High-reflection object surface defect detection device

A technology for object surface and defect detection, which is applied in the field of visual inspection, can solve the problems of not considering the light source, low work efficiency, and limitations of applicable objects, etc., and achieve the effect of wide application range, high industrial value, and high-speed continuous detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

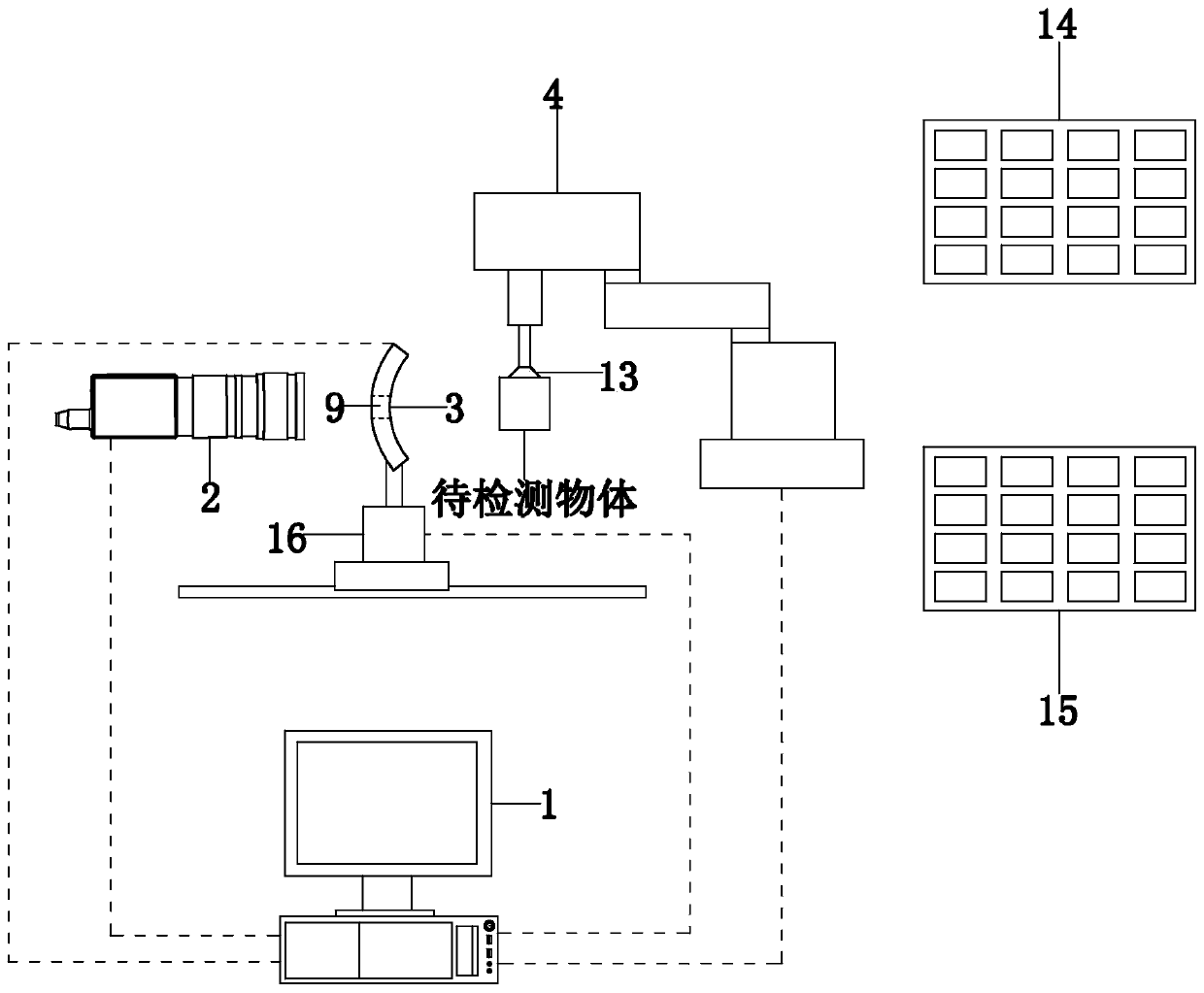

[0027] combine Figure 1 to Figure 5 , the present embodiment is a device for detecting surface defects of highly reflective objects, including a computer 1, an industrial camera 2, a light generator 3, and a loading and unloading mechanism. The loading and unloading mechanism includes a multi-axis manipulator 4, wherein;

