Hub drive device for vehicle and hub drive vehicle

A technology of wheel hub drive and braking device, applied in the field of vehicles, can solve the problems of difficult assembly, insufficient stability, large layout space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

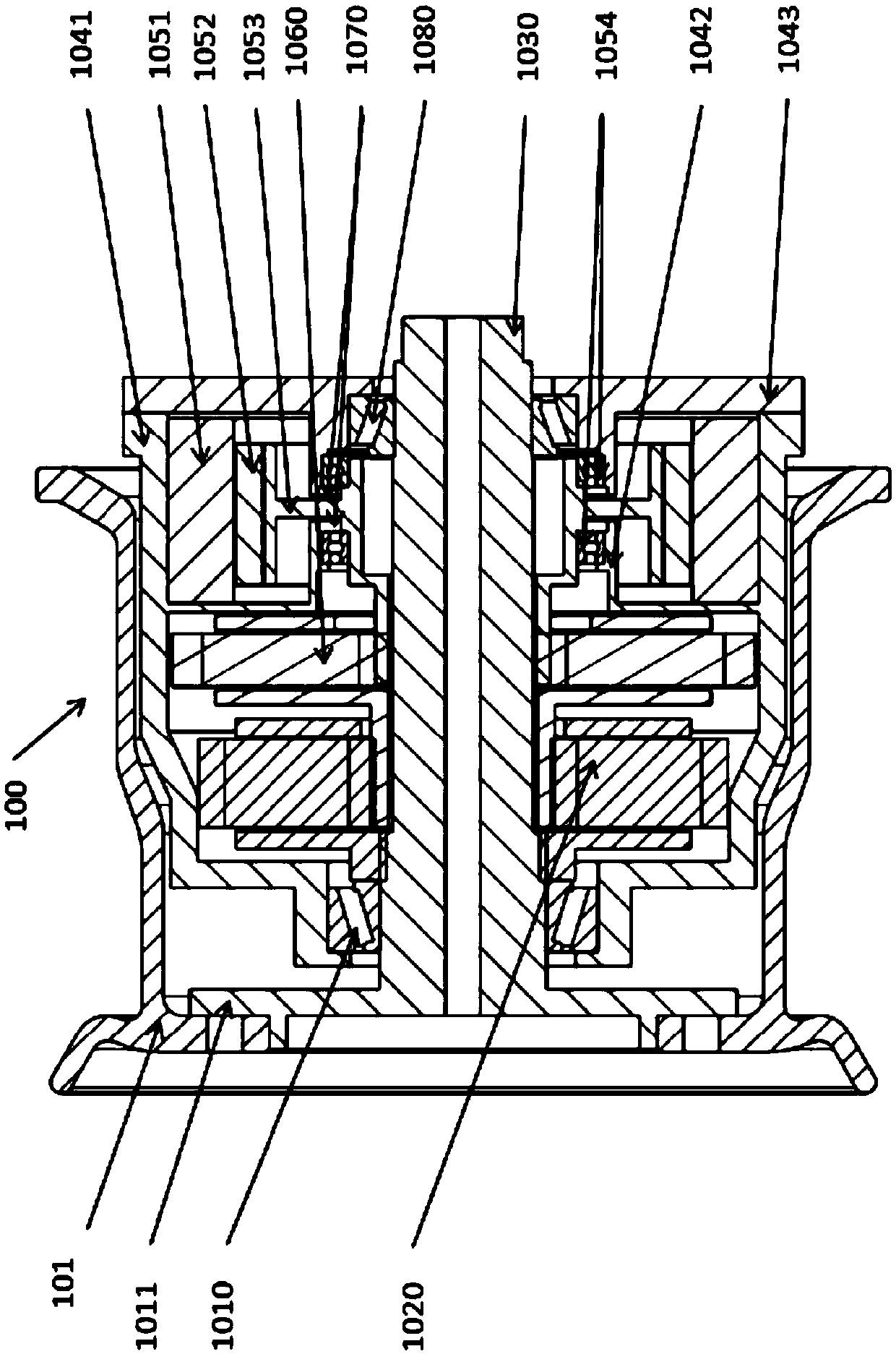

[0014] figure 1 It is a sectional view of the hub drive device 100 of the present invention. Such as figure 1 As shown, the hub driving device 100 includes a motor composed of a stator 1051 and a rotor 1052 , wherein the stator 1051 is fixed on the housing 1041 , and the rotor 1052 is fixed on the rotor bracket 1053 . The rotor bracket 1053 is respectively supported on the support plate 1042 and the housing cover 1043 through the rotor bearing 1054 . The housing cover 1043 is fixed on the housing 1041 . When the motor is running, the rotor 1052 together with the rotor bracket 1053 rotates relative to the support plate 1042 / housing cover 1043 .

[0015] The hub driving device 100 includes two reduction stages, namely, the first reduction stage—the first stage planetary gear set 1060 and the second reduction stage—the second stage planetary gear set 1020 . The sun gear of the first-stage planetary gear set 1060 is connected to the rotor support 1053 in a torque-resistant man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com