Base for masking tape for coating and masking tape for coating

A tape and paint technology, which is applied in the direction of surface coating liquid devices, coatings, adhesives, etc., can solve the problems of paint falling off, poor followability of curved surfaces, and adhesive layer peeling residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0057] Embodiment 1-8, comparative example 1-3

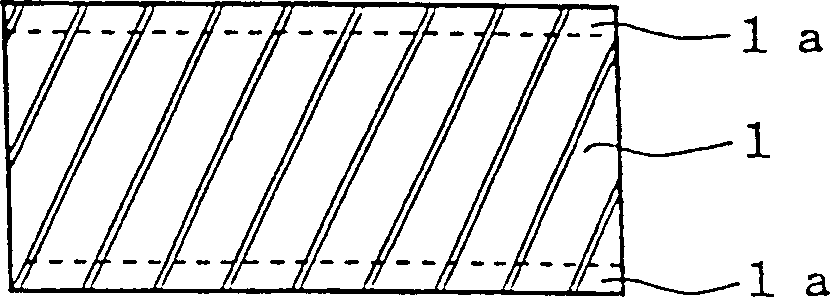

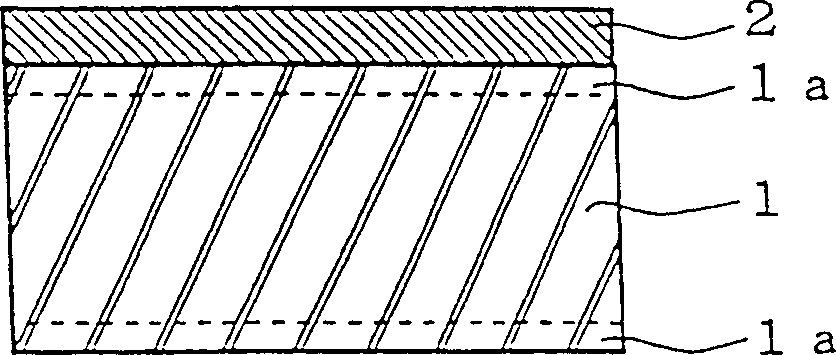

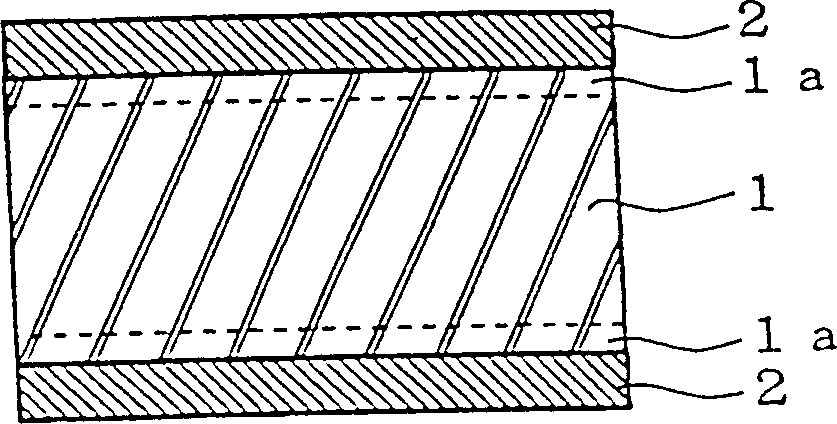

[0058] On the surface of a polyolefin resin film having the physical properties shown in Table 1 (PP-PE block copolymer, PP-PE random copolymer, and PE, all manufactured by Toyobo Co., Ltd. were used as the resin), according to Table 2 and the following, corona modification treatment was applied, and F1-F6 paint protection tape substrates provided with modified resin layer (thickness refer to Table 1) and adhesive layer (thickness refer to Table 1) were produced.

[0059] (corona modification treatment conditions)

[0060] Current 1.05A

[0061] Voltage 4.7KV

[0062] Processing speed 180m / min

[0063] (Film formation of modified resin layer)

[0064] On one side or both sides of the corona-modified polyolefin resin film, apply a composition for forming a modified resin layer (Panacia SP709 (white, containing polyisocyanate), manufactured by Dainippon Inki Co., Ltd.) 4-7 μm (dry thick), forming a modified resin layer.

[0...

Embodiment 9

[0135] Acrylic resin adhesive, with n-butyl acrylate as the main component, as a functional group, in 100 parts by weight of a solution (resin component 30%) of a polymer containing carboxyl and epoxy groups, a butyl etherified melamine resin ( A resin component (50%) 1.8 parts by weight and dinonylnaphthalenesulfonic acid (55% solution of isobutanol) 0.2 parts by weight were used to prepare an acrylic resin adhesive composition. This solution was coated on the corona-treated surface of the base material F2 for paint protection tapes shown in Table 1, and dried to form an adhesive layer, whereby a paint protection tape was obtained.

Embodiment 10

[0137] In 100 parts by weight of the adhesive composition used in Example 9, 1.0 part by weight of chlorinated PP (S206 (resin component 50%) manufactured by Nippon Paper Co., Ltd.) was blended to prepare an acrylic resin-based adhesive composition. Outside, other is the same as embodiment 9, makes paint protective tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com