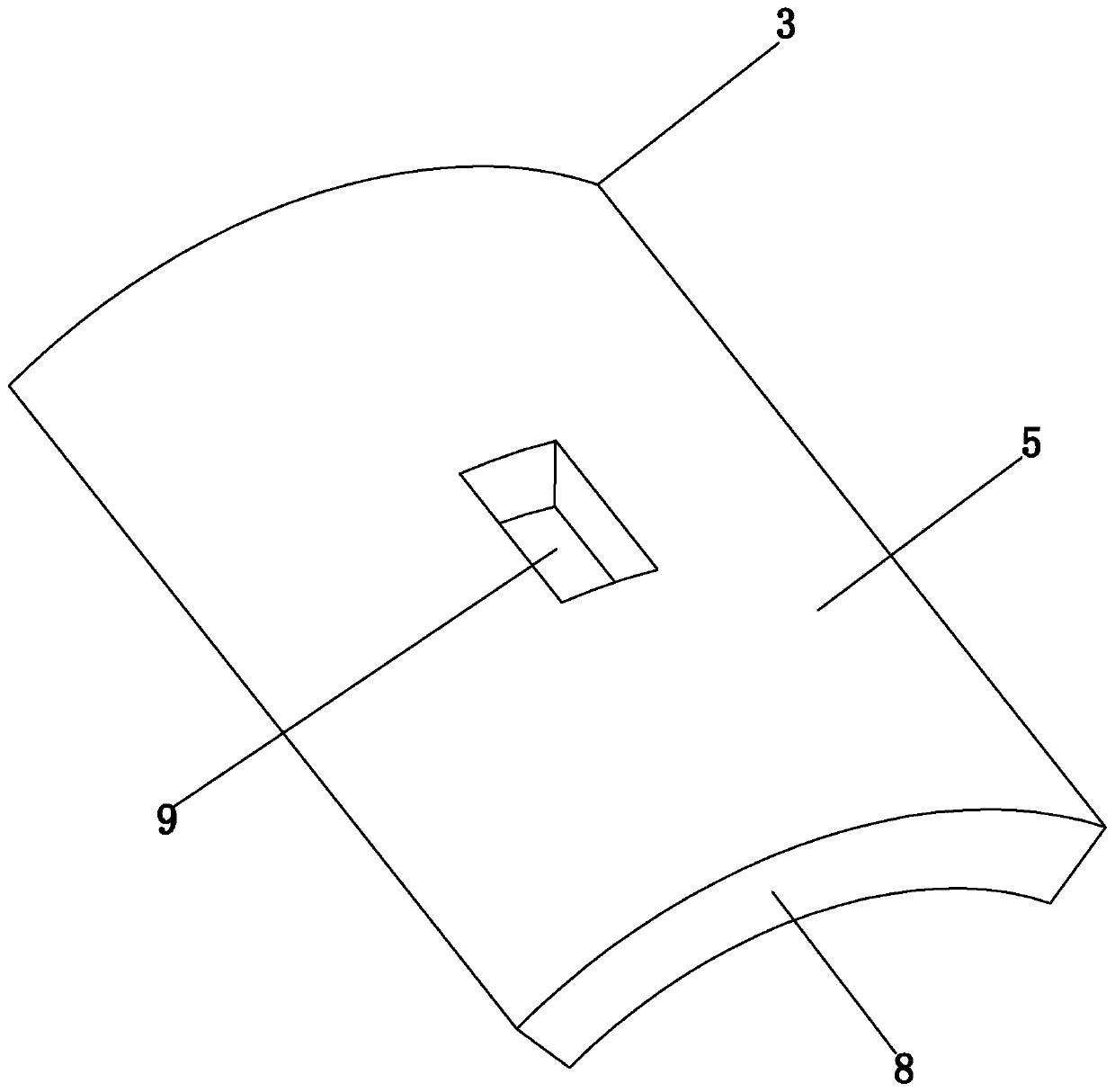

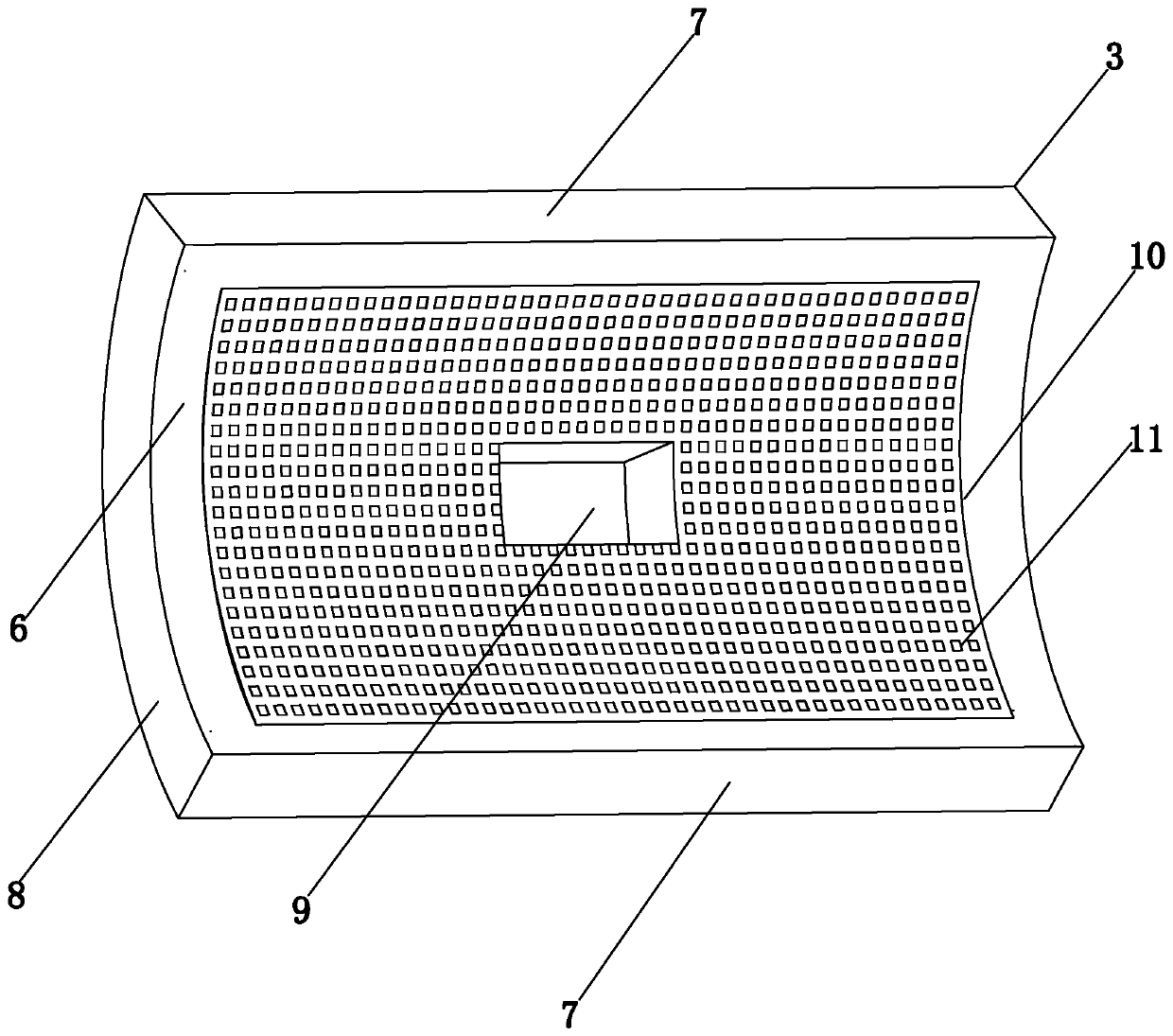

[0028] The light generator 3 is surrounded by an outer arc plate 5, an inner arc plate 6, a pair of side plates 7 and a pair of end plates 8. There is a light inlet hole 9 running through the middle of the arc plate 6, the outer arc plate 5, side plate 7, end plate 8 and the walls of the light inlet hole 9 are all made of opaque material, and the inner arc plate 6 is made of a light-transmitting material, and its inner wall is rough , the outer wall is smooth, the outer wall of the inner arc plate 6 is covered with a light-transmitting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com