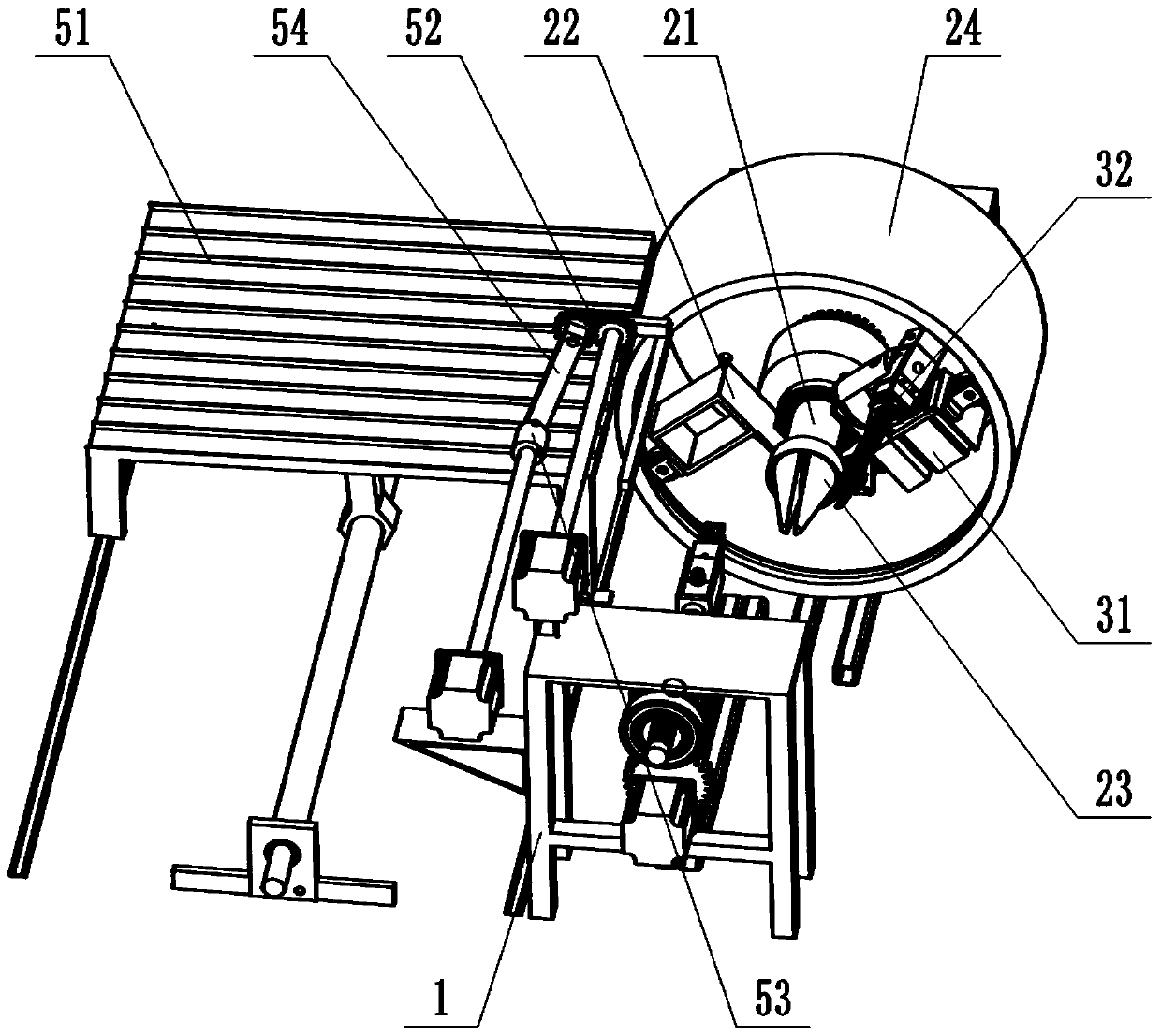

[0030] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

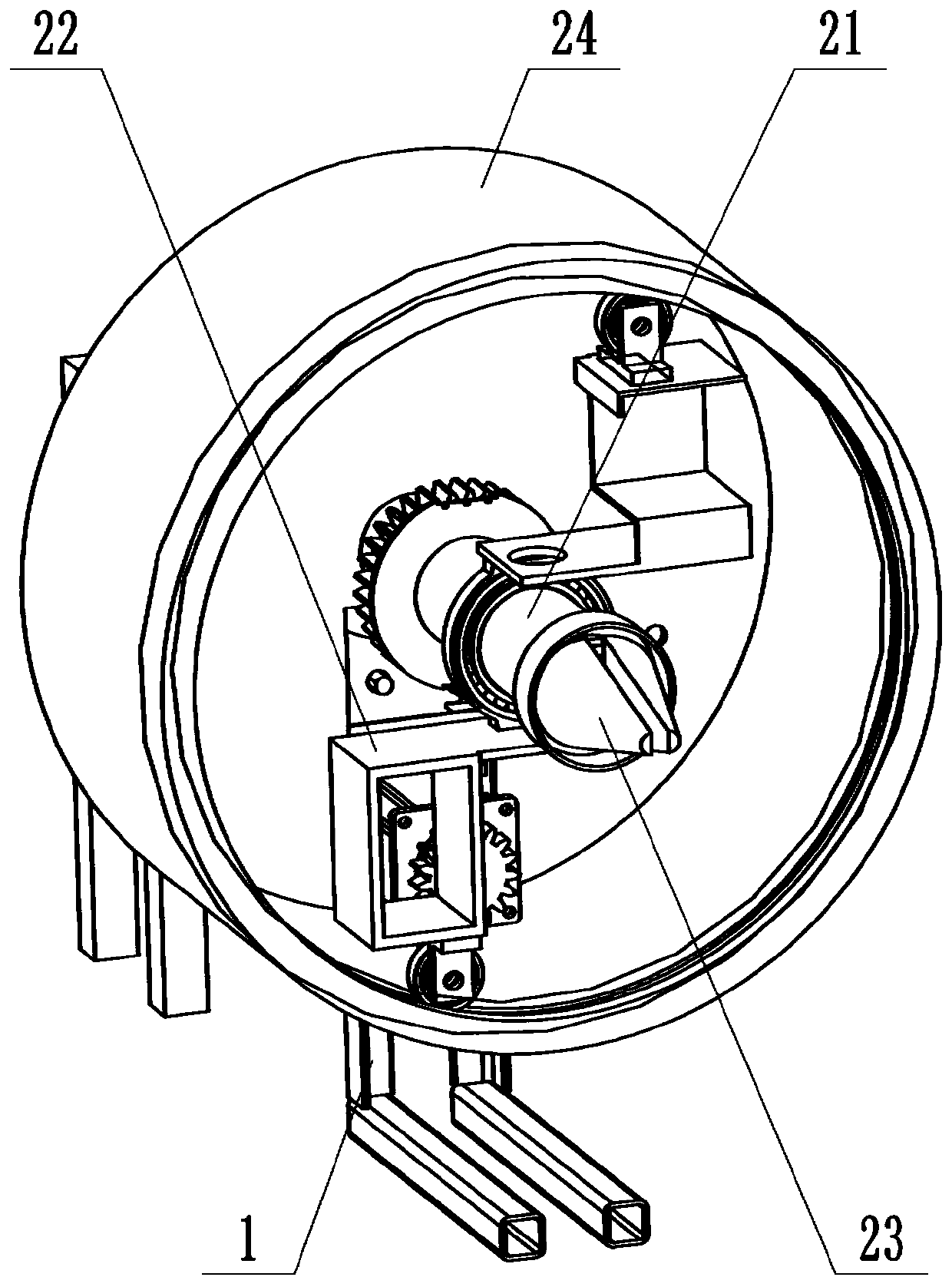

[0031] A rotary power conversion assembly such as figure 1 As shown, it includes frame 1 , slip ring 21 , turret 22 , tapered clamp 23 and sleeve 24 .

[0032] Slip ring 21 is arranged on the frame 1, and the middle part of turret 22 is rotated and arranged on the slip ring 21, and turret 22 can pass such as image 3 The gear device shown is used to provide power, and the deep groove ball bearing is used to rotate on the slip ring 21. The deep groove ball bearing is made of high-purity carbon alloy steel, and its surface is sealed with a rubber cover to prevent dust and oil. The tapered clip 23 is set on the slip ring 21 through a reciprocating assembly, that is, the tapered clip 23 can reciprocate on the slip ring 21. The reciprocating assembly here can be a roller screw or cylinder controlled by a servo motor, the same below . The sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